-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

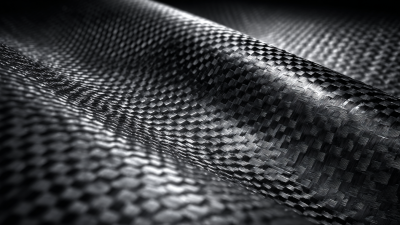

In recent years, the demand for advanced materials in various industries has surged, with the flexible carbon fiber sheets leading the charge due to their exceptional strength-to-weight ratio and adaptability. According to a report by MarketsandMarkets, the global carbon fiber market is projected to reach $5.74 billion by 2025, driven by the increasing adoption of lightweight materials in automotive and aerospace applications. Flexible carbon fiber sheets are particularly valued for their versatility, allowing for innovative designs and efficient manufacturing processes.

Whether you’re an engineer, designer, or DIY enthusiast, understanding the nuances of working with these materials is essential. This blog will provide you with 15 essential tips for effectively utilizing flexible carbon fiber sheets in your projects, ensuring you can maximize their potential while minimizing common pitfalls.

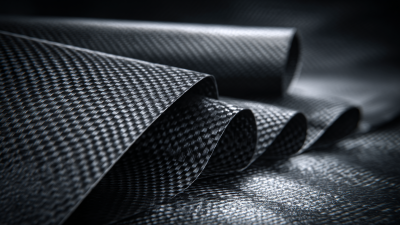

When embarking on a project that incorporates flexible carbon fiber sheets, selecting the appropriate thickness is crucial for achieving the desired strength and flexibility. Carbon fiber sheets are available in various thicknesses, typically ranging from 0.5 mm to 3 mm. A thinner sheet may offer greater flexibility, making it ideal for applications requiring intricate bending or shaping, such as in the design of curved surfaces or lightweight components. Conversely, thicker sheets provide enhanced rigidity and durability, which may be necessary for structural applications or where enhanced load-bearing capacity is required.

Understanding the specific demands of your project is essential when choosing the right thickness. For example, if the project involves dynamic movement or frequent flexing, opting for a thinner sheet will generally yield better performance. However, if the goal is to create a robust framework or support system, a thicker sheet will be more advantageous. It’s also important to consider how the thickness will affect the overall weight of your final product. Balancing strength, flexibility, and weight will help ensure that your project not only functions optimally but also meets any aesthetic or design requirements you may have.

Flexible carbon fiber sheets have rapidly gained popularity across various industries due to their unique combination of lightweight properties and exceptional strength. According to a report by MarketsandMarkets, the carbon fiber composites market is projected to reach $6.5 billion by 2025, highlighting the growing reliance on advanced materials like flexible carbon fiber in sectors such as aerospace, automotive, and sporting goods. The versatility of these sheets makes them ideal for applications requiring durability without adding excessive weight, making them a preferred choice for manufacturers and DIY enthusiasts alike.

When working with flexible carbon fiber sheets, it is essential to consider specific tips for optimal utilization. First, always ensure that you use proper cutting tools, such as a carbon fiber cutter or a diamond saw blade, to avoid fraying the edges. Additionally, pay attention to the adhesives used; a high-performance epoxy resin is recommended to ensure a strong bond when assembling carbon fiber components. Furthermore, remember that while flexible, these sheets require careful handling during bending or shaping to maintain their structural integrity.

Embracing the advantages of lightweight yet robust flexible carbon fiber sheets will undoubtedly enhance the efficiency and performance of your projects. By following best practices and leveraging the material's strengths, you can achieve remarkable results that meet modern demands in various applications.

When working with flexible carbon fiber sheets, having the right tools and techniques is essential for safe and effective cutting. One of the most crucial tools is a sharp utility knife or specialized blade designed for composites. These tools help achieve cleaner cuts, which are vital for maintaining the material's integrity. Additionally, using a cutting mat can protect surfaces and prolong the life of your blades. Always ensure you're wearing suitable personal protective equipment (PPE), such as goggles and masks, to guard against dust and splinters that may arise during the cutting process.

Techniques like scoring the material prior to cutting can be highly effective. This method reduces stress on the fibers and minimizes chipping. Furthermore, taking advantage of clamps to secure the sheets can prevent movement, providing better control during the cutting phase. With the recent advances in composite materials across various industries, including automotive and aerospace, understanding these fundamental methods is more important than ever. As the demand for innovative applications continues to rise, so does the importance of mastering these essential tools and techniques for working safely and effectively with carbon fiber sheets.

When working with flexible carbon fiber sheets, effective bonding and joining techniques are crucial for achieving optimal results in your projects. One of the most important tips to consider is the surface preparation of the carbon fiber itself. Ensure that the surfaces are clean, dry, and free from contaminants like dust, oils, or old adhesives. Using isopropyl alcohol for cleaning can significantly enhance the bonding surface, allowing adhesives to form a stronger connection.

Another effective method for bonding carbon fiber sheets is through the use of specialized adhesives designed for composite materials. Epoxy adhesives are particularly popular because they provide a robust bond and can fill gaps between uneven surfaces. Applying the adhesive evenly and allowing adequate curing time is key to ensuring the reliability and strength of the bond. For mechanical joining, consider using rivets or screws specifically designed for carbon fiber, which can help distribute stress evenly across the sheet and reduce the risk of delamination. Each technique you choose should be tailored to the specific needs of your project to promote longevity and structural integrity.

| Tip Number | Tip Description | Recommended Tools | Bonding Method |

|---|---|---|---|

| 1 | Ensure clean surfaces before application. | Acetone, lint-free cloth | Epoxy Adhesive |

| 2 | Choose the right adhesive for your project. | Various adhesives | Cyanoacrylate, Epoxy |

| 3 | Use clamps to hold sheets during curing. | Clamps | Mechanical Fastening |

| 4 | Consider temperature and humidity for bonding. | Thermometer, Hygrometer | Heat Cure Adhesives |

| 5 | Use vacuum bagging for a strong bond. | Vacuum pump, Bagging film | Epoxy Resins |

| 6 | Allow adequate cure time for adhesives. | Timer | Not Applicable |

| 7 | Roughen surfaces for better adhesion. | Sandpaper | Mechanical Bonds |

| 8 | Test adhesive on scrap material. | Sample pieces | Not Applicable |

| 9 | Ensure proper alignment before bonding. | Alignment tools | Screws or Dowels |

| 10 | Innovate with layering techniques. | Layering supplies | Epoxies, Primers |

| 11 | Use jigs to maintain shape during curing. | Jigs | Not Applicable |

| 12 | Keep workspace organized for efficiency. | Storage containers | Not Applicable |

| 13 | Wear safety gear during cutting and bonding. | Safety glasses, gloves | Not Applicable |

| 14 | Choose lightweight sheets for complex projects. | Material sources | Not Applicable |

| 15 | Document your process for future reference. | Notebook, camera | Not Applicable |

When working with flexible carbon fiber sheets, finishing touches are critical to ensuring durability and aesthetic appeal. The right coating can enhance the surface while protecting against environmental stressors. A popular option is applying a clear epoxy resin, which not only provides a glossy finish but also adds a strong layer of protection against UV rays, moisture, and scratches. This coating method ensures that your carbon fiber projects maintain their sleeker appearance over time while reinforcing their structural integrity.

When working with flexible carbon fiber sheets, finishing touches are critical to ensuring durability and aesthetic appeal. The right coating can enhance the surface while protecting against environmental stressors. A popular option is applying a clear epoxy resin, which not only provides a glossy finish but also adds a strong layer of protection against UV rays, moisture, and scratches. This coating method ensures that your carbon fiber projects maintain their sleeker appearance over time while reinforcing their structural integrity.

For additional protection, consider using specialized carbon fiber coatings or sealants that are designed to withstand the rigors associated with frequent use. These products can help to prevent fading and degradation due to exposure to elements, making them ideal for outdoor applications. Before applying any finish, it's essential to properly clean and prepare the surface of the carbon fiber sheets to ensure optimal adhesion. This attention to detail will result in a polished look and extended lifespan for your projects, allowing you to enjoy the full benefits of carbon fiber technology.