-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

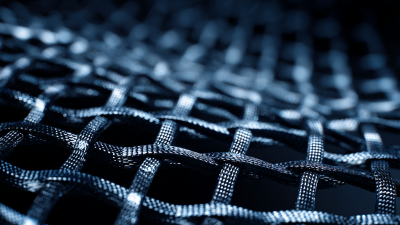

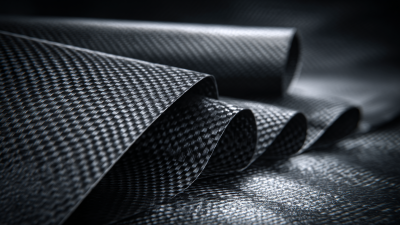

As industries increasingly seek lightweight and high-strength materials, Carbon Fiber Mesh Fabric has emerged as a popular choice in various applications, from automotive to aerospace. According to a recent report by MarketsandMarkets, the global carbon fiber market is projected to reach $5.89 billion by 2026, driven by its superior performance attributes. However, the growing demand for sustainable and cost-effective alternatives is leading innovators to explore unique materials that can deliver similar benefits without the environmental implications associated with carbon fiber production. This blog delves into inventive alternatives to Carbon Fiber Mesh Fabric, examining their potential in innovative applications across multiple sectors, and highlighting how these alternatives can play a pivotal role in shaping the future of material science.

The exploration of aramid fiber as an alternative to carbon fiber in high-performance applications unveils a multitude of benefits. Aramid fibers, known for their exceptional strength and heat resistance, are being increasingly recognized in sectors such as automotive and aerospace. Recent reports indicate that the high-performance fibers market is projected to grow at a CAGR of 8.0%, driven by the demand for lightweight and durable materials. Aramid fibers, especially para-aramid types, have shown significant promise due to their superior tensile strength compared to conventional materials, making them ideal for applications where both performance and weight savings are critical.

Moreover, the sustainability factor of aramid fibers can't be overlooked. With the increasing focus on eco-friendly materials, innovations in production are being validated. For instance, one manufacturer has achieved certification for using alternative feedstocks in fiber production. This move not only highlights aramid's potential as a responsible choice but also positions it as a viable option in a market that seeks to reduce environmental impact.

Tip: When considering material options for your next project, evaluate the specific performance requirements and sustainability goals. Aramid fibers might offer a better balance of strength, weight, and ecological impact compared to traditional carbon fibers. Additionally, consider the latest advancements in 3D printing technology with aramid materials, which can yield custom, high-strength parts with reduced waste.

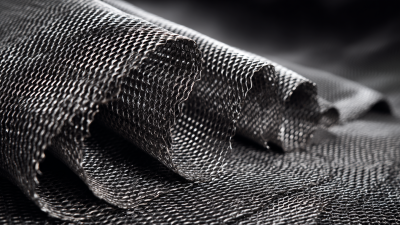

The rising demand for sustainable materials in various industries has led to a surge in interest towards natural fiber composites as alternatives to traditional carbon fiber mesh fabrics. According to a report by ResearchAndMarkets, the global natural fiber composites market is projected to reach USD 6.6 billion by 2025, showcasing a compound annual growth rate (CAGR) of over 10%. This growth is driven by the increasing need for lightweight, eco-friendly solutions in automotive, aerospace, and consumer goods sectors.

Natural fibers, such as jute, hemp, and flax, present numerous advantages, including biodegradability, lower density, and energy-saving production processes. A study published in the Journal of Cleaner Production highlights that integrating natural fibers into composite materials can reduce carbon emissions by up to 75% compared to synthetic fibers. Furthermore, the inherent mechanical properties of these fibers offer a suitable alternative for applications requiring tensile strength without compromising on sustainability. This innovative approach not only addresses environmental concerns but also paves the way for developing high-performance mesh fabrics that align with global sustainability goals.

In recent years, the quest for innovative materials has led to a renaissance in the exploration of glass fiber as a viable alternative to carbon fiber mesh fabric. Known for its excellent strength-to-weight ratio and remarkable tensile strength, glass fiber is becoming increasingly popular in various applications, including automotive, aerospace, and sporting goods. The performance metrics of glass fiber, particularly in mesh applications, showcase its ability to maintain structural integrity while providing flexibility, which is paramount in demanding environments.

In recent years, the quest for innovative materials has led to a renaissance in the exploration of glass fiber as a viable alternative to carbon fiber mesh fabric. Known for its excellent strength-to-weight ratio and remarkable tensile strength, glass fiber is becoming increasingly popular in various applications, including automotive, aerospace, and sporting goods. The performance metrics of glass fiber, particularly in mesh applications, showcase its ability to maintain structural integrity while providing flexibility, which is paramount in demanding environments.

One of the standout characteristics of glass fiber is its resistance to environmental factors such as moisture, chemicals, and extreme temperatures. This durability ensures that glass fiber meshes not only perform well under stress but also have a longer lifespan compared to traditional materials. Additionally, advancements in manufacturing techniques are enabling the production of glass fiber meshes with tailored properties. This adaptability opens the door to innovative applications, allowing designers and engineers to push the boundaries of traditional uses and explore novel solutions across various industries.

The shift towards sustainability in material science has led to an increased interest in biodegradable polymers as alternatives to traditional carbon fiber mesh fabrics. According to a report by MarketsandMarkets, the biodegradable polymers market is projected to grow from $6.3 billion in 2020 to $14.2 billion by 2025, highlighting a significant trend toward eco-friendly materials. These innovative polymers, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are being specifically tailored for diverse applications ranging from automotive components to medical devices, offering not only a reduced environmental impact but also enhanced functionality.

The potential of these biodegradable polymers in mesh fabric technology is particularly promising. A study published in the Journal of Applied Polymer Science indicates that incorporating biodegradable materials can dramatically improve the mechanical properties of mesh fabrics while maintaining their flexibility and durability. This innovation opens up new possibilities for industries looking to reduce their carbon footprint without sacrificing performance. As companies continue to invest in research and development, the future of mesh fabric applications appears bright, with biodegradable options set to redefine standards and pave the way for more sustainable practices across various sectors.

The textile industry is on the brink of a transformation as innovative alternatives to carbon fiber mesh fabric emerge, offering potentially lower costs and enhanced performance characteristics. A recent analysis by Smithers Pira indicates that the global market for carbon fiber is projected to reach $7.5 billion by 2025, with a compound annual growth rate (CAGR) of 10%. However, the high production costs and extensive manufacturing processes associated with carbon fiber remain significant barriers. In contrast, materials like aramid fibers and advanced thermoplastics are gaining traction due to their favorable cost structures, offering similar strength-to-weight ratios without the hefty price tag.

For instance, aramid fibers, such as Kevlar, exhibit impressive tensile strength at nearly half the cost of carbon fiber. A report published by TechNavio highlights that the aramid fiber market is expected to grow by $2.3 billion by 2024, as manufacturers seek cost-effective, durable options. Additionally, innovative alternatives like flax and hemp fibers offer sustainable solutions, boasting lower environmental impacts and cost efficiency. With their revival, these natural fibers can reduce dependency on carbon fiber while appealing to eco-conscious consumers. Through such comparative analyses, it becomes clear that while carbon fiber has dominated the market, evolving materials are set to redefine value propositions within the textile industry.

This chart illustrates the cost comparison of carbon fiber mesh fabric against several innovative textile alternatives, highlighting the potential for cost-effective materials in the textile industry.