-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

The demand for lightweight and high-strength materials has led to the increased use of Carbon Fiber Square Rods across various industries, including aerospace, automotive, and sporting goods. According to a report by Allied Market Research, the global carbon fiber market is projected to reach $5.2 billion by 2025, growing at a CAGR of 10.1% from 2018 to 2025. This surge in popularity is largely attributed to the superior mechanical properties of carbon fiber, such as its impressive strength-to-weight ratio and corrosion resistance. However, users often encounter problems when integrating Carbon Fiber Square Rods into their applications, ranging from cost issues to difficulties in processing and manufacturing. Understanding the best strategies to harness the benefits of these innovative materials is crucial for engineers and manufacturers looking to leverage their unique advantages while overcoming common challenges.

When it comes to materials in engineering and design,

carbon fiber square rods stand out significantly against traditional options like

metal or wood. One of the key advantages of using carbon fiber is its incredible

strength-to-weight ratio. This means you can achieve robust structures without

the added bulk, which is particularly beneficial in applications where weight is crucial, such as in

aerospace and automotive industries.

Tip:

When selecting carbon fiber square rods, consider the specific load requirements of your project. Ensuring that you choose the

correct thickness and density can further enhance performance and durability.

Another notable benefit is the corrosion resistance of carbon fiber. Unlike

metals that can rust or degrade over time, carbon fiber maintains its structural integrity in various environments,

making it an ideal choice for outdoor applications and

marine settings.

Tip:

To maximize the longevity of your carbon fiber components, ensure they are stored away from direct sunlight for extended

periods and cleaned regularly to remove any contaminants that may cause wear.

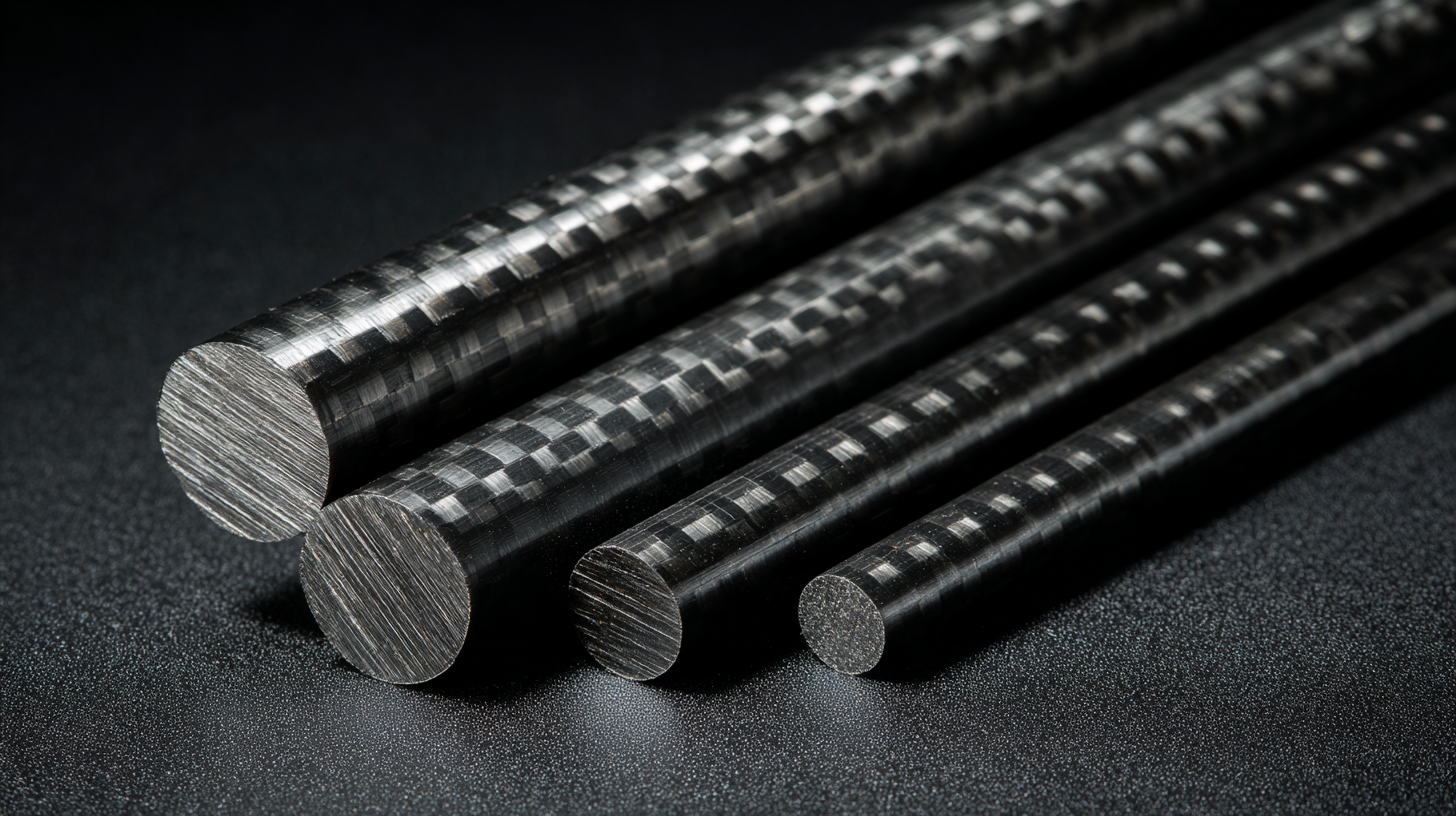

When it comes to selecting the best carbon fiber square rods, understanding their weight, strength, and durability is crucial for maximizing their benefits. Carbon fiber is renowned for being lightweight, allowing for easy handling without sacrificing structural integrity. When comparing various options, always consider how the weight of the rod affects your specific application, whether it's for performance sports, construction, or crafting. A lighter rod can enhance performance, especially in applications where agility and efficiency are key.

Strength is another critical factor when examining carbon fiber square rods. These rods are designed to withstand significant stress and load, making them ideal for applications requiring high performance. Look for rods that offer a high tensile strength-to-weight ratio, as this will ensure that you receive a product that can endure rigorous conditions while remaining lightweight. Remember to check for certifications from manufacturers that guarantee strength standards.

Durability is fundamental when investing in carbon fiber products. Opt for rods with protective coatings that can resist wear, UV damage, and moisture. This is particularly important if they will be used outdoors or in harsh environments. Investing in high-quality carbon fiber rods means you won't have to frequently replace them, leading to long-term savings and reliability in your projects. Always perform a thorough comparison of different brands and their offerings to ensure you choose the optimal square rod for your needs.

When considering the investment in carbon fiber square rods, a thorough cost analysis reveals essential insights into their value compared to traditional materials. Carbon fiber is renowned for its exceptional strength-to-weight ratio, which makes it an attractive option in industries ranging from aerospace to automotive.

While the upfront cost of carbon fiber square rods is typically higher than alternatives like aluminum or steel, their durability and resistance to corrosion can lead to significant long-term savings. This longevity often translates to reduced maintenance costs, as well as fewer replacements over time.

While the upfront cost of carbon fiber square rods is typically higher than alternatives like aluminum or steel, their durability and resistance to corrosion can lead to significant long-term savings. This longevity often translates to reduced maintenance costs, as well as fewer replacements over time.

In contrast, when evaluating alternative materials, it’s crucial to consider not just the initial purchase price but also the overall lifecycle costs. For instance, while aluminum may seem more budget-friendly initially, its susceptibility to wear and tear can result in increased expenditures for repairs or replacements. Additionally, the performance benefits of carbon fiber—such as reduced weight contributing to improved fuel efficiency in vehicles—offer a compelling case for its long-term value proposition. Ultimately, businesses and consumers looking to optimize performance while managing costs should weigh these factors carefully, as the benefits of carbon fiber square rods may well justify their initial investment.

Carbon fiber square rods are becoming increasingly popular across various industries due to their remarkable strength-to-weight ratio and versatility. One of the significant applications of carbon fiber square rods is in construction, where they provide high structural integrity while being lightweight, making them ideal for projects that require superior materials without adding unnecessary weight. Recent innovations, including the development of carbon fiber composites, show promising enhancements in durability and performance, especially in seismic applications where flexibility and strength are crucial.

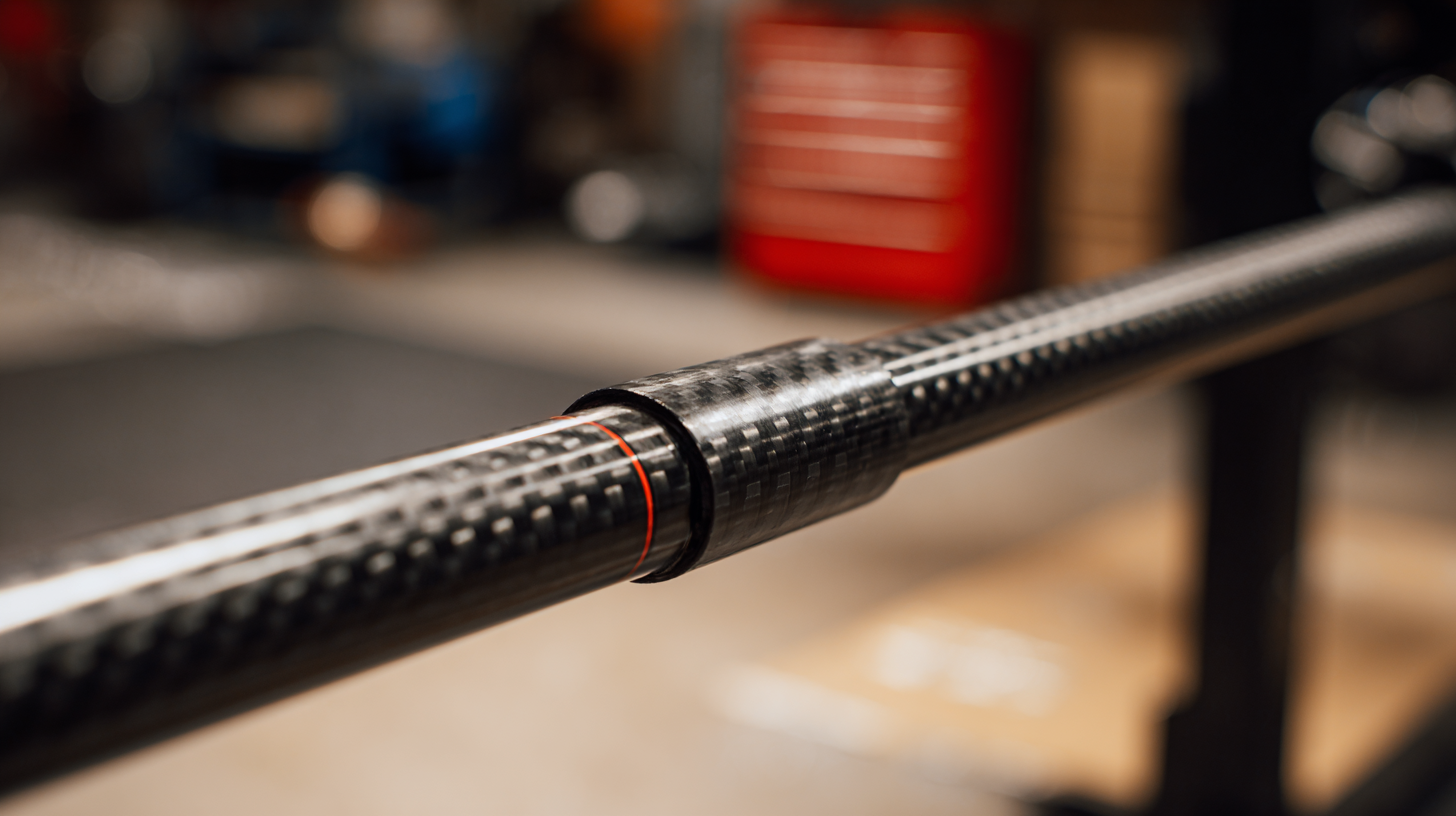

Another compelling use case for carbon fiber square rods is in the manufacturing of composite tubes for various engineering applications. These rods can be tailored in dimensions—for example, the clear distinctions in wall thickness and intermediate diameter significantly affect their mechanical properties and crashworthiness. Industries focused on safety, such as automotive and aerospace engineering, are increasingly leveraging these tailored properties to improve their designs. The ability to produce these rods in various shapes, including square and rectangular forms, enhances their adaptability for specific applications, ensuring that engineers have access to a versatile material that meets diverse project requirements effectively.

When selecting the right carbon fiber square rod for your needs, it's essential to consider a few key factors that can significantly enhance your performance and experience. First, assess the intended use of the rod—whether for structural applications, sporting equipment, or creative projects. Carbon fiber rods are known for their exceptional strength-to-weight ratio, making them ideal for users looking to reduce weight without sacrificing durability.

Consider the dimensions and specifications of the square rod as well. The rod's thickness and length will influence its overall strength and flexibility. If you require a rod for a high-stress application, opt for a thicker profile that offers better resistance against bending or breaking. For more general purposes, a moderately sized rod should suffice, allowing for a balance of lightweight performance and structural integrity.

Lastly, examine the manufacturing quality of the carbon fiber rod. Look for products with a high-grade finish to minimize the chances of defects and ensure longevity. Some brands may even offer specialized variations with additional features like enhanced grip or increased cushioning, tailored for specific applications. Taking these factors into account will help you make an informed decision that aligns perfectly with your unique requirements.