-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Selecting the right Carbon Fiber Laminate Sheet for your project is crucial, as this advanced material plays a significant role in various industries, from aerospace to automotive. According to market research by Grand View Research, the global carbon fiber market is expected to reach $5.9 billion by 2025, highlighting the increasing reliance on carbon fiber composites for their unmatched strength-to-weight ratio and durability. Whether you are an engineer designing cutting-edge components or a hobbyist crafting custom parts, understanding the essential factors in choosing the right laminate sheet can greatly impact the success of your project. With the right insights, you can navigate the complexity of specifications, thickness, and fiber orientation to ensure you select a Carbon Fiber Laminate Sheet that meets your specific needs while optimizing performance and cost-efficiency.

When choosing the right carbon fiber laminate sheet for your project, understanding the various types available is crucial. Carbon fiber laminates are primarily categorized by their weave patterns, resin types, and thicknesses. According to a report by Technavio, the global carbon fiber reinforced plastics market is expected to grow by over 35% from 2020 to 2024, highlighting the increasing demand for versatile applications ranging from aerospace to automotive industries.

Different weave patterns, such as plain weave, twill weave, and unidirectional, offer unique mechanical properties suited for distinct applications. Plain weaves provide a balance of strength and flexibility, making them ideal for general applications. In contrast, unidirectional laminates offer superior tensile strength, suitable for high-performance projects requiring maximum load-bearing capabilities. Additionally, the choice of resin—such as epoxy, phenolic, or vinyl ester—significantly affects the laminate’s durability and environmental resistance. A comprehensive understanding of these factors will ensure that the carbon fiber laminate sheet you select meets your project’s specific requirements effectively.

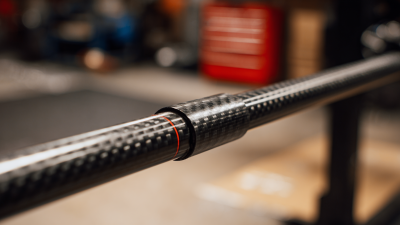

When selecting a carbon fiber laminate sheet for your project, thickness and weight considerations play a pivotal role in ensuring optimal performance. The thickness of the laminate directly influences its strength, rigidity, and durability. Thicker sheets offer enhanced structural integrity, making them suitable for applications requiring high load-bearing capacity. However, this added thickness may contribute to increased weight, which can be a critical drawback in projects where weight savings are paramount, such as in aerospace or high-performance automotive fields. Striking the right balance between thickness and the specific application requirements is essential.

Weight is another critical factor that cannot be overlooked. Carbon fiber is prized for its lightweight nature compared to metals, but the choice of laminate thickness can impact this advantage. A thinner laminate might reduce overall weight, but it could also compromise strength and performance. Thus, it's vital to assess the intended use of the sheet — whether for structural components, aesthetic purposes, or both. Testing different thicknesses and understanding how they affect weight and performance will guide you toward making an informed decision that aligns with your project's goals.

When selecting a carbon fiber laminate sheet for your project, the type of resin you choose plays a crucial role in performance and durability. Different resin systems, such as epoxy and polyester, have unique properties that can greatly affect the mechanical characteristics of the laminate. For instance, epoxy resins offer superior adhesion and thermal stability, making them ideal for applications requiring high strength and temperature resistance.

One essential tip is to evaluate the operating environment of your project. If your application involves exposure to high temperatures or chemicals, opt for a resin that can withstand these conditions. Additionally, consider the cure time of the resin; faster curing options can speed up your manufacturing process, but might sacrifice some performance benefits.

Another important consideration is the weight-to-strength ratio of the laminate. Use a resin that minimizes the overall weight without compromising the structural integrity of the material. For projects demanding lightweight yet robust solutions, a well-matched resin can enhance performance while keeping the laminate manageable. Always consult technical data sheets and professional advice to ensure the resin aligns with your specific project requirements.

| Tip | Description | Resin Type Impact | Recommended Applications |

|---|---|---|---|

| 1. Understand Carbon Fiber Composition | Familiarize with the materials used in carbon fiber laminate sheets. | Different resin types can alter strength and flexibility. | Aerospace & automotive parts. |

| 2. Assess Your Project Requirements | Consider the specific needs for your application. | Resin type affects weight and durability. | Sports equipment & tooling. |

| 3. Evaluate Mechanical Properties | Review tensile strength, impact resistance, and stiffness. | Different resins provide varied mechanical properties. | Industrial applications. |

| 4. Consider Environmental Factors | Analyze factors like temperature and exposure. | Certain resins perform better under harsh conditions. | Marine & outdoor applications. |

| 5. Research Different Resin Options | Investigate epoxy, phenolic, and vinylester resins. | Each resin type provides unique performance benefits. | High-performance and specialized products. |

| 6. Consult Experts | Engage with industry experts for recommendations. | Expert advice tailored to specific resin characteristics. | Custom engineering projects. |

| 7. Perform Cost-Benefit Analysis | Analyze budget against performance needs. | High-performance resins may have higher costs. | Cost-sensitive applications. |

When selecting a carbon fiber laminate sheet for your project, the surface finish can play a pivotal role in both aesthetics and functionality. The surface finish not only impacts the visual appeal but also influences the overall performance and durability of the laminate. Depending on your project requirements, you can choose from several finish options, such as matte, glossy, or textured. A glossy finish can deliver a sleek, modern look, perfect for automotive or high-end consumer goods, while a matte finish might be better suited for applications requiring subtle elegance, such as in cabinetry or furniture design.

For projects where aesthetic appeal is paramount, exploring custom finishes can unleash your creativity. Textured finishes can add depth and dimension to your design, making the laminate visually interesting without overwhelming other elements of the project. Additionally, consider how the surface finish will interact with light; a polished surface can create stunning reflections, whereas a textured surface can diffuse light, enhancing the overall ambiance. By carefully considering your surface finish options, you can elevate your project beyond mere functionality, ensuring that it stands out as a true work of art.

When selecting the right carbon fiber laminate sheets for your project, it's crucial to analyze the balance between cost and quality, particularly in today's environmentally conscious market. Recent industry reports indicate that while carbon fiber offers superior strength-to-weight ratios and durability, the price can vary significantly based on the manufacturing processes and source materials. For instance, the setup cost for carbon fiber manufacturing plants is projected to increase by 2025, emphasizing the need for budget-friendly solutions without compromising quality.

When selecting the right carbon fiber laminate sheets for your project, it's crucial to analyze the balance between cost and quality, particularly in today's environmentally conscious market. Recent industry reports indicate that while carbon fiber offers superior strength-to-weight ratios and durability, the price can vary significantly based on the manufacturing processes and source materials. For instance, the setup cost for carbon fiber manufacturing plants is projected to increase by 2025, emphasizing the need for budget-friendly solutions without compromising quality.

Moreover, as businesses and consumers become increasingly aware of sustainability, there's a growing interest in alternative materials such as natural fiber composites. These alternatives, derived from renewable sources like jute, flax, and hemp, present eco-friendly options capable of achieving competitive performance metrics against traditional carbon fiber. Some reports suggest that these natural fibers not only reduce environmental impact but also cut costs, making them attractive for projects focused on sustainable outcomes. By weighing these factors, you can make informed decisions that align with both your project needs and budget constraints.