-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

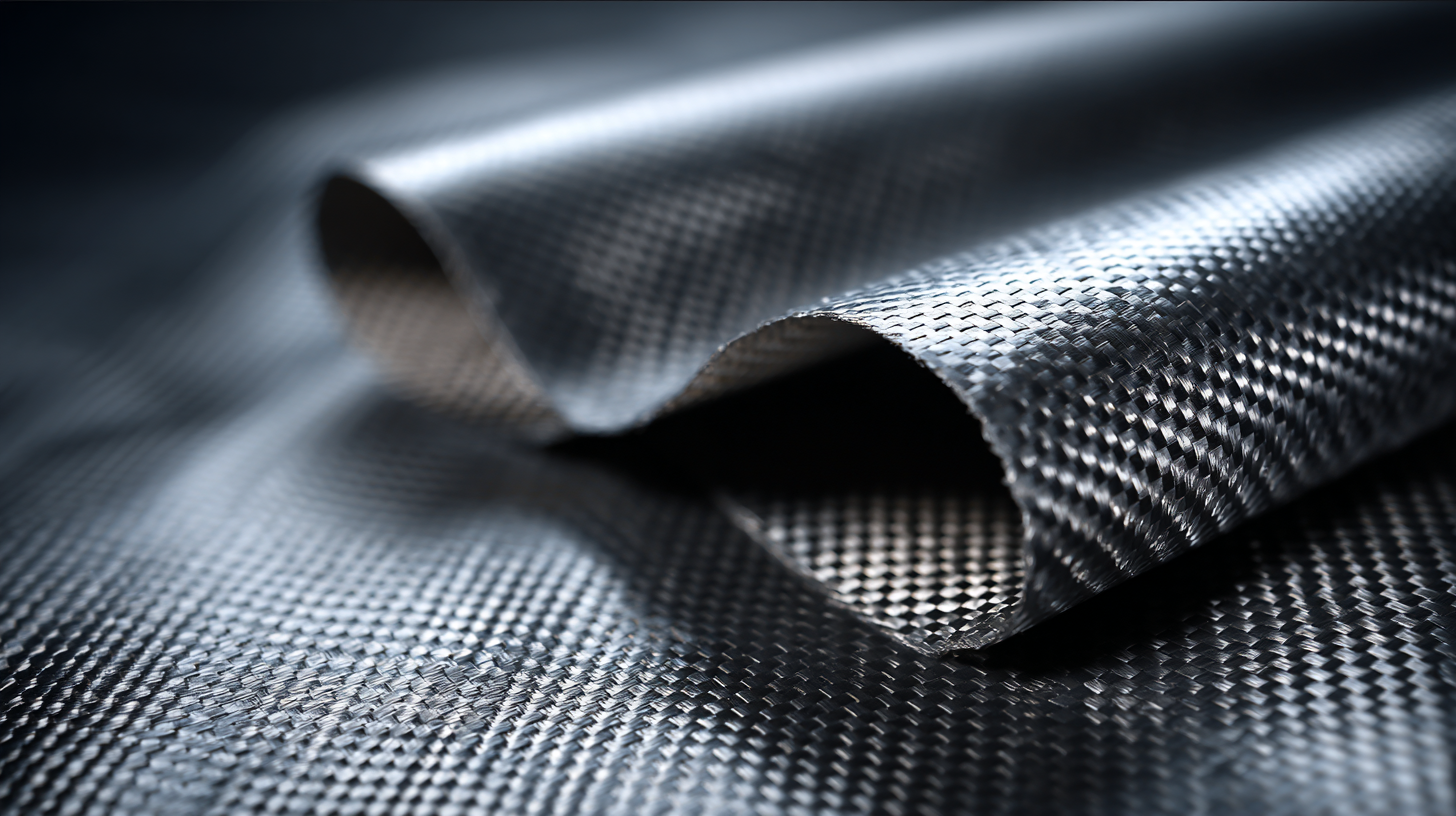

In recent years, the demand for high-quality Carbon Fiber Fabric has surged globally, with China emerging as a leading supplier recognized for its unmatched quality and performance. According to a report by the MarketsandMarkets research firm, the global market for carbon fiber is projected to reach USD 5.25 billion by 2025, growing at a compound annual growth rate (CAGR) of 10.4%. This remarkable growth can be attributed to the increasing adoption of carbon fibers in various industries, including aerospace, automotive, and sports equipment, where strength-to-weight ratio is crucial. Furthermore, international buyers are increasingly turning to Chinese manufacturers, drawn by their advanced production techniques and adherence to stringent export certifications, ensuring that the Carbon Fiber Fabric meets global standards. As the industry evolves, understanding the intricacies of import/export certifications becomes essential for maintaining competitive advantages and guaranteeing product integrity in this booming market.

The global demand for high-quality carbon fiber fabric from China is surging, driven by its unmatched quality and superior performance. This rise in demand can be attributed to various factors, including advancements in manufacturing technologies and the increasing application of carbon fiber in diverse industries such as automotive, aerospace, and sports equipment. The ability of Chinese manufacturers to produce carbon fiber fabrics that are not only lightweight but also extremely strong makes them a preferred choice among global buyers.

Additionally, the emergence of markets like the 3D woven fabric sector further highlights the growing trend towards advanced materials. With projections estimating the 3D woven fabric market to grow significantly by 2033, the relevance of high-quality carbon fiber fabric cannot be understated. Its unique characteristics, achieved through innovative processing methods such as polyacrylonitrile carbonization, position it as a pivotal player in the evolving landscape of industrial materials. As industries continue to prioritize performance and sustainability, the influence of China's carbon fiber manufacturing capabilities will undoubtedly shape market dynamics on a global scale.

In recent years, carbon fiber fabrics produced in China have become a preferred choice for global buyers due to their exceptional quality and performance metrics, particularly in strength, weight, and durability. The demand for high-performance fibers is rapidly growing across sectors such as defense, aerospace, and automotive, driven by their superior strength-to-weight ratio. This characteristic not only enhances the efficiency of products made with carbon fiber but also contributes to reduced overall material costs, making them an attractive option for manufacturers and consumers alike.

Recent advancements in composite materials have pushed the boundaries of what's possible with carbon fiber fabrics, including innovations such as hybrid graphene/carbon fiber composites. These developments aim to improve interfacial properties and mechanical performance, enhancing the durability of the final products. Furthermore, the ongoing focus on sustainability has led to the exploration of eco-friendly materials, such as bamboo fiber reinforced composites, which offer promising alternatives to conventional fibers. This evolving landscape underscores the importance of key performance metrics like strength, weight, and durability as the industry moves toward more advanced and sustainable solutions.

As the global demand for high-quality carbon fiber fabric surges, especially within the automotive industry, production standards across various countries are coming under scrutiny. A recent analysis highlights that the lightweight automotive body panel market is projected to grow from $196.24 billion in 2024 to $310.39 billion by 2032, demonstrating a compound annual growth rate (CAGR) of 5.9%. This booming market underscores the importance of superior materials like carbon fiber, which are pivotal in enhancing vehicle performance while minimizing weight.

In comparing production standards, it is essential to note the rising environmental awareness that is driving changes in material sourcing and recycling practices. The clothing recycling market, anticipated to expand significantly from 2025 to 2035, reflects this trend by addressing the staggering 21 billion pounds of textiles sent to landfills annually. As manufacturers strive to meet consumer demand for sustainable practices, carbon fiber production will likely evolve alongside these shifts, solidifying the reputation of countries like China as leaders in high-quality fabric manufacturing.

The demand for carbon fiber fabric is experiencing a substantial surge, particularly in the aerospace and automotive industries. Industry reports indicate that the global market for carbon fiber is expected to grow from approximately $4.5 billion in 2023 to $9.3 billion by 2030, with a compound annual growth rate (CAGR) of 11.1%. The aerospace sector is the largest consumer, driven by the need for lightweight materials that enhance fuel efficiency and reduce emissions. Carbon fiber components can reduce aircraft weight by up to 20%, translating into significant operational cost savings.

In the automotive industry, the trend towards electric vehicles (EVs) is further propelling the demand for carbon fiber fabric. As manufacturers seek to improve efficiency and performance, the integration of carbon fiber is seen as essential. For instance, a study by the International Council on Clean Transportation highlights that reducing the weight of vehicles by 10% can improve fuel economy by about 6-8%. This growing focus on sustainability and performance is driving global buyers to choose high-quality carbon fiber fabric, particularly from manufacturers in China, which have established a reputation for unmatched quality and innovation in production techniques.

In recent years, China has emerged as a leader in the carbon fiber industry, particularly due to its emphasis on sustainable production methods. According to a report by the Global Carbon Fiber Market, the demand for eco-friendly materials is projected to grow at a CAGR of 10% from 2022 to 2027. This aligns with China's innovative approach to manufacturing, which focuses on reducing carbon emissions and enhancing recycling processes. For instance, many Chinese manufacturers have adopted solutions such as closed-loop systems that recycle raw materials and energy, significantly lowering their environmental footprint.

Moreover, Chinese companies are increasingly investing in research and development to create bio-based precursors for carbon fiber production. A recent study by the Chinese Academy of Sciences highlighted that using sustainable materials could decrease the reliance on petroleum-based products by over 50% by 2025. This shift not only contributes to carbon neutrality goals but also positions China as a frontrunner in sustainability within the global market, appealing to environmentally-conscious buyers seeking high-performance materials with a lower impact on the planet.