-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

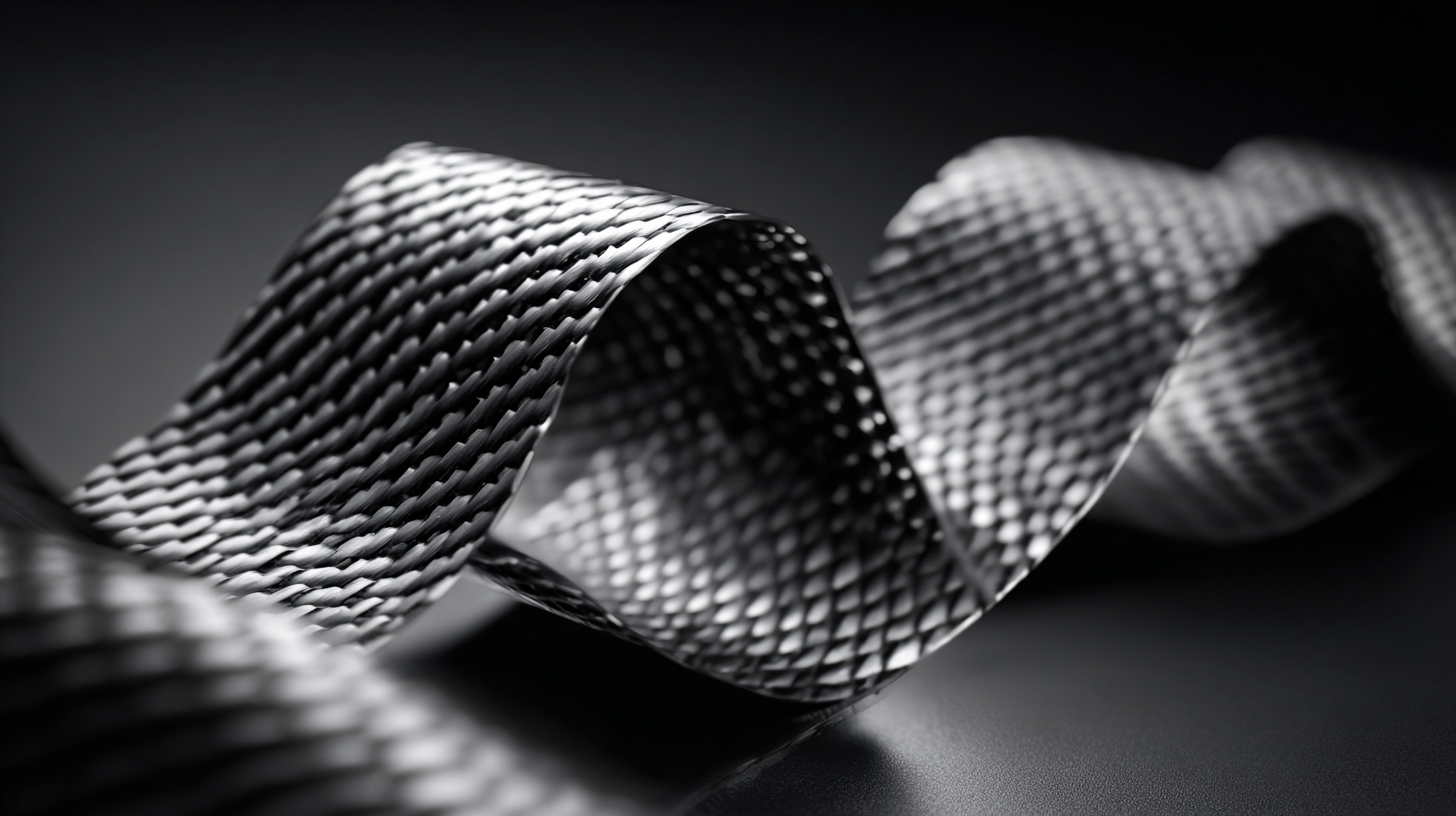

The aerospace manufacturing industry is continuously seeking innovative materials to enhance performance, reduce weight, and improve sustainability. Among these materials, Flexible Carbon Fiber Sheets have emerged as a game-changer, offering unmatched strength-to-weight ratios and exceptional flexibility. According to a recent report by Market Research Future, the global carbon fiber market is expected to reach approximately $30 billion by 2026, driven largely by advancements in aerospace applications. China's leading manufacturers are at the forefront of this revolution, producing high-quality flexible carbon fiber sheets that meet rigorous industry standards. This innovation not only facilitates the design of lightweight structures but also enhances fuel efficiency, which is critical in reducing carbon emissions. As the aviation sector adapts to evolving environmental regulations, these advanced materials are poised to play a vital role in shaping the future of aerospace manufacturing, earning global trust through superior performance and reliability.

The aerospace industry is witnessing a transformative shift with the integration of flexible carbon fiber sheets into manufacturing processes. According to a report by MarketsandMarkets, the carbon fiber market is projected to grow from $3.9 billion in 2022 to $6.1 billion by 2027, highlighting a robust annual growth rate of 9.7%. This surge can be attributed to the lightweight and high-strength properties of carbon fiber, which are crucial in enhancing fuel efficiency and performance in aircraft design. The adaptability of flexible carbon fiber sheets allows manufacturers to leverage their unique properties in producing complex geometries that were previously challenging to achieve with traditional materials.

The aerospace industry is witnessing a transformative shift with the integration of flexible carbon fiber sheets into manufacturing processes. According to a report by MarketsandMarkets, the carbon fiber market is projected to grow from $3.9 billion in 2022 to $6.1 billion by 2027, highlighting a robust annual growth rate of 9.7%. This surge can be attributed to the lightweight and high-strength properties of carbon fiber, which are crucial in enhancing fuel efficiency and performance in aircraft design. The adaptability of flexible carbon fiber sheets allows manufacturers to leverage their unique properties in producing complex geometries that were previously challenging to achieve with traditional materials.

Emerging trends indicate that flexible carbon fiber sheets are not only optimizing structural components but are also paving the way for innovative applications in aerodynamics. A study published in the Journal of Composite Materials notes that these sheets can significantly reduce the overall weight of an aircraft, potentially improving fuel consumption by up to 15%. As aerospace manufacturers continue to invest in advanced materials, flexible carbon fiber sheets stand out for their versatility and ability to withstand harsh environments, thereby solidifying their role in the future of aerospace design and engineering.

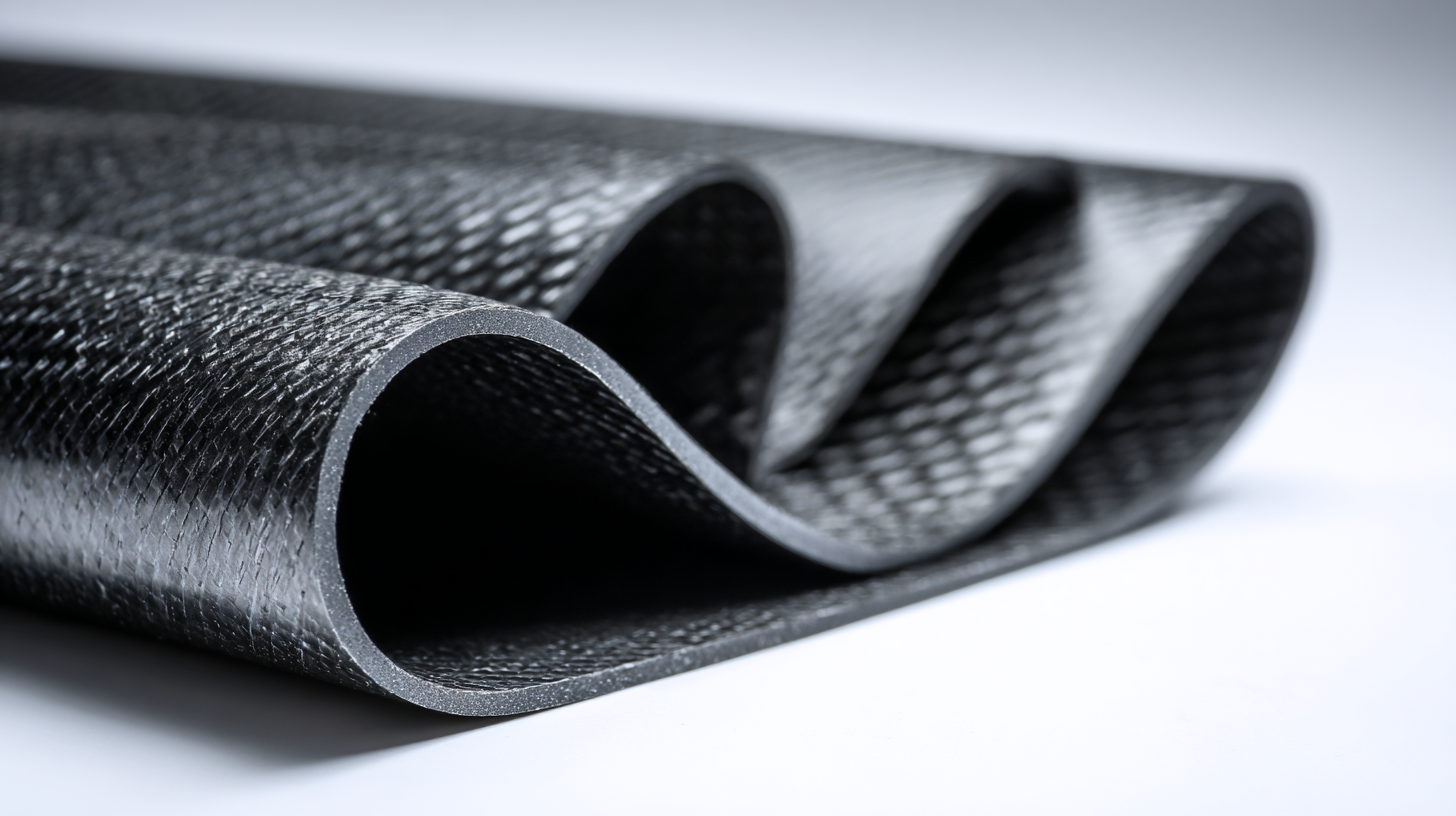

The utilization of flexible carbon fiber sheets in aerospace manufacturing offers remarkable advantages that enhance performance and sustainability. As the aerospace industry strives for lighter, stronger materials, flexible carbon fiber has emerged as a game-changer. According to recent market reports, the global carbon fiber-infused polymers market was valued at approximately USD 18.1 billion in 2024, with an anticipated annual growth rate of 8.6% from 2025 to 2034. This growth is largely driven by the material's ability to significantly reduce weight while maintaining structural integrity, which is crucial for improving fuel efficiency in aircraft.

Furthermore, advancements in manufacturing techniques, such as additive manufacturing, are enhancing the properties and applications of carbon fiber composites in aerospace. Recent studies indicate that carbon nanotube-polymer composites, when combined with flexible carbon fiber sheets, can further improve mechanical properties, allowing for innovative designs that cater to complex aerospace requirements. These materials not only support the structural demands of military and commercial aircraft but also contribute to effective thermal management solutions, making them indispensable in modern aerospace engineering. Ultimately, the versatility and performance of flexible carbon fiber in aerospace manufacturing are setting a new standard for innovative design and sustainability in the industry.

| Application | Key Benefits | Material Properties | Sustainability |

|---|---|---|---|

| Aircraft Structure | Lightweight, High Strength-to-Weight Ratio | High tensile strength, Stiffness | Recyclable components, Reduced emissions |

| Interior Components | Improved Aesthetic Design, Durability | Corrosion-resistant, Lightweight | Sustainable material sourcing, Energy-efficient production |

| Wing Reinforcements | Enhanced Aerodynamic Efficiency | Flexibility, Fatigue resistance | Reduction in waste during manufacturing |

| Propulsion Systems | Noise Reduction, Enhanced Performance | Vibration damping, Thermal stability | Lower lifecycle environmental impact |

| Landing Gear Systems | Increased Safety, Reduced Weight | Impact resistance, Durability | Longer product life, Reduced landfill waste |

Flexible carbon fiber sheets are revolutionizing aircraft design, offering an impressive combination of strength, lightweight properties, and versatility. According to a report by Global Industry Analysts, the aerospace composites market is projected to reach $39.4 billion by 2026, highlighting a growing demand for advanced materials that enhance aircraft performance. These flexible sheets enable designers to create complex shapes and structures that optimize aerodynamics while reducing overall weight, a critical factor in improving fuel efficiency.

Moreover, the use of flexible carbon fiber sheets minimizes assembly time and costs, making them an attractive option for manufacturers. A study by the Composites Innovation Centre found that using advanced composite materials in aircraft production can lead to a weight reduction of up to 30%, significantly improving operational efficiency and extending the lifespan of the aircraft. Additionally, these sheets are not only useful in primary structures but also in interior applications, enhancing passenger comfort without compromising safety or performance. The integration of flexible carbon fiber sheets is set to redefine the aerospace landscape, driving innovation and sustainability in aircraft design.

In recent years, the aerospace industry has increasingly embraced sustainable manufacturing practices, with carbon fiber emerging as a revolutionary material. Best flexible carbon fiber sheets are at the forefront of this transition, offering lightweight yet robust solutions that significantly reduce fuel consumption and emissions in aircraft design. These innovative materials not only enhance performance but also contribute substantially to environmental preservation by decreasing the overall ecological footprint of aviation manufacturing.

Moreover, the adaptability of carbon fiber allows manufacturers to engage in more sustainable processes, such as near-net-shape fabrication, which minimizes waste during production. By harnessing cutting-edge techniques and integrating best flexible carbon fiber sheets into their manufacturing processes, aerospace companies can meet the high standards of safety and efficiency while promoting a greener future. This shift towards sustainable practices is not just a trend; it is a strategic evolution that prioritizes both performance and environmental responsibility, ultimately ensuring the longevity and resilience of the aerospace sector in a rapidly changing world.

As China steps into the limelight of aerospace technology, its innovations around flexible carbon fiber sheets are setting a global precedent. The country is rapidly advancing in the mass production of ultra-strong carbon fibers, positioning itself as a leader in high-tech manufacturing. This progress is not only enhancing China's export capacity but also fostering international partnerships, all while supplementing the larger "Made in China 2025" initiative aimed at cementing its dominance in advanced industries. According to industry reports, China now accounts for nearly two-thirds of the global electric vehicle market, showcasing its manufacturing prowess that extends into aerospace applications.

Tips: When considering aerospace materials, focus on weight-to-strength ratios. For manufacturers, utilizing advanced materials like flexible carbon fiber sheets can significantly reduce aircraft weight while enhancing structural integrity. Moreover, investing in research and development can lead to innovative applications, increasing competitiveness in the global market.

With the international trade climate evolving post-2024 elections, Chinese aerospace innovations are poised to impact global supply chains. The introduction of advanced materials may disrupt traditional markets, allowing nations to leverage China’s advancements. As businesses navigate this landscape, establishing collaborative ventures with Chinese firms could be a strategic advantage, enabling shared technology and best practices in aerospace manufacturing.