-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In the world of engineering and design, selecting the right materials can make or break a project’s success, and this is especially true when it comes to the use of Carbon Fiber Tubes. Known for their exceptional strength-to-weight ratio and versatility, Carbon Fiber Tubes are increasingly favored across various industries, from aerospace to sports equipment. However, with a plethora of options available, making an informed choice can be daunting.

This ultimate guide aims to simplify the selection process, offering solutions tailored to your specific project requirements. Whether you are crafting a high-performance bicycle frame or designing an advanced structural component, understanding the characteristics and applications of Carbon Fiber Tubes will empower you to make the best decision for your needs. Join us as we delve into the various factors to consider and discover the ideal Carbon Fiber Tube for your next innovative endeavor.

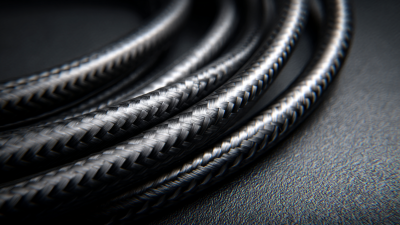

When selecting materials for engineering projects, carbon fiber tubes often emerge as an excellent choice due to their unique benefits across various applications. One of the standout properties of carbon fiber is its exceptional strength-to-weight ratio. This makes it ideal for aerospace, automotive, and sporting goods industries, where reducing weight without compromising strength is crucial. For instance, in race cars, carbon fiber tubes enhance performance while ensuring safety, as they can withstand high impact without adding significant mass.

Another compelling advantage of carbon fiber tubes is their resistance to corrosion and fatigue. Unlike traditional materials like aluminum or steel, carbon fiber does not rust or degrade when exposed to harsh environmental conditions. This characteristic extends the lifespan of products that utilize these tubes, making them an economical choice in the long run. Additionally, the versatility of carbon fiber allows it to be custom-manufactured to meet specific dimensions or shapes, catering to the unique needs of various projects. Whether you are creating a lightweight bicycle frame or a durable industrial component, carbon fiber tubes provide innovative solutions that set your project apart.

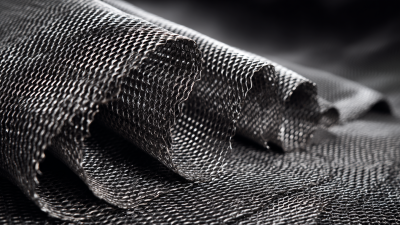

When selecting a carbon fiber tube for your project, understanding the types of carbon fiber available is crucial to achieving optimal performance. There are primarily two categories of carbon fiber: standard and specialty grades. Standard carbon fiber is often utilized in applications requiring a good balance between strength and weight, making it suitable for industries like automotive and aerospace. According to the Composite Materials Handbook, standard carbon fiber composites can achieve tensile strengths of up to 600 MPa while remaining lightweight, with a density as low as 1.59 g/cm³.

In contrast, specialty carbon fibers, such as high-modulus and ultra-high modulus variants, offer superior stiffness and strength, which is particularly beneficial for applications like aerospace components and high-performance sporting equipment. A report from the Carbon Fiber Manufacturers Association emphasizes that high-modulus fibers can have tensile moduli exceeding 400 GPa. This makes them ideal for projects where rigidity is paramount. By understanding these differences, you can select the most suitable carbon fiber type that aligns with the specific demands of your project, ensuring enhanced performance and durability.

This chart compares the tensile strength of various types of carbon fiber tubes. Different tubing options cater to specific project requirements based on their tensile properties.

When selecting the right carbon fiber tube for your project, there are several key features to consider. First and foremost, assess the tube's stiffness and strength-to-weight ratio. Carbon fiber is renowned for its lightweight nature while providing exceptional strength, making it ideal for applications where weight savings are critical. It's important to choose a tube that balances these properties effectively to meet the demands of your specific project.

Another crucial factor is the tube's diameter and wall thickness. The diameter affects the overall structure and integrity, while wall thickness influences the tube's ability to withstand external forces. Depending on your use case—whether it’s for a fishing rod or a bike frame—you'll need to determine the optimal measurements for performance and durability.

Tips: Always check for the manufacturer's specifications on the carbon fiber tube. Look for information on the material's manufacturing process as this can impact performance. Additionally, consider the environmental factors the product will face, such as UV exposure or temperature extremes, to ensure longevity and reliability.

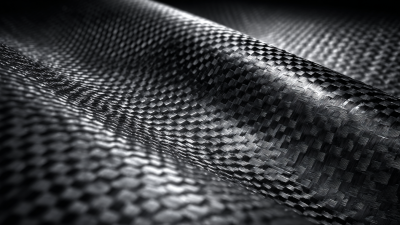

When it comes to optimizing performance in various projects,

carbon fiber tubes stand out for their exceptional

strength-to-weight ratio. These advanced materials can significantly enhance the structural

integrity of a design while simultaneously reducing its overall weight. This is particularly beneficial

in industries like aerospace, automotive, and sports equipment, where every gram matters.

By using carbon fiber tubes, engineers are able to create lighter yet more robust structures, leading to

improved efficiency and agility.

The lightweight nature of carbon fiber tubes doesn’t just bolster performance; it also opens up new

possibilities in design and functionality. For instance, in

the realm of sporting goods, athletes can experience greater maneuverability and speed

without sacrificing durability. Furthermore, the stiffness of carbon fiber materials allows for

superior performance under stress, making it an ideal choice for applications requiring both

resilience and lightweight components. Embracing carbon fiber technology in your project could lead to

significant advancements that set your work apart in a competitive landscape.

The lightweight nature of carbon fiber tubes doesn’t just bolster performance; it also opens up new

possibilities in design and functionality. For instance, in

the realm of sporting goods, athletes can experience greater maneuverability and speed

without sacrificing durability. Furthermore, the stiffness of carbon fiber materials allows for

superior performance under stress, making it an ideal choice for applications requiring both

resilience and lightweight components. Embracing carbon fiber technology in your project could lead to

significant advancements that set your work apart in a competitive landscape.

The environmental impact of carbon fiber is a growing concern as industries increasingly rely on this material for its strength and lightweight properties.

Carbon fiber reinforced polymer (CFRP) production is resource-intensive, typically involving significant energy consumption and emissions.

According to recent studies, the carbon footprint of traditional carbon fiber manufacturing ranges from 15 to 30 tons of CO2 per ton of material produced.

However, advancements in recycling technology are offering new avenues for sustainability. Current techniques are being evaluated, with an emphasis on improving the reclamation of carbon fibers from CFRP waste, potentially leading to up to 90% recovery rates.

Tips for Sustainable Carbon Fiber Use: