-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

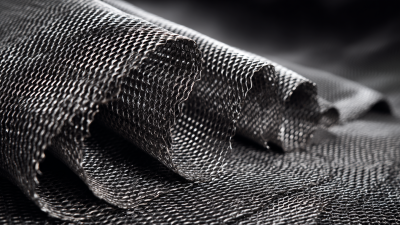

In the ever-evolving landscape of industrial applications, the choice of materials plays a critical role in enhancing efficiency and performance. Among the myriad options available, Carbon Fiber Rope has emerged as a game-changer, offering unparalleled strength and versatility. Not only is it significantly lighter than traditional alternatives, but its remarkable tensile strength makes it ideal for demanding environments. This blog delves into the seven essential benefits of using Carbon Fiber Rope in various industrial settings, showcasing how its unique properties can lead to greater operational effectiveness, improved safety, and cost efficiency.

Whether you're in construction, manufacturing, or any other field requiring durable solutions, understanding the advantages of Carbon Fiber Rope can help you make informed decisions that propel your projects forward.

Carbon fiber rope has emerged as a revolutionary material in various industrial applications, thanks to its unique properties and advantages. Known for its remarkable strength-to-weight ratio, carbon fiber rope offers exceptional tensile strength while remaining lightweight. This makes it an ideal choice for industries that require durable and portable solutions, such as aerospace and marine engineering. In addition, carbon fiber is resistant to corrosion and UV radiation, enhancing its longevity in harsh environments.

When incorporating carbon fiber rope into your projects, consider the following tips: first, always assess the specific load requirements and environmental factors to select the appropriate diameter and type of rope. Second, ensure that all connections and terminations are compatible with the carbon fiber material to minimize wear and maintain integrity. Finally, regular inspection and maintenance can help identify potential issues before they arise, ensuring a safer and more efficient application.

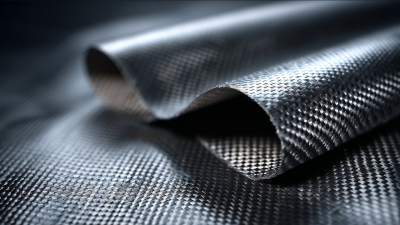

Moreover, carbon fiber rope exhibits minimal stretch, making it an excellent option for applications that require precision and stability. Its unique properties not only enhance performance but also contribute to cost-effectiveness over time due to reduced downtime and maintenance needs. By leveraging these advantages, industries can significantly improve their operational efficiency and safety standards.

Carbon fiber rope is revolutionizing industrial applications with its enhanced durability, surpassing traditional materials in various critical metrics. Studies indicate that carbon fiber composites exhibit tensile strengths exceeding 600 MPa, making them more resilient under stress compared to conventional materials such as nylon or polyamide, which often struggle under similar conditions. This exceptional strength-to-weight ratio allows for lighter, stronger solutions in industries like construction and marine, where reducing weight while maintaining robust performance is paramount.

Recent advancements also highlight the potential of integrating recycled materials in the production of carbon fiber ropes. The innovative use of recycled polyamide 6, derived from fishing nets, demonstrates a commitment to sustainability within the industry, offering an alternative that minimizes waste and promotes eco-friendly practices. As reported, these sustainable composites not only maintain high mechanical performance but also contribute to a lower life cycle analysis (LCA), emphasizing the value of choosing carbon fiber over traditional options for both environmental and operational efficiency. This synergy of durability and sustainability positions carbon fiber rope as a superior choice for future industrial applications.

Carbon fiber rope is rapidly gaining traction in industrial applications, chiefly due to its remarkable weight benefits. The lightweight nature of carbon fiber significantly reduces operational loads in various sectors, from deepwater projects to offshore drilling. Unlike traditional steel cables that can be cumbersome and heavy, carbon fiber rope can dramatically minimize the weight being hoisted or transported, ultimately leading to enhanced operational efficiency. The global synthetic rope market is projected to grow from approximately USD 1.77 billion in 2025 to USD 3.04 billion by 2033, reflecting a CAGR of 7.04%. This trend indicates a robust demand for lightweight materials in industrial applications.

Moreover, when replacing steel with composite materials like carbon fiber, industries can achieve not only weight savings but also improved economic viability for complex projects, such as oil and gas development. By reducing the weight of the rope, businesses can decrease fuel costs and enhance equipment lifespan, as lighter loads exert less strain on machinery.

Tip: When selecting ropes for industrial applications, consider the weight-to-strength ratio that carbon fiber offers. It's crucial to evaluate the specific lifting requirements and ensure compliance with safety standards.

Tip: Ensure routine inspections of carbon fiber ropes to maintain optimal performance. Regular maintenance can identify wear and tear, further extending the longevity of your equipment in demanding environments.

Carbon fiber rope has emerged as a game-changer across various industrial applications, thanks to its remarkable versatility and superior properties. Industries such as aerospace, automotive, and marine have increasingly adopted this innovative material due to its incredible strength-to-weight ratio and resistance to environmental factors. In aerospace, carbon fiber rope is used in lifting and securing components, ensuring safety while minimizing weight. Similarly, in the automotive sector, its application in securing lightweight structures allows for better fuel efficiency and performance enhancements.

Moreover, the marine industry benefits significantly from carbon fiber rope, which boasts excellent resistance to saltwater and UV degradation. This makes it ideal for mooring lines and rigging, providing both reliability and longevity in challenging environments. Additionally, carbon fiber rope can be customized to suit specific needs, making it incredibly adaptable for other applications such as construction and telecommunications. Its lightweight properties and strength allow for high-tension applications without adding unnecessary bulk, facilitating easier handling and installation. As industries continue to seek materials that can enhance performance while reducing weight, carbon fiber rope stands out as an indispensable asset across diverse sectors.

This chart illustrates the versatility of carbon fiber rope across various industries by showcasing the percentage of usage in different applications.

In industrial applications, the choice of material can significantly influence both operational effectiveness and long-term financial viability. Carbon fiber rope stands out as a prime candidate, particularly due to its cost efficiency. Although the initial investment in carbon fiber may be higher than traditional materials, its remarkable durability and low maintenance requirements lead to substantial savings over time. Industries that incorporate carbon fiber rope can expect to see reduced replacement costs, minimizing downtime and enhancing productivity.

Moreover, carbon fiber’s lightweight properties contribute to decreased transportation and handling costs. This material allows for easier maneuverability and installation, which in turn lowers labor expenses and increases safety on work sites. In environments where performance and reliability are paramount, the long-lasting nature of carbon fiber rope ensures that companies can allocate their budgets more effectively, focusing on innovation and growth rather than constantly repairing or replacing worn-out equipment. Overall, integrating carbon fiber rope not only streamlines operational processes but also delivers significant long-term financial benefits.

| Benefit | Description | Cost Savings (Estimated %) | Durability (Years) |

|---|---|---|---|

| Lightweight | Significantly reduces transport costs and labor intensity. | 20% | 15 |

| High Strength | Designed for high load-bearing applications, minimizing material failure. | 25% | 30 |

| Corrosion Resistance | Ideal for harsh environments where traditional materials may fail. | 30% | 20 |

| Elasticity | Provides flexibility in application without compromising strength. | 15% | 10 |

| Reduced Maintenance | Lower frequency of replacements and repairs. | 40% | 25 |

| Thermal Stability | Performs effectively in extreme temperature conditions. | 10% | 20 |

| Versatility | Applicable in various industries including marine, construction, and aerospace. | 20% | 15 |