-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In recent years, the use of Pultruded Carbon Fiber Bar has gained significant traction across various industries. Experts emphasize the crucial benefits these materials offer. Dr. Emily Hartman, a leading composite materials engineer, states, "The strength-to-weight ratio of Pultruded Carbon Fiber Bar is simply unmatched." This statement highlights the unique advantages of using these bars in construction, automotive, and aerospace applications.

The lightweight nature of Pultruded Carbon Fiber Bar provides superior performance compared to traditional materials like steel or aluminum. Reduced weight often leads to enhanced energy efficiency. Yet, the cost associated with production remains a concern for some businesses. Striking a balance between performance and affordability is a challenge many companies face.

Moreover, the durability of Pultruded Carbon Fiber Bar adds to its appeal. These bars resist corrosion and wear, ensuring longevity. However, end-users must reflect on the proper maintenance practices to maximize their lifespan. Understanding these elements can help industries make informed decisions about integrating Pultruded Carbon Fiber Bar into their operations.

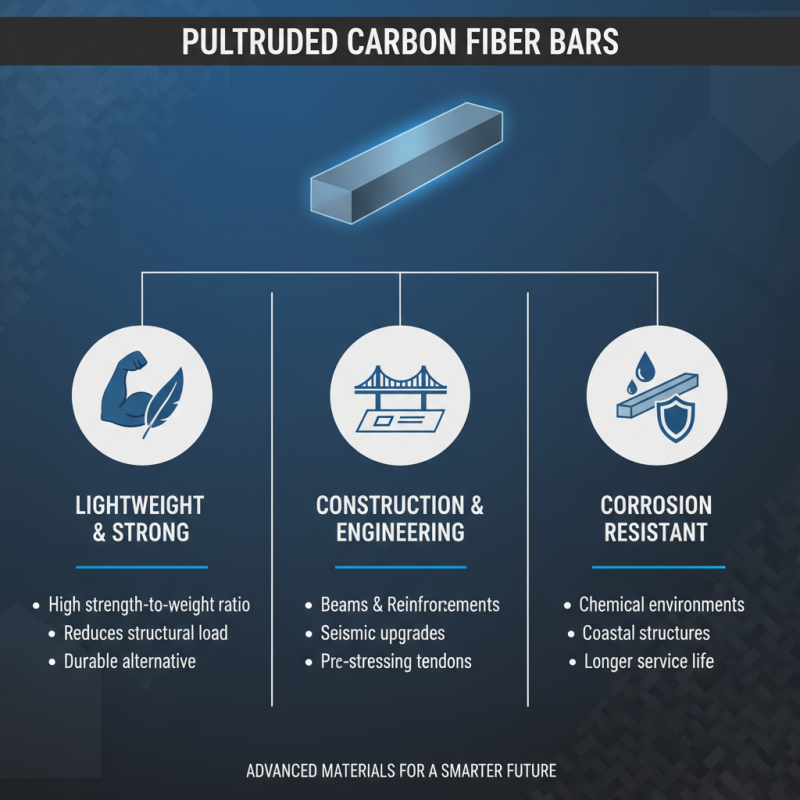

Pultruded carbon fiber bars offer unique advantages across various industries. These bars are known for their lightweight nature and impressive strength. In construction, they enhance structural integrity without adding excessive weight. Engineers often prefer them for beams and reinforcements. Their resistance to corrosion also makes them suitable for environments where traditional materials might fail.

In automotive applications, pultruded carbon fiber bars help improve fuel efficiency. Lightweight components contribute to better performance. It’s interesting to see how the automobile industry is leaning toward these advanced materials. However, cost can be a barrier. Manufacturers face challenges in balancing performance and affordability.

The aerospace sector benefits significantly as well. Here, reducing weight is critical. Pultruded carbon fiber bars support the need for robust yet lightweight designs. However, working with these materials requires specialized knowledge. Some processes can be tricky and demand precision. Also, not every manufacturer offers the same quality, which is worth noting. Each application may require careful consideration to ensure effectiveness.

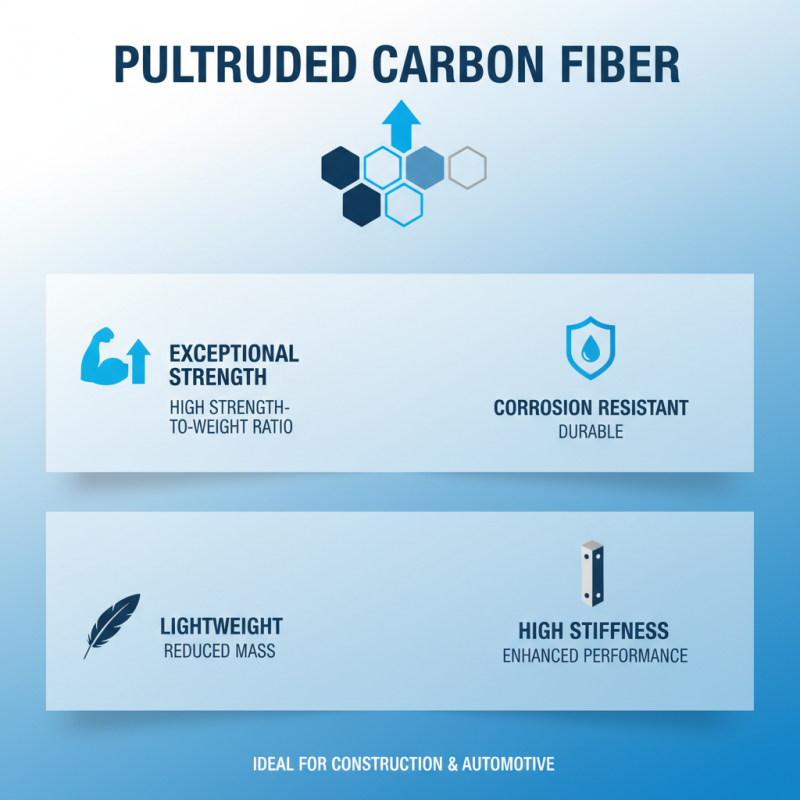

Pultruded carbon fiber is known for its exceptional strength and lightweight properties. This material has a high strength-to-weight ratio, making it ideal for various applications. It is resistant to corrosion, which adds to its durability over time. The stiffness of pultruded carbon fiber enhances its performance in construction and automotive industries. These attributes make it a preferred choice for components requiring both resilience and reduced mass.

One key property is its low thermal expansion. This helps maintain structural integrity under temperature changes. Additionally, it is electrically conductive, which opens doors for applications in electronics. The process of pultrusion allows for continuous production, ensuring consistency in quality. However, it can be more expensive than traditional materials like steel or aluminum. This cost factor often requires careful consideration in project budgets.

Pultruded carbon fiber also exhibits excellent fatigue resistance. This makes it suitable for applications where repeated stress is a factor. Engineers often rely on its reliability in critical situations. Nevertheless, its brittleness can pose challenges. Proper handling and installation are essential to avoid damage. As industries evolve, the exploration of pultruded carbon fiber continues to reveal new opportunities and challenges.

Pultruded carbon fiber bars are revolutionizing various industries with their unique properties. They are lightweight yet extremely strong, making them ideal for construction and aerospace applications.

In construction, these bars provide high tensile strength and flexibility, offering innovative solutions in reinforcement. Their resistance to corrosion makes them suitable for harsh environments.

In the automotive sector, pultruded carbon fiber bars help reduce vehicle weight for improved fuel efficiency. They also offer excellent impact resistance, contributing to safety. In marine applications, these bars withstand saltwater damage, making them a preferred choice for boat manufacturing.

Despite their advantages, challenges remain. The manufacturing process can be costly, which may limit widespread adoption. Moreover, material compatibility in composite structures needs more research. As industries explore these options, understanding both benefits and drawbacks will be crucial in decision-making. There’s always room for improvement in optimizing these materials for performance.

When comparing pultruded carbon fiber bars to other materials, several key factors come into play. Carbon fiber is lightweight yet incredibly strong. Many industries favor it for applications where weight-saving is crucial. Its high tensile strength outperforms metals like aluminum and steel, making it a top choice in demanding environments.

However, it is not without its drawbacks. The cost of carbon fiber tends to be higher, impacting overall project budgets. In contrast, materials like fiberglass are cheaper and easier to work with, but they lack the same strength. Some applications may not justify the expense of carbon fiber bars.

The durability of carbon fiber is notable, especially in corrosive environments. It resists rust and degradation, a significant advantage over metal materials. Yet, issues such as limited repairability and brittleness must be acknowledged. This brittleness can lead to failure under certain stress conditions, raising concerns for critical applications. Ultimately, choices depend on specific project needs and performance requirements. Each material comes with its own set of practical challenges and benefits.

| Material | Tensile Strength (MPa) | Weight (g/cm³) | Corrosion Resistance | Cost ($/kg) | Common Applications |

|---|---|---|---|---|---|

| Pultruded Carbon Fiber Bar | 700-1500 | 1.6 | Excellent | 20-40 | Aerospace, Automotive, Civil Engineering |

| Aluminum | 200-600 | 2.7 | Good | 3-5 | Construction, Transport, Packaging |

| Steel | 250-1000 | 7.85 | Moderate | 1-3 | Infrastructure, Machinery, Tools |

| Fiberglass | 200-400 | 2.5 | Good | 1-3 | Marine, Electrical, Construction |

| Titanium | 600-1400 | 4.5 | Excellent | 30-60 | Aerospace, Medical, Marine |

The carbon fiber bar industry is witnessing significant innovations. Future trends indicate a focus on improving production methods to enhance efficiency. One report projects a growth rate of over 15% in the carbon fiber market by 2028. This increase is driven by various sectors demanding lightweight, high-strength materials.

Sustainability is becoming a critical concern. Companies are exploring recycling methods for carbon fiber, a material typically challenging to repurpose. Innovative approaches in thermoplastic carbon fiber composites may allow easier processing and reuse. Advanced manufacturing techniques could reduce waste and energy consumption.

Moreover, smart materials are emerging. Researchers are developing carbon fiber bars embedded with sensors. These bars can monitor structural health in real-time. The feedback can prevent failures and extend the lifespan of structures. The potential impact on construction and aerospace is considerable, despite logistical challenges during implementation.