-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

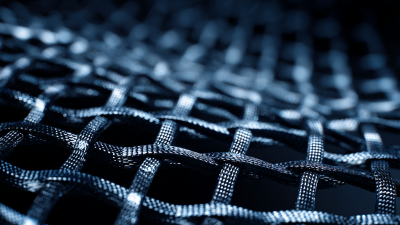

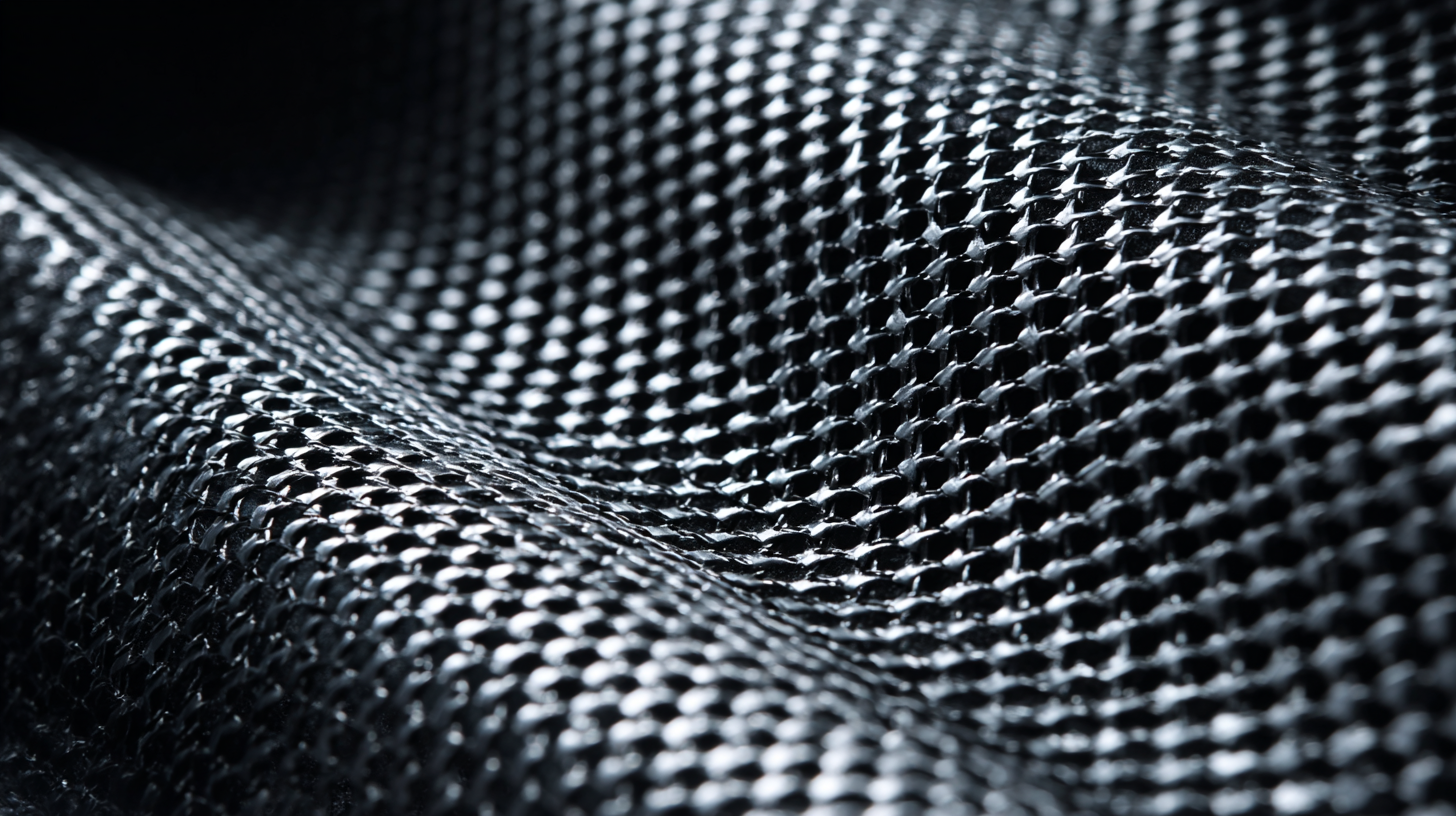

Carbon Fibre Mesh has emerged as a game-changing material in various industries, renowned for its lightweight yet robust characteristics. According to the MarketsandMarkets report, the global carbon fiber market is projected to reach $5.61 billion by 2024, driven largely by its applications in aerospace, automotive, and construction sectors. As more professionals integrate Carbon Fibre Mesh into their projects, understanding its unique properties and optimal handling techniques becomes crucial.

This versatile material not only enhances structural integrity but also contributes to energy efficiency and sustainability. However, working with Carbon Fibre Mesh requires specialized knowledge to navigate its complexities effectively. This article presents 15 essential tips for harnessing the full potential of Carbon Fibre Mesh in your projects, ensuring you achieve superior performance and durability while maximizing the benefits of this innovative material.

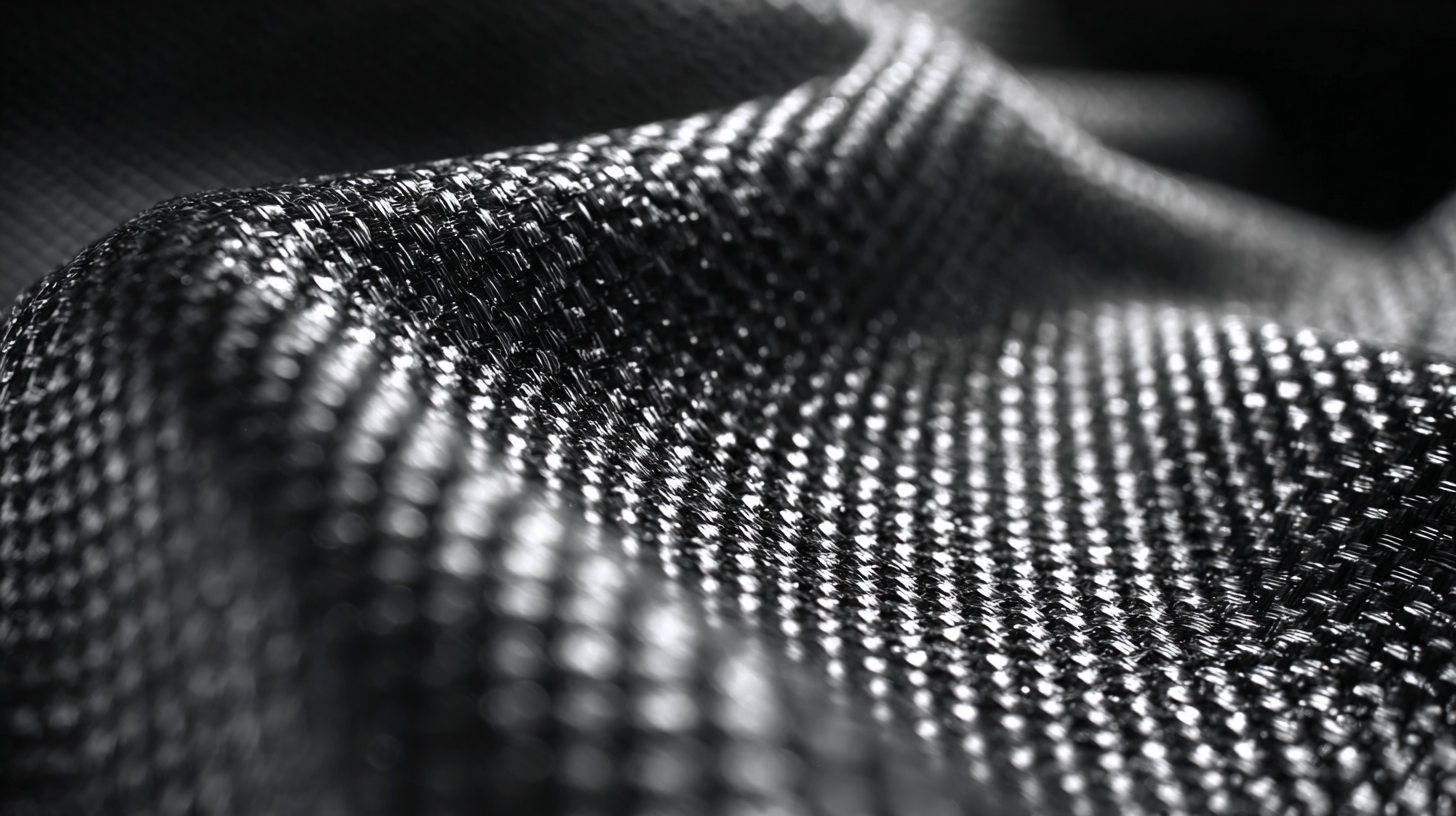

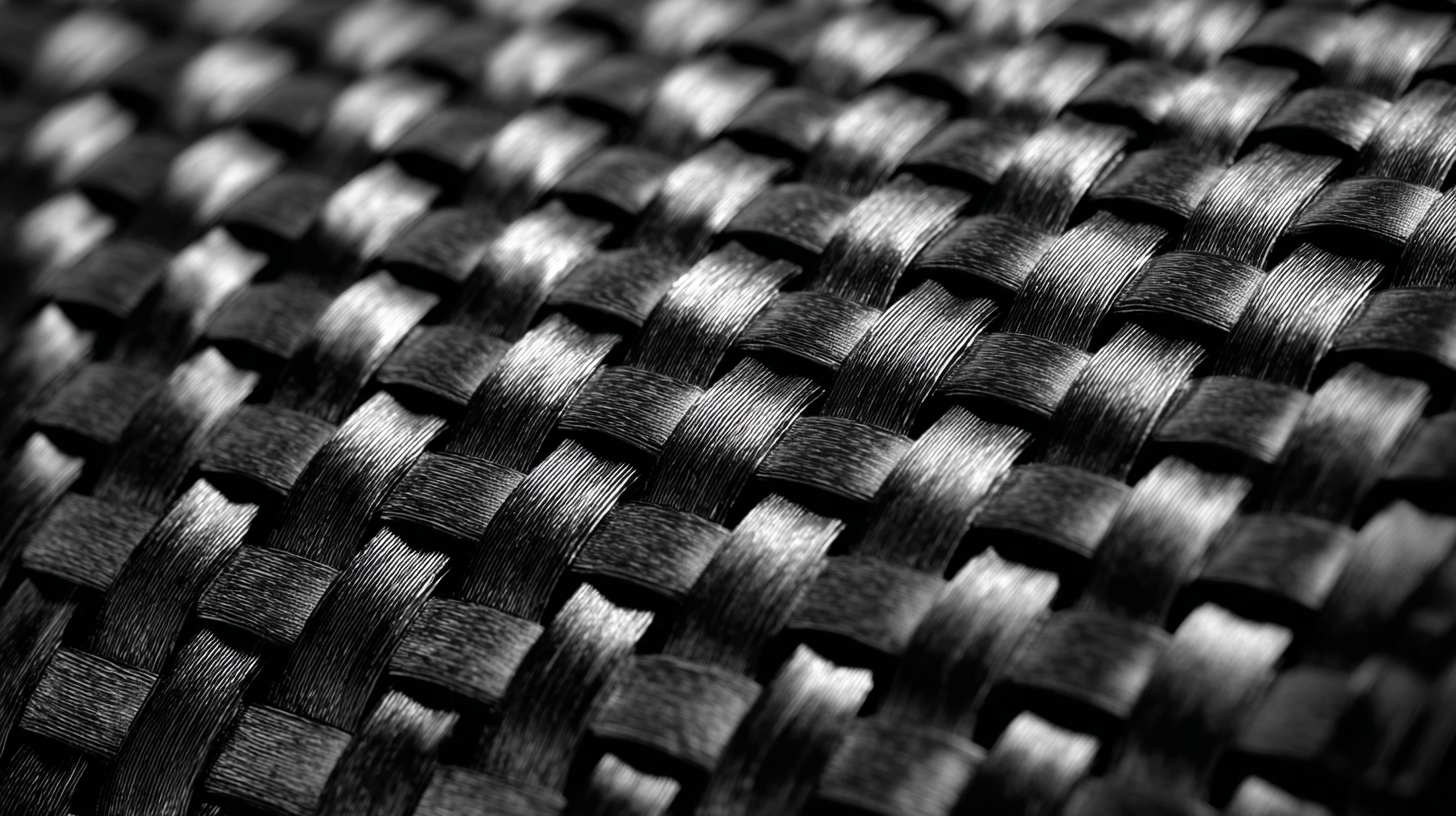

Carbon fibre mesh has gained significant attention in various industries due to its lightweight yet robust properties. Understanding the inherent characteristics of carbon fibre mesh is essential for optimal use in projects. According to a report by the Composites Market Research, carbon fibre composites are projected to grow at a CAGR of 10.6% from 2022 to 2028. This growth is driven by the material's exceptional tensile strength, which reaches up to 600 MPa, making it ideal for applications that demand both durability and weight savings.

The mesh structure of carbon fibre allows for enhanced flexibility and strength distribution, which is crucial in applications ranging from aerospace to marine engineering. A comparative analysis featured in the International Journal of Advanced Manufacturing Technology highlighted that carbon fibre mesh not only outperforms traditional materials like fiberglass in terms of strength-to-weight ratios but also exhibits superior fatigue resistance, making it a preferred choice for demanding environments. By mastering these properties, engineers and designers can leverage carbon fibre mesh to create innovative solutions that push the boundaries of design and functionality.

When working with carbon fibre mesh, having the right tools and equipment is crucial for ensuring a successful project outcome. One of the most essential tools is a high-quality cutting tool specifically designed for composite materials. According to a report by Composites World, the precision of cuts impacts the structural integrity of the final product, making the choice of a sharp, durable blade vital. A rotary cutter or a specialized composite saw can enhance efficiency and accuracy, reducing waste and improving overall project timelines.

In addition to cutting tools, protective gear is critical when handling carbon fibre mesh. Dust masks and goggles are necessary to protect against fine particles and potential inhalation risks associated with cutting or sanding carbon fibre. The Occupational Safety and Health Administration (OSHA) emphasizes the importance of personal protective equipment (PPE), especially when working in high-dust environments.

Furthermore, a pristine workspace equipped with a vacuum system can significantly mitigate dust exposure and maintain a clean work area, facilitating better project conditions and enhancing safety. Investing in these essential tools not only ensures compliance with safety regulations but also improves the quality and longevity of the projects involving carbon fibre mesh.

When working with carbon fibre mesh, effective cutting and shaping techniques are crucial to ensure optimal performance in various applications. First and foremost, it is advisable to use specialized tools designed for composite materials. Diamond-coated blades or carbide-tipped cutters should be preferred because they can handle the toughness of carbon fibre without causing fraying or unwanted damage. Additionally, it is beneficial to cut the mesh in a well-ventilated area while wearing appropriate safety gear, as cutting can release fine particles that are harmful when inhaled.

Once cut, shaping carbon fibre mesh to fit specific project requirements necessitates careful handling. Employing a vacuum bagging technique can help maintain the integrity of the shape during the curing process, which is particularly important in applications such as aerospace and automotive industries. The application of heat can also assist in shaping; however, it should be done cautiously to prevent overstressing the material. Utilizing precise molds can provide further consistency in the final product. With these techniques in place, projects can leverage the lightweight strength and corrosion resistance of carbon fibre mesh, ultimately enhancing performance across various sectors.

When working with carbon fibre mesh, applying adhesives properly is crucial to ensure the structural integrity and longevity of your projects. According to a report by Composites World, improper adhesive application can lead to a bond strength reduction of up to 50%. To avoid this, it is essential to follow best practices, including surface preparation, adhesive selection, and application techniques. Ensure that the surfaces are cleaned thoroughly to remove any contaminants, as even microscopic debris can compromise the bond.

Additionally, choosing the right adhesive is vital. Epoxy resins are often recommended for bonding carbon fibre materials due to their excellent strength and durability. Data from the Adhesive and Sealant Council indicates that epoxy adhesives can achieve shear strength values exceeding 30 MPa when applied correctly. It is important to apply an even layer of adhesive and consider the environmental conditions during curing, as temperature and humidity can significantly affect the final bond strength. Utilizing clamps or weights during the curing process can also help in achieving optimal adhesion and preventing any shifts that could weaken the bond.

When working with carbon fibre mesh, achieving a perfect finish is crucial for both aesthetics and durability. One effective technique is the application of a high-quality epoxy resin, which not only enhances the visual appeal but also significantly improves the mesh's resistance to environmental degradation. According to a 2021 report by the Composites World, properly finished carbon fibre composites can exhibit a tensile strength increase of up to 30%, making it essential to master these finishing techniques.

Additionally, incorporating a UV-resistant topcoat can safeguard the mesh from harmful sun exposure, prolonging its lifespan. This is especially important for projects used in outdoor settings. The American Composites Manufacturers Association (ACMA) stated that products treated with UV coatings can maintain their aesthetic qualities for over five years, compared to untreated composites that may fade or deteriorate within just a year.

When applying finishing techniques, ensure to follow these tips: always clean the surface before application to eliminate contaminants that could interfere with adhesion, and use thin, even layers of resin or coatings to prevent pooling or bubbles that could mar the final look. Also, curing the material in a controlled environment can lead to superior results, enhancing both structural integrity and finishing quality in carbon fibre mesh applications.

This chart illustrates the tensile strength of different carbon fibre mesh types, showcasing the variations that can affect durability and aesthetics in applications. Choosing the right type for your project is essential for achieving optimal performance.