-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

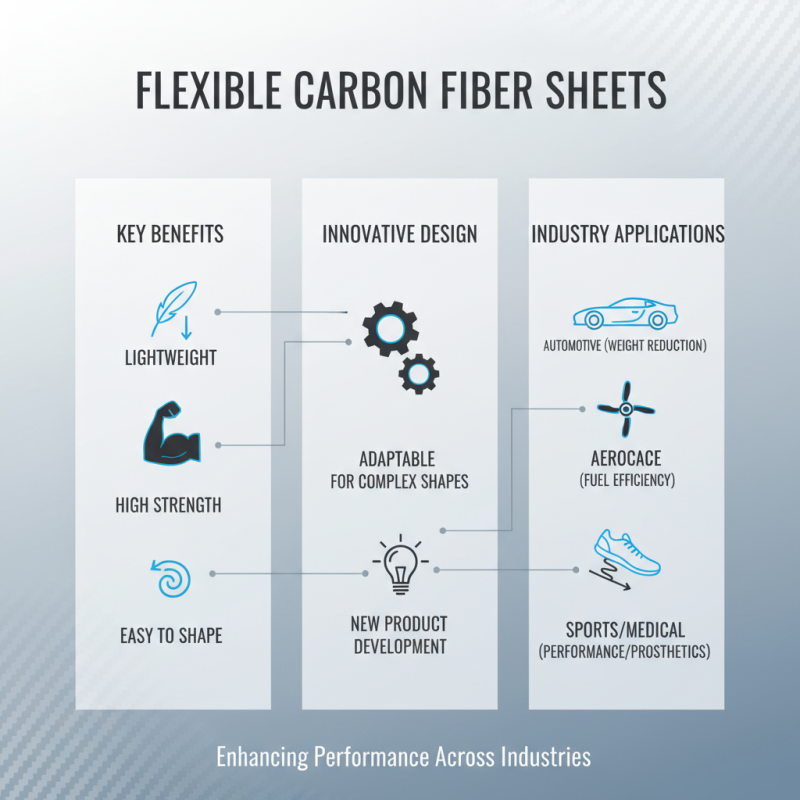

Flexible Carbon Fiber Sheets have revolutionized various industries due to their unique properties. Industry expert Dr. Emily Hartman states, "These sheets are lightweight yet incredibly strong, making them ideal for countless applications." This versatility is what attracts engineers and designers alike.

When considering the best applications for Flexible Carbon Fiber Sheets, it’s essential to understand their capabilities. They are not only durable but also flexible, allowing for innovative designs in automotive and aerospace fields. However, the key lies in selecting the right thickness and weave to match specific project needs. Some users struggle with this aspect, often choosing the wrong specifications. This can lead to underperformance or unnecessary costs.

Exploring the potential uses in areas like sports equipment or protective gear reveals exciting possibilities. Yet, industry insiders often note that not every project requires this advanced material. We must reflect on whether an investment in Flexible Carbon Fiber Sheets aligns with practical needs rather than just the latest trends.

Flexible carbon fiber sheets are revolutionizing various industries due to their unique properties. These sheets are lightweight but exceptionally strong, boasting a tensile strength approximately five times greater than steel. They can withstand harsh environmental conditions, making them suitable for diverse applications, from aerospace to automotive industries.

The flexibility of these sheets allows for easy manipulation and integration into complex designs. They can be molded into intricate shapes which traditional materials often cannot handle. Many engineers report that using flexible carbon fiber can reduce the overall weight of components by up to 30%. However, challenges persist. Achieving the perfect balance between flexibility and rigidity can be tricky. Overly flexible sheets may not provide the necessary support in critical applications.

Understanding the specific needs of your project is key. Research indicates that varying resin types or core materials can significantly influence the performance of carbon fiber sheets. For example, an epoxy resin offers superior adhesion but can be less flexible than alternatives. Choosing the right combination ensures optimal performance, yet, this requires thorough testing and sometimes, costly trial and error.

Flexible carbon fiber sheets have gained popularity in diverse industries due to their remarkable strength-to-weight ratio. According to a recent market analysis, the carbon fiber composites market is projected to reach $44 billion by 2026. This growth reflects the increasing demand for lightweight materials that do not compromise strength.

One of the key benefits of using flexible carbon fiber sheets is their versatility. They can be molded into various shapes, making them suitable for applications in aerospace, automotive, and sporting goods. These sheets typically exhibit tensile strengths exceeding 600 MPa, which is substantial for many engineering applications. However, achieving the desired shape without compromising structural integrity can sometimes be a challenge.

Additionally, flexible carbon fiber sheets resist temperature fluctuations and corrosion. This quality makes them ideal for high-performance environments. For example, they perform well in extreme weather or exposure to chemicals. Yet, not all applications may see immediate benefits. Some users find the initial investment costly, leading to hesitation. Understanding the material's properties and potential applications may require expert insight. That said, their long-term benefits often outweigh initial concerns.

When working with flexible carbon fiber sheets, correct cutting and shaping are vital for optimal results. Begin by using a sharp utility knife or scissors. Ensure your workspace is clean and organized. Always wear safety gear; carbon fibers can be irritating. Mark your lines clearly before cutting. This can save you from making mistakes.

Here are some tips to enhance your cutting experience:

When shaping these sheets, use heat to aid the process. A heat gun can soften the material, making shaping easier. However, be cautious not to overheat, as this could damage the fibers. Creating templates before final cuts can also be beneficial. Experimentation is essential—don’t be afraid to try different techniques.

Flexible carbon fiber sheets are becoming popular in many industries. Their lightweight and strength make them ideal for various applications. They can be shaped easily, allowing for innovative design solutions. For example, in the automotive industry, these sheets can enhance vehicle performance by reducing weight.

In sports equipment, flexible carbon fiber sheets are often used. They improve the durability of items like bicycles and skis. However, it’s important to consider the specific needs of an application. Not every product benefits from carbon fiber. Sometimes, traditional materials might perform just as well.

Another area to explore is the medical industry. These sheets can be used for prosthetics. They offer a balance of flexibility and rigidity. This can significantly improve user comfort. However, the cost can also be a drawback. Sometimes, it’s necessary to weigh the benefits against the expense. Each application requires careful consideration and planning.

Maintaining carbon fiber sheets is essential for their longevity. Regular cleaning can prevent dirt accumulation. Use a soft cloth with mild soap. Avoid harsh chemicals; they can degrade the surface.

Inspect your carbon fiber sheets frequently. Look for scratches or dents. Small damages can grow if ignored. For deeper scratches, consider using fine sandpaper. Be gentle. Too much pressure can worsen the problem.

Storage matters, too. Keep sheets in a dry place. Avoid areas with extreme temperatures. Prolonged heat can warp them. When stacking, use spacers to prevent pressure marks. Each step counts in maintenance. These simple tips can enhance the lifespan of your carbon fiber sheets, ensuring they remain functional and visually appealing.