-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

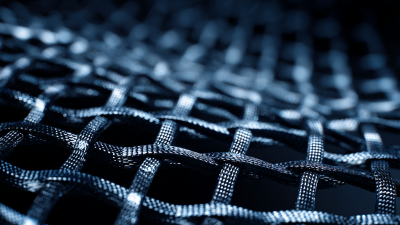

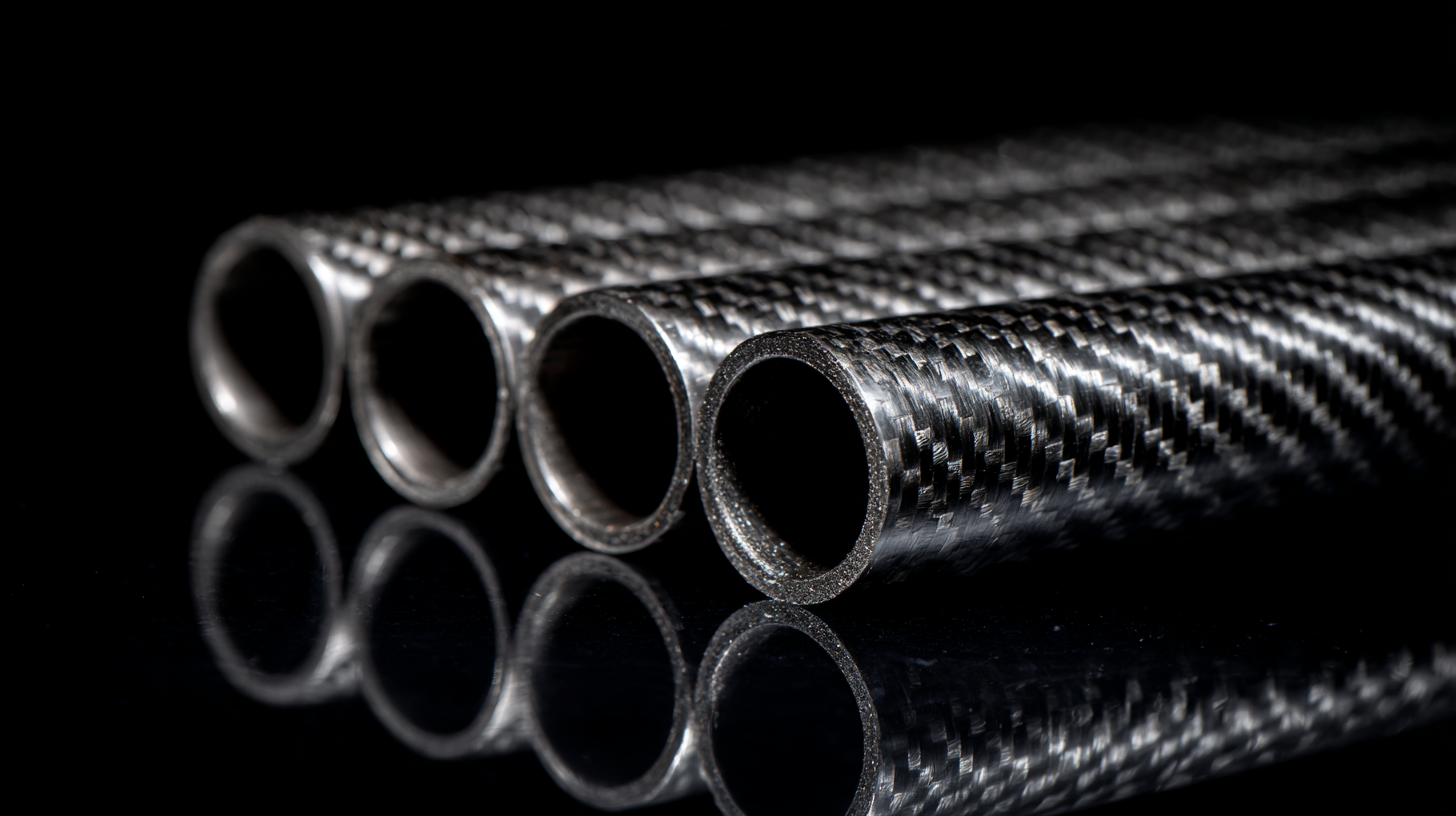

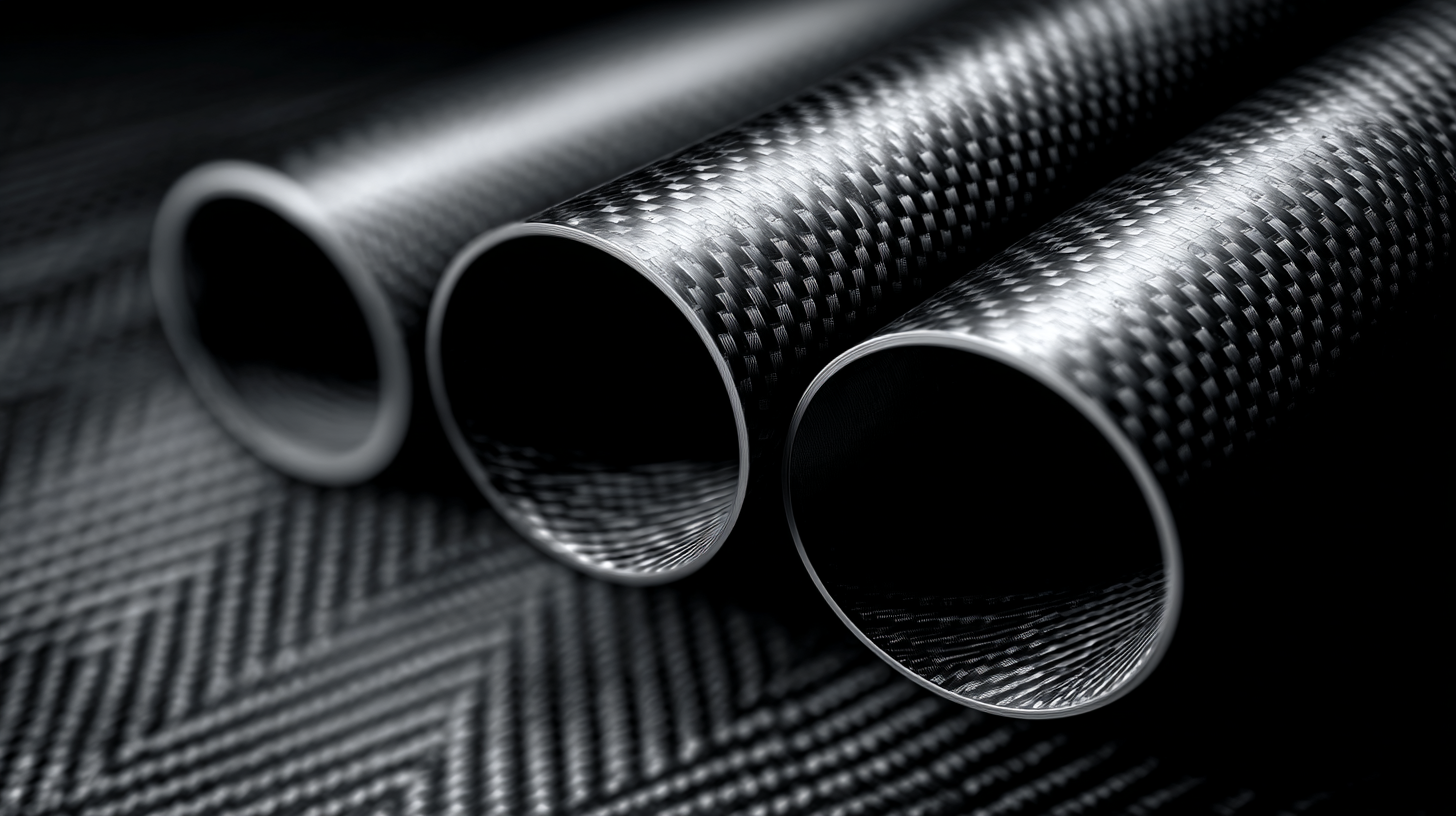

Carbon fiber tubes have emerged as a revolutionary material in various industries due to their exceptional properties, combining lightweight characteristics with extraordinary strength and rigidity. This blog will unveil unique applications of carbon fiber tubes across diverse sectors, highlighting its transformative impact. From aerospace and automotive engineering to sports equipment and medical devices, carbon fiber tubes are reshaping conventional designs and enhancing performance. We will explore five notable industries that are harnessing the advantages of carbon fiber tubes, examining the specific reasons driving their adoption—from improved fuel efficiency in aircraft to enhanced durability in athletic gear. Join us as we delve into the fascinating world of carbon fiber tubes and uncover how they are redefining what's possible in modern manufacturing and design.

The aerospace industry has witnessed a significant shift in material usage, with carbon fiber tubes emerging as a game-changer. Known for their exceptional strength-to-weight ratio, these tubes are not only lightweight but also possess superior stiffness and durability compared to traditional materials like aluminum or steel. This characteristic is paramount in aerospace engineering, where every gram counts in enhancing fuel efficiency and overall performance. As manufacturers aim to meet stringent performance metrics, the incorporation of carbon fiber tubes into aircraft structures, such as fuselages and wing components, is on the rise.

The aerospace industry has witnessed a significant shift in material usage, with carbon fiber tubes emerging as a game-changer. Known for their exceptional strength-to-weight ratio, these tubes are not only lightweight but also possess superior stiffness and durability compared to traditional materials like aluminum or steel. This characteristic is paramount in aerospace engineering, where every gram counts in enhancing fuel efficiency and overall performance. As manufacturers aim to meet stringent performance metrics, the incorporation of carbon fiber tubes into aircraft structures, such as fuselages and wing components, is on the rise.

Moreover, the growing demand for carbon fiber tubes is closely tied to advances in manufacturing technologies, such as automated fiber placement and 3D printing. These innovations enable precise control over material layup, optimizing the design for both strength and weight. As a result, carbon fiber tubes are being utilized in innovative applications, such as unmanned aerial vehicles (UAVs) and next-generation commercial aircraft. This trend not only supports the aerospace sector's move towards sustainability but also positions carbon fiber tubes as a cornerstone of future aerospace engineering practices, ultimately reshaping the landscape of aviation design and functionality.

Carbon fiber tubes are revolutionizing the automotive industry by offering lightweight solutions that significantly enhance fuel efficiency. Traditional materials often compromise performance due to their density, leading to increased fuel consumption. In contrast, carbon fiber’s remarkable strength-to-weight ratio allows manufacturers to redesign vehicle components without sacrificing structural integrity. This transformative aspect not only reduces the overall weight of vehicles but also improves their acceleration and handling, making them more responsive on the road.

The integration of carbon fiber tubes into automotive applications is also a testament to the broader trend of using advanced materials for sustainability. As the need for greener solutions grows, carbon fiber's resistance to corrosion and minimal maintenance requirements present an attractive alternative to conventional materials. Furthermore, the flexibility in design afforded by fiber-reinforced polymers enables engineers to explore innovative configurations that were previously unimaginable, pushing the boundaries of automotive design. By embracing these advanced composites, the automotive sector can contribute to a more efficient and environmentally friendly future while continuing to meet consumer demands for high-performance vehicles.

This bar chart illustrates the various applications of carbon fiber tubes in the automotive industry, showcasing their impact on fuel efficiency across different vehicle types.

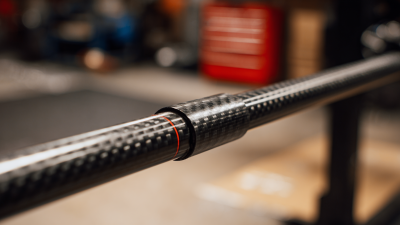

Carbon fiber tubes have revolutionized the sports equipment industry by offering lightweight, high-strength solutions that enhance performance across various disciplines. Athletes and manufacturers are increasingly recognizing the benefits of these advanced materials. For instance, in cycling, carbon fiber tubes allow for lighter frames, making it easier for cyclists to achieve higher speeds without compromising structural integrity. Similarly, in the realm of tennis, racquets featuring carbon fiber construction provide better power and maneuverability, allowing players to improve their game.

**Tips for Incorporating Carbon Fiber in Sports Equipment:**

When considering carbon fiber for sports gear, it's vital to focus on the design and construction process. Ensure that the tubes are tailored to match specific performance needs, be it stiffness for control or flexibility for comfort. Also, explore hybrid designs that combine carbon fiber with other materials for enhanced durability while still benefiting from carbon's lightweight properties.

As technology advances, the potential applications of carbon fiber in sports will only expand. Innovators should stay ahead of trends by continuously researching and testing new composites, leading to cutting-edge products that provide athletes with the competitive edge they seek. For example, experimenting with varying layup orientations can drastically alter the performance characteristics, catering equipment precisely to the demands of each sport.

| Industry | Application | Benefit | Material Properties |

|---|---|---|---|

| Sports Equipment | Bicycles | Lightweight and improved aerodynamics | High tensile strength, low weight |

| Sports Equipment | Golf Clubs | Increased swing speed and control | Stiffness, vibration damping |

| Sports Equipment | Fishing Rods | Enhanced sensitivity and strength | Corrosion resistance, lightweight |

| Sports Equipment | Tennis Rackets | Improved power and precision | Durability, customizable stiffness |

| Sports Equipment | Ski Poles | Reduced fatigue, increased speed | Lightweight, high impact resistance |

Carbon fiber tubes are making significant strides in the healthcare industry, offering innovative solutions that redefine patient care and medical practices. According to a report by MarketsandMarkets, the global carbon fiber market in the healthcare sector is expected to grow at a CAGR of 8.5% from 2021 to 2026, driven by the increasing demand for lightweight and durable materials in medical devices. These tubes are being utilized in surgical instruments, orthopedic braces, and even prosthetics, enhancing performance while minimizing weight for improved mobility and comfort.

When integrating carbon fiber tubes into healthcare applications, consider the importance of their biocompatibility and mechanical properties. Not only do they provide strength and flexibility, but their resistance to corrosion and wear makes them ideal for repeated sterilization processes, which is vital in surgical settings. Healthcare professionals can maximize these benefits by opting for custom-designed carbon fiber solutions tailored to specific medical needs.

Tip: Always consult with a specialized engineer or materials scientist to ensure that the chosen carbon fiber tubes meet all regulatory standards and can withstand the specific demands of medical applications. Additionally, thorough testing should be conducted to guarantee the longevity and reliability of the products in a clinical environment.

The carbon fiber tube manufacturing industry is experiencing rapid growth, projected to reach a market size of approximately $5.23 billion by 2028, according to industry reports. However, production challenges such as material waste, quality control, and cost efficiency continue to pose significant hurdles. In particular, the complex processes involved in resin impregnation and curing can lead to inconsistencies that affect the final product. To mitigate these issues, manufacturers are increasingly adopting advanced technologies such as automated filament winding and precision CNC machining. These innovations not only enhance the structural integrity of carbon fiber tubes but also streamline the production process, ultimately lowering operational costs.

Tips for optimizing carbon fiber tube production include investing in high-quality raw materials and equipment to reduce defect rates. Implementing a thorough quality assurance program can also identify problems early in the production process, thereby minimizing waste. Additionally, leveraging data analytics to monitor production metrics allows for better decision-making and continuous improvement in manufacturing practices. As manufacturers address these challenges head-on, the versatility of carbon fiber tubes will continue to expand across industries such as aerospace, automotive, and sports equipment, showcasing their unique properties and performance advantages.