-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

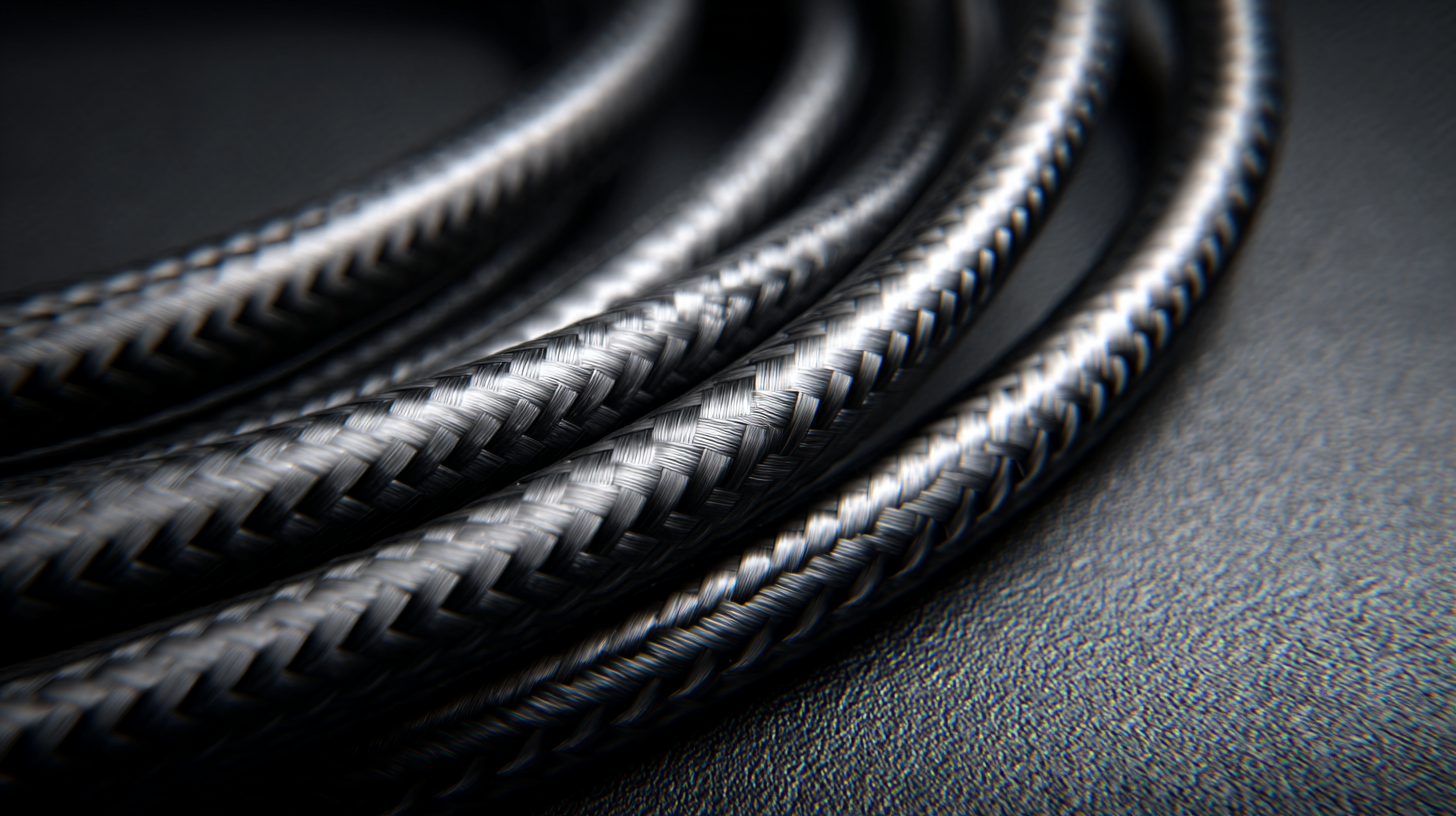

As industries increasingly seek lightweight yet strong materials, the demand for Pultruded Carbon Fiber Bars has surged, driven by advancements in technology and engineering. According to industry reports, the global carbon fiber market is projected to reach $5.49 billion by 2025, reflecting a compound annual growth rate (CAGR) of approximately 10%. This robust growth highlights the importance of exploring not only the best Pultruded Carbon Fiber Bars but also alternative options that may offer similar benefits. As we delve into the 2025 technology trends, including innovations in manufacturing processes and material sciences, it’s essential to evaluate how these alternative solutions can meet the evolving needs of various applications. This exploration will provide insights into the strengths, weaknesses, and future potential of different materials in comparison to traditional pultruded carbon fiber.

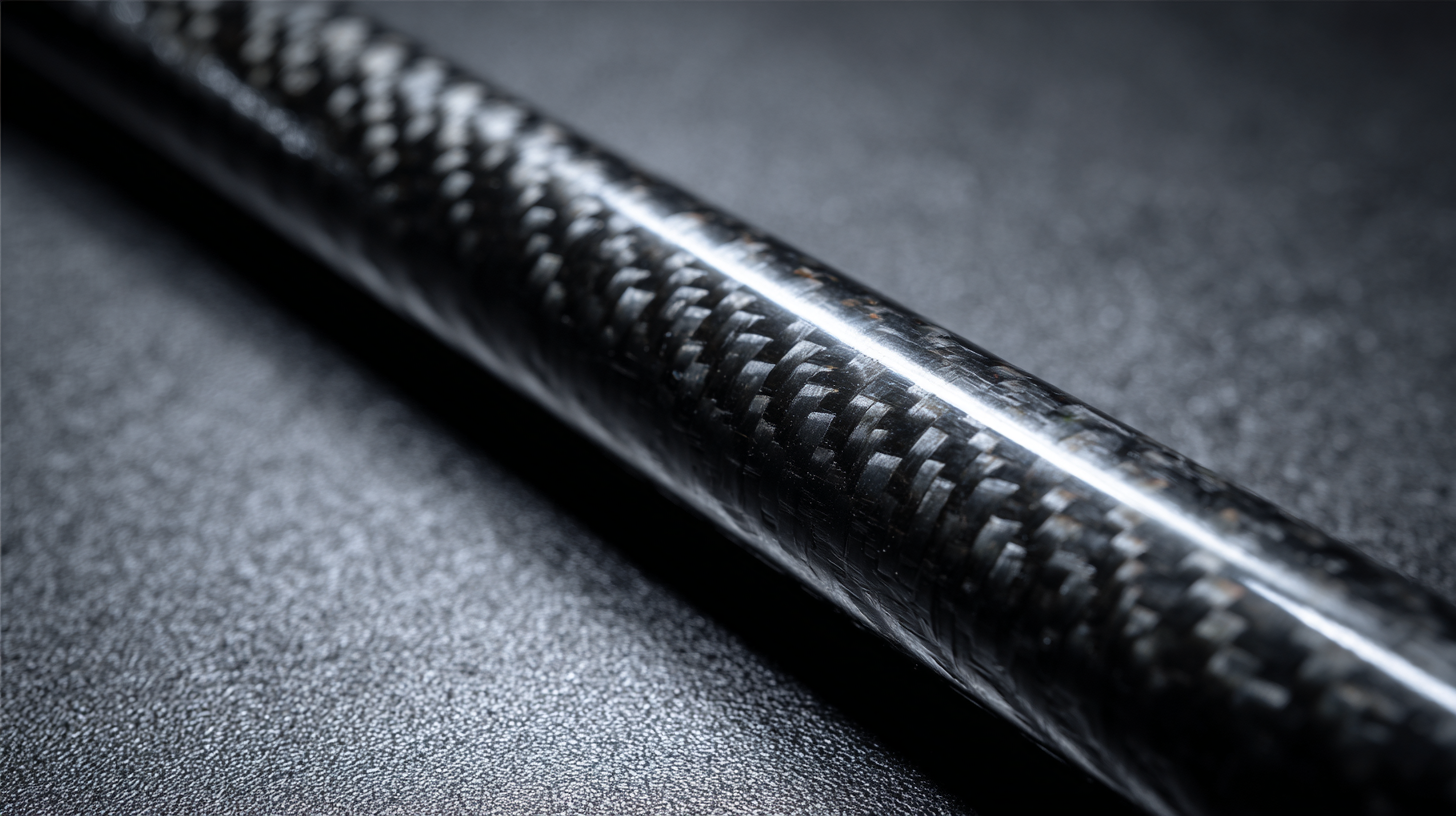

When considering pultruded carbon fiber bars, it is crucial to delve into their key technical specifications to understand their performance and suitability for various applications. Pultruded carbon fiber bars are renowned for their high strength-to-weight ratio, with tensile strengths often exceeding 1,000 MPa, which significantly surpasses traditional materials like steel. According to a report by MarketsandMarkets, the global carbon fiber market is expected to reach USD 5.73 billion by 2023, driven by the increasing demand for lightweight, high-performance materials in industries such as aerospace, automotive, and construction.

Another essential aspect of pultruded carbon fiber bars is their modulus of elasticity, typically ranging from 70 to 200 GPa, making them an excellent choice for structural applications where rigidity is paramount. Additionally, these materials boast superior corrosion resistance, allowing them to maintain integrity in harsh environments. A study by the Composite Materials Handbook highlights that pultruded profiles have a weight reduction of up to 70% compared to steel, translating to significant savings in transportation and installation costs. These specifications underscore the importance of selecting the right pultruded carbon fiber bars for applications requiring high performance and durability.

This chart compares the tensile strength and density of pultruded carbon fiber bars with alternative materials such as glass fiber, steel, and aluminum. Pultruded carbon fiber stands out for its high tensile strength while maintaining a low density, making it an excellent choice for various applications.

When considering alternatives to the best pultruded carbon fiber bar, it's essential to evaluate various materials based on their advantages and disadvantages. Fiberglass, for instance, is a popular option known for its affordability and decent strength-to-weight ratio. It works well for applications that require good resistance to corrosion and impact. However, fiberglass lacks the stiffness and durability associated with carbon fiber, making it less suitable for high-performance settings.

Another alternative is aluminum, which offers excellent tensile strength and is easier to work with than carbon fiber. It is lightweight and can withstand significant loads, making it ideal for structural applications. However, aluminum can corrode over time and may require additional treatments to enhance its longevity.

In contrast, aramid fibers provide exceptional impact resistance, making them a reliable choice for applications that demand high toughness; however, they tend to be more expensive and less widely available than other options. Each material presents its unique set of properties, and understanding these differences is crucial for making informed decisions based on specific performance requirements and budget constraints.

When choosing the right carbon fiber bar for your project, it’s essential to consider several key factors that can significantly impact performance and suitability. First and foremost, the specific application of the carbon fiber bar plays a crucial role in decision-making. Different projects, whether in cycling, automotive, or aerospace, may demand varying properties such as stiffness, weight, and flexibility. Analyze the mechanical requirements of your project to determine the best characteristics for your carbon fiber bar.

Another important consideration is the manufacturing process of the carbon fiber. Pultruded options tend to offer exceptional dimensional stability and strength-to-weight ratios, but alternatives like molded or woven carbon fiber might be more appropriate for certain applications. Additionally, think about the environmental conditions your project will face, as this can influence the durability and performance of the carbon fiber over time. Evaluating these aspects will not only help you select the most suitable carbon fiber bar but also ensure that it meets the specific needs of your project effectively.

Pultruded carbon fiber bars are increasingly finding applications across various industries due to their exceptional strength-to-weight ratio, corrosion resistance, and versatility. In aerospace, for instance, these bars are utilized in the construction of lightweight structures that enhance fuel efficiency and performance during flight. As hypersonic vehicle technology advances, the need for robust thermal protection materials becomes critical, making pultruded carbon fibers a key component in developing systems capable of withstanding extreme environmental conditions.

In the defense sector, fiber-reinforced polymer (FRP) composites are gaining traction for their superior mechanical properties. These materials are essential in the design of protective gear, vehicle components, and various structures that require high durability without adding significant weight. The integration of FRP composites allows for innovations that improve operational capabilities while ensuring the safety and effectiveness of defense personnel. As industries continue to explore alternative materials, the unique advantages of pultruded carbon fiber bars and FRP composites position them as ideal solutions for future applications.

| Application Area | Primary Benefits | Typical Uses | Material Properties |

|---|---|---|---|

| Aerospace | High strength-to-weight ratio, corrosion resistance | Structural components, interior fittings | Modulus of Elasticity: 230 GPa, Density: 1.6 g/cm³ |

| Construction | Durability, lightweight, ease of handling | Reinforcement of beams, formwork systems | Compressive Strength: 350 MPa, Tensile Strength: 500 MPa |

| Automotive | Weight reduction, improved fuel efficiency | Body panels, structural parts | Thermal Conductivity: 0.5 W/m·K, Flexural Strength: 350 MPa |

| Sporting Goods | Enhanced performance, shock absorption | Fishing rods, bicycle frames | Elastic Modulus: 70 GPa, Fatigue Strength: 150 MPa |

| Electronics | Lightweight, thermal stability | Casings, support structures | Electrical Conductivity: 10 S/m, Coefficient of Thermal Expansion: 0.005/°C |

When it comes to carbon fiber products, proper maintenance is crucial to extend their lifespan and maintain performance. According to a report by the Composites Manufacturing Association, untreated carbon fiber can show signs of degradation after just a few years, especially when exposed to harsh environmental conditions. To combat this, regular inspections and cleaning are recommended. Utilize mild soaps and water for cleaning, avoiding abrasive materials that could scratch the surface.

Additionally, the strategic storage of carbon fiber products can significantly enhance durability. A study published in the Journal of Composite Materials emphasizes that direct exposure to UV light can lead to degradation in up to 30% of the product’s strength over time. Therefore, storing these items in a cool, dry place, away from direct sunlight, can help maintain their structural integrity.

By incorporating these maintenance tips, users can ensure their pultruded carbon fiber bars and other products remain effective and resilient for years to come.