-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

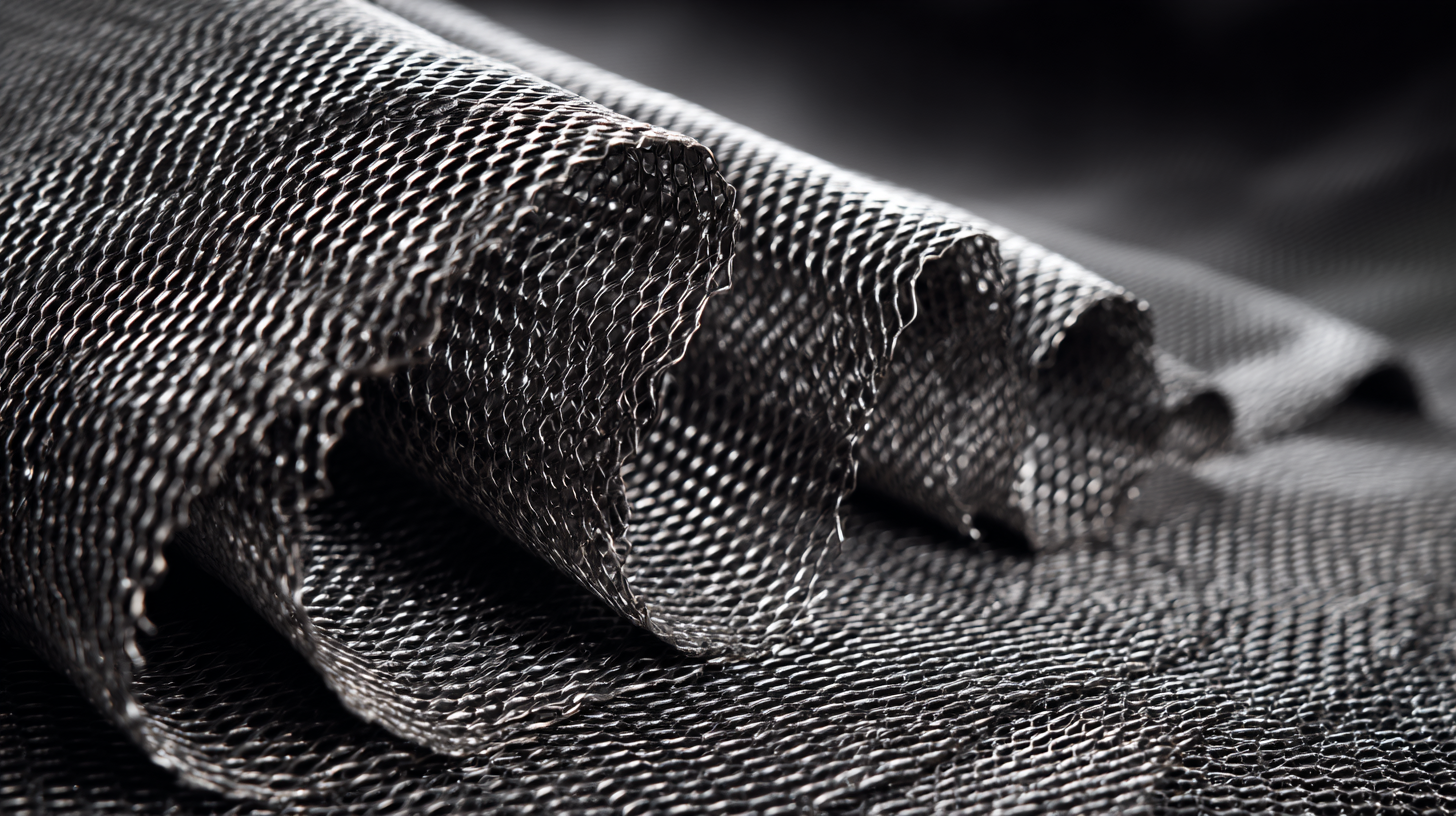

As we approach 2025, the Carbon Fibre Mesh market is poised for significant evolution, driven by advancements in material science and increasing applications across various industries. According to a recent report by Research and Markets, the global carbon fibre market is projected to reach $5.32 billion by 2026, with a substantial portion attributed to the growing demand for carbon fibre mesh in aerospace, automotive, and construction sectors. The lightweight, high-strength properties of carbon fibre mesh make it an ideal choice for enhancing structural integrity and performance. In this blog, we will explore future trends, emerging technologies, and case studies that illustrate the innovative uses of Carbon Fibre Mesh, highlighting its transformative potential in modern engineering and design. Join us as we delve into the insights that will shape the future landscape of this dynamic market.

In the upcoming years, discerning high-quality carbon fibre mesh suppliers will play a crucial role in shaping the market landscape. Understanding the key characteristics of these suppliers can significantly impact your procurement strategies. Quality assurance, manufacturing capabilities, and customer service should be at the forefront of your evaluations. Suppliers who emphasize consistent quality control processes and possess certifications can often deliver products that meet stringent performance standards.

**Tips:** When assessing potential suppliers, consider their experience in the industry and any case studies showcasing their products in real-world applications. Additionally, establishing a strong communication channel will facilitate easier collaboration and problem resolution. Always ask for samples before committing to large orders to ensure the material meets your project specifications.

Another essential factor is innovation in technology. Suppliers who invest in research and development are more likely to offer advanced carbon fibre mesh products with improved functionalities. Regularly reviewing suppliers' product portfolios can reveal cutting-edge options that may provide a competitive edge in your projects.

This chart represents the projected market insights for the carbon fibre mesh industry in 2025. It compares the estimated market share of different applications such as aerospace, automotive, sports equipment, and construction. These insights help identify key characteristics of high-quality carbon fibre mesh suppliers based on application demand.

As the carbon fibre mesh market continues to evolve, assessing supplier reliability and quality is crucial for businesses aiming to stay competitive by 2025. One of the top strategies is to conduct thorough background checks on suppliers. This includes investigating their production capabilities, history, and customer reviews. Companies should prioritize suppliers with a proven track record of consistent quality and timely delivery.

Another key strategy is to establish clear communication channels. Regular interactions with suppliers can foster transparency and build trust. Schedule regular meetings or updates to discuss product specifications, quality control measures, and any potential concerns. This proactive approach not only helps in monitoring supplier performance but also in quickly addressing issues as they arise.

**Tip:** Create a scorecard to evaluate suppliers based on key criteria such as quality certifications, production capacity, and responsiveness. This structured method can simplify the decision-making process and ensure all aspects of supplier reliability are considered. Additionally, don't hesitate to request sample products for in-depth analysis before finalizing any agreements, ensuring that the quality meets your standards.

| Dimension | Description | Value |

|---|---|---|

| Market Growth Rate | Projected annual growth rate of carbon fibre mesh market | 7.5% |

| Key Applications | Industries utilizing carbon fibre mesh | Aerospace, Automotive, Sports Equipment |

| Sustainability Rating | Evaluation of environmental impact of production | High |

| Supplier Reliability Score | Metric for assessing long-term supplier stability | 85/100 |

| Quality Assurance Standards | Benchmark for product quality in the market | ISO 9001 |

| Market Size (2025) | Estimated total value of carbon fibre mesh market | $1.2 Billion |

The carbon fibre mesh market is on the brink of significant innovation, driven by advancements in production techniques and material science. According to a report by MarketsandMarkets, the global carbon fibre market is projected to grow from USD 3.5 billion in 2020 to USD 5.7 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 10.1%. This growth is largely fueled by increased demand in various sectors, including aerospace, automotive, and construction, which are seeking lightweight yet strong materials to enhance efficiency and performance.

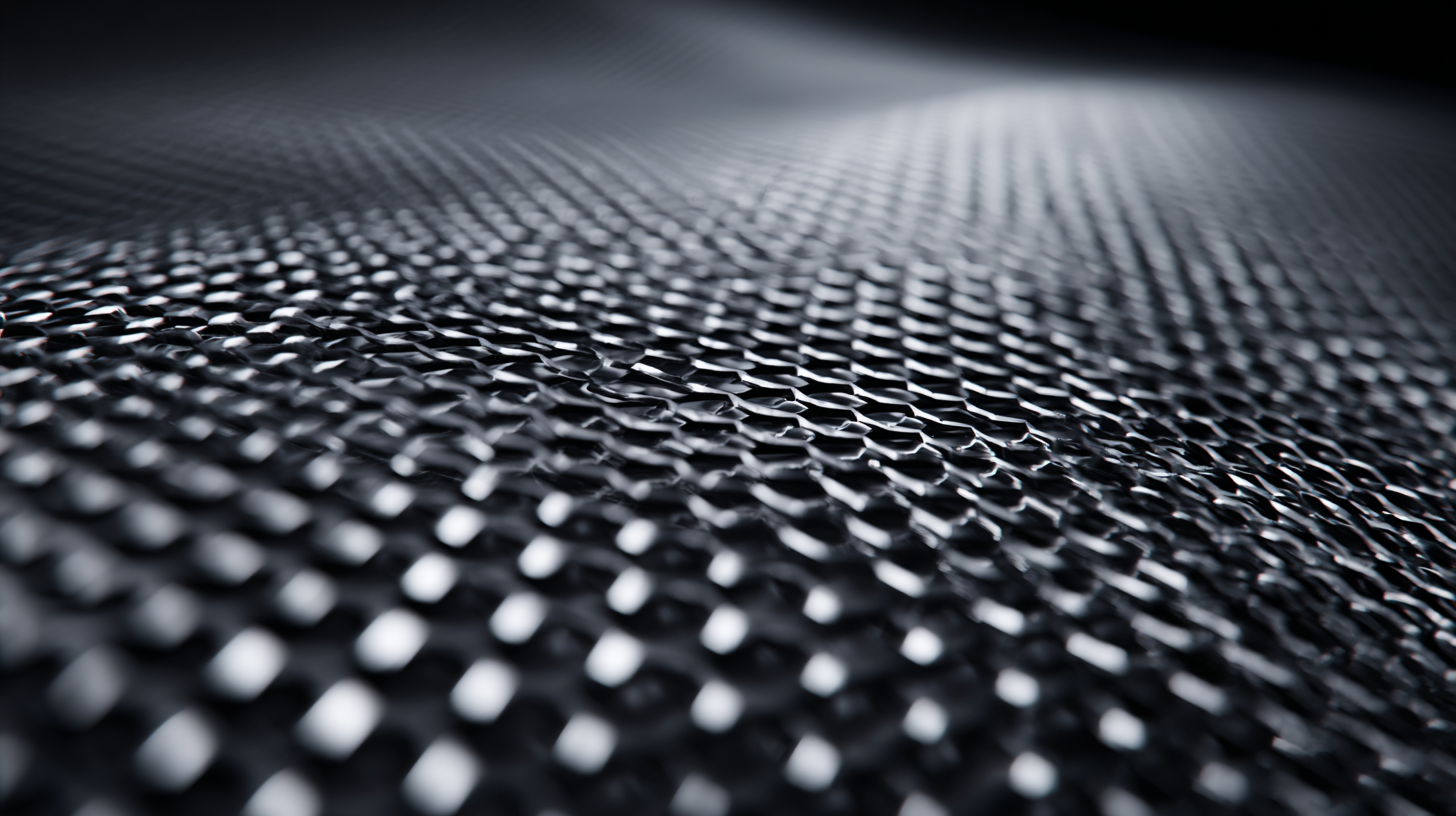

Recent studies highlight several key trends in carbon fibre mesh production. One notable trend is the shift towards automated production processes that improve consistency and reduce waste. As noted in a technical paper published by Composites Research, advancements in resin transfer molding (RTM) and automated fiber placement (AFP) technologies are streamlining the manufacturing process, resulting in higher quality products with lower production costs. Moreover, the incorporation of sustainable practices, such as recycling carbon fibres and utilizing bio-based resins, is gaining traction, aligning with global efforts to reduce environmental impact while meeting increasing consumer expectations for sustainability.

The evolving landscape of the carbon fibre mesh market is increasingly characterized by successful partnerships between manufacturers and suppliers, which are critical for innovation and sustainability. Noteworthy examples include collaborations between leading automotive companies and carbon fibre producers that have resulted in lightweight yet robust vehicle components. These partnerships emphasize not only the performance benefits of carbon fibre mesh but also its role in supporting eco-efficient production processes, aligning with the broader trend of industry sustainability.

Another compelling case study can be observed in the aerospace sector, where leading aircraft manufacturers have partnered with carbon fibre mesh suppliers to enhance structural integrity while reducing overall weight. These alliances focus on developing advanced materials that meet stringent safety and performance standards. The integration of smart technologies in carbon fibre production, alongside a commitment to research and development, further illustrates the potential of collaborative efforts to lead to breakthroughs that will define the future of the carbon fibre mesh industry by 2025.

As industries increasingly embrace sustainability, the selection of carbon fibre mesh materials is becoming a critical challenge. Companies need to navigate the complexities of varying qualities, manufacturers, and applications of carbon fibre mesh to ensure they choose the best option for their specific needs. Proper selection involves not only understanding the mechanical properties of the mesh but also its compatibility with existing manufacturing processes and end-use requirements.

In addition to material properties, environmental impact considerations are becoming paramount. Manufacturers are now faced with the challenge of sourcing carbon fibre mesh that aligns with both performance expectations and sustainability goals. By evaluating case studies from pioneering companies, organizations can gain insights into best practices for material selection and identify potential pitfalls. The shift toward more transparent supply chains can also aid in making informed decisions, ensuring that the chosen carbon fibre mesh not only meets technical specifications but also contributes positively to environmental initiatives.