-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Cut Proof Fabric is revolutionizing various industries by providing essential protection against sharp objects. In recent years, the demand for cut-resistant materials has surged, particularly in sectors like manufacturing, healthcare, and outdoor activities. A report by MarketsandMarkets indicates that the global cut-resistant gloves market is projected to reach USD 4.25 billion by 2026. This highlights a growing awareness of safety measures in workplaces where risks are prevalent.

In 2026, Cut Proof Fabric will likely see broader applications, expanding beyond gloves. Its use in clothing and gear is gaining traction among outdoor enthusiasts and industrial workers alike. As consumers become more safety-conscious, the emphasis on quality and compliance with safety standards increases. Yet, there remains a challenge in balancing cost with performance. Not all fabrics labeled as cut-proof meet rigorous testing requirements, leading to confusion and potential safety risks.

Continued innovation is essential in the development of Cut Proof Fabric. While many companies invest in research, true advancements must prioritize both durability and comfort. This balance is not easily achieved. It prompts a reflection on industry standards and the shared responsibility to ensure consumer safety. As we look to the future, the effectiveness and reliability of Cut Proof Fabric will remain critical for its sustainability and acceptance in diverse applications.

Cut proof fabric is a specialized material designed to resist cuts and abrasions. Made from high-performance fibers, it offers enhanced durability. This fabric is often used in protective gear, like gloves and clothing. Its unique composition allows it to withstand sharp objects. The fibers are tightly woven, creating a barrier against potential hazards.

One notable characteristic of cut proof fabric is its lightweight nature. Users can enjoy protection without feeling weighed down. This makes it ideal for various industries. Healthcare workers benefit significantly from such materials. They require reliable protection when handling sharp instruments. Similarly, workers in construction and manufacturing face similar risks. Here, the fabric plays a vital role in preventing injuries.

However, not all cut proof fabrics are created equal. Some may lack flexibility or breathability. This could impact comfort during prolonged use. It’s essential to consider these factors when choosing the right fabric. The balance between protection and usability is crucial. Optimizing this balance can lead to better safety measures in the workplace or other environments.

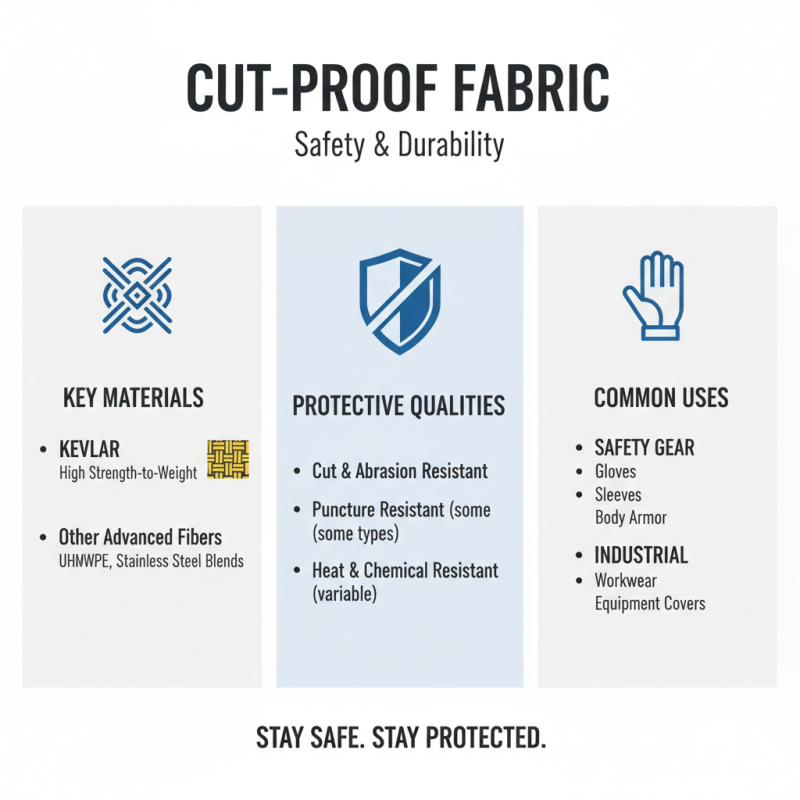

Cut proof fabric is designed for safety and durability. Various materials contribute to its protective qualities. One common material is Kevlar, known for its high strength-to-weight ratio. It’s often used in gloves and sleeves to prevent cuts and abrasions.

Another popular material is Dyneema. It is lightweight yet incredibly strong. This fabric is often found in personal protective equipment and industrial applications. Many industries rely on it for safety gear. Both materials provide excellent protection while allowing for mobility.

Tips: When choosing cut proof fabric, consider the environment. Different jobs have varying risks. Evaluate the type of protection needed for specific tasks. Additionally, always conduct regular inspections of the fabric. Look for any signs of wear or damage. This can help ensure ongoing safety. Understanding the properties of each material helps in making informed decisions.

The rise of cut proof fabric is reshaping multiple industries in 2026. This material offers enhanced protection against sharp objects. Construction and manufacturing sectors are early adopters. Workers face hazards daily. Cut proof fabrics reduce injuries significantly, increasing safety and productivity.

Healthcare is another area benefiting from this innovation. Medical staff often encounter sharp tools and devices. Wearable cut proof gear ensures their safety. It allows professionals to focus more on patient care. Food processing industries also utilize this fabric. Workers handle knives and slicers frequently. Protective clothing keeps them safe from accidents.

The agricultural sector is exploring cut proof fabrics too. Farmers use sharp tools in the field. Cut resistant gloves and aprons are becoming essential. This fabric is also being tested in recreational gear. Campers and outdoor enthusiasts seek added protection. The market is evolving rapidly. Companies need to assess their needs carefully. Balancing safety and functionality is crucial.

Cut proof fabrics are becoming essential in various industries by 2026. These materials are designed to resist cuts and abrasions effectively. Innovations in technology are continuously enhancing their performance. For instance, studies show that high-performance fibers, like ultra-high-molecular-weight polyethylene, significantly improve cut resistance compared to traditional fabrics.

In the healthcare sector, cut proof fabrics are crucial for ensuring safety. Medical personnel utilize them to protect against sharp instruments while performing surgeries. They can also prevent injuries in emergency response settings, where rapid actions often lead to risks. Data from industry reports suggest that the demand for cut-resistant wear in healthcare will increase by over 30% by 2026.

Tips: When choosing cut proof fabric, consider weight and flexibility. Lighter fabrics offer comfort, while flexibility enhances movement. Always check the latest test results to ensure the level of protection meets your needs. Additionally, remember that maintenance matters. Regular washing and careful handling can extend the lifespan of cut proof textiles.

As we look towards 2026, the evolution of cut-proof fabric is truly fascinating. Designers are integrating advanced fibers that enhance protection without sacrificing comfort. Imagine breathable materials that offer both flexibility and resistance. These fabrics are becoming essential in various industries like healthcare and manufacturing.

Innovative designs are also emerging. Mix-and-match styles are more common now. Users want to feel safe but also stylish. Some fabrics may even include smart technology, alerting wearers to potential hazards. While exciting, these developments raise questions about durability and maintenance. How will these fabrics stand the test of time?

Sustainability is another vital consideration for future cut-proof materials. The demand for eco-friendly options is rising. However, achieving this while maintaining high performance poses challenges. Research is ongoing, and the path is not always clear. The balance between protection and sustainability requires constant reflection and improvement.