-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In the ever-evolving landscape of advanced materials, the choice of the right Pultruded Carbon Fiber Bar is pivotal for engineers and manufacturers seeking to optimize performance and durability in their applications. Recent market reports indicate that the carbon fiber industry is projected to reach $4.5 billion by 2025, with pultruded products gaining significant traction due to their lightweight and high-strength properties. These bars are increasingly utilized in sectors such as aerospace, automotive, and construction, where strength-to-weight ratios are critical. However, selecting the appropriate Pultruded Carbon Fiber Bar requires careful consideration of various factors including the specific application, mechanical properties, and environmental resistance. By following these five essential tips, stakeholders can ensure they make informed decisions that will enhance their projects' longevity and effectiveness, thus leveraging the full potential of carbon fiber technology.

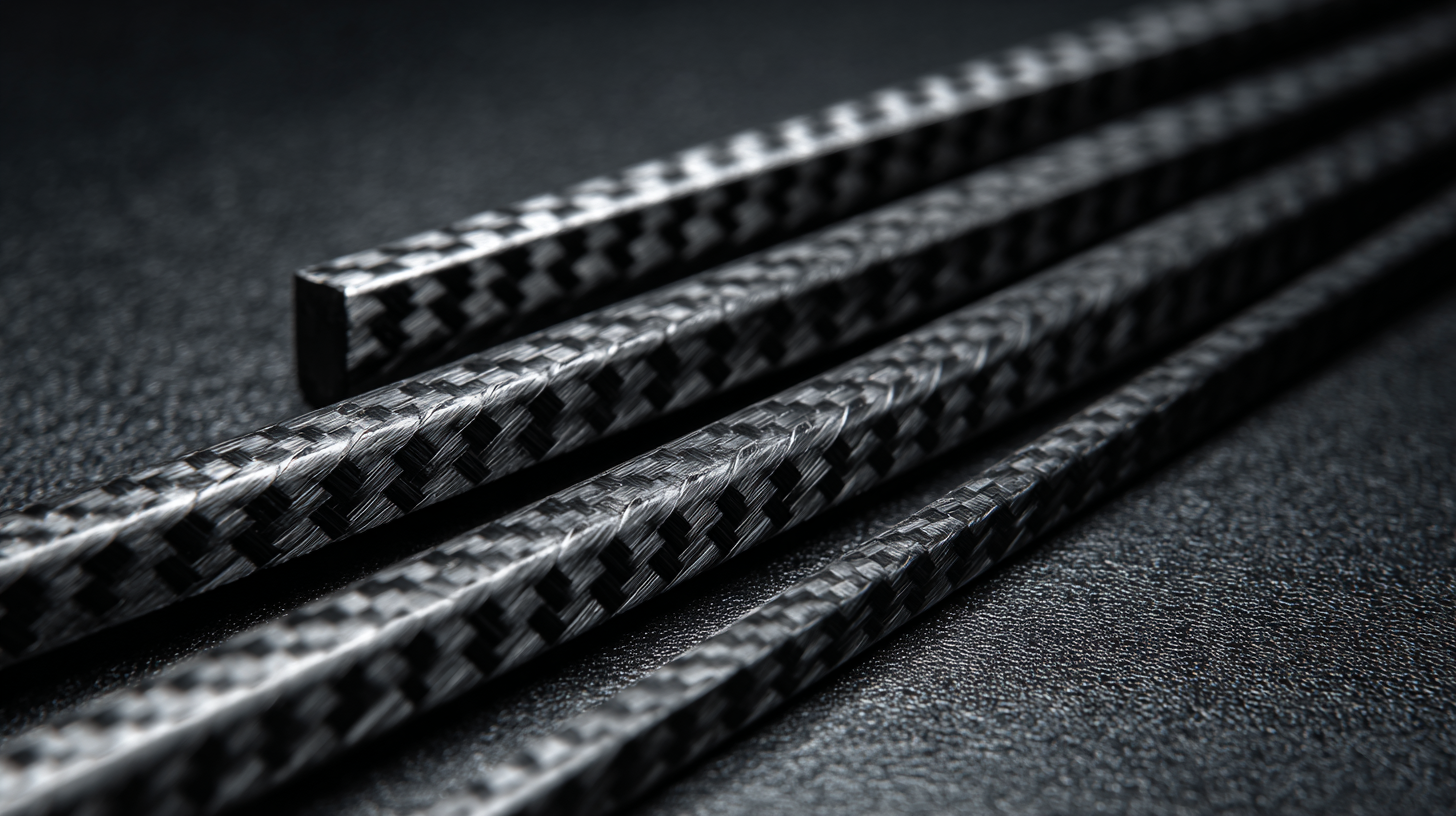

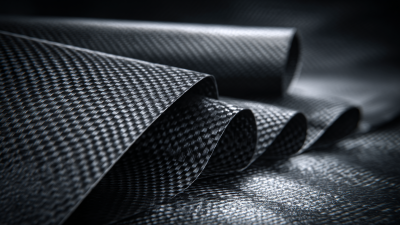

Pultruded carbon fiber is a composite material known for its exceptional strength-to-weight ratio and rigidity. This process involves the continuous pulling of fibers through a resin bath, followed by a heated die that shapes and cures the material. The resulting bars exhibit unique properties, such as excellent corrosion resistance and thermal stability, making them ideal for a wide range of applications.

Industries such as aerospace, automotive, and construction increasingly rely on pultruded carbon fiber bars for structures that require lightweight yet strong components.

One of the key advantages of pultruded carbon fiber is its ability to be customized in terms of size and shape, catering to specific design requirements. These bars can withstand significant loads while also being resistant to environmental factors such as UV radiation and moisture, ensuring longevity even in harsh conditions.

From structural support beams in skyscrapers to components in high-performance sports equipment, the versatility of pultruded carbon fiber bars is evident. Understanding these properties helps in selecting the right material for your project, ensuring optimal performance and durability.

When choosing the right pultruded carbon fiber bar, one of the most critical factors to evaluate is the strength-to-weight ratio. This metric is especially crucial in industries where performance in structures is paramount, such as aerospace, automotive, and civil engineering. A high strength-to-weight ratio not only ensures that the material can support significant loads without adding excessive weight but also enhances the overall efficiency of the structures being built.

To make an informed decision, it's important to compare different grades of carbon fiber. Each grade comes with its own unique properties that affect both strength and weight. For example, while some bars may offer superior tensile strength, they might also come with increased weight. Conducting thorough tests and examining material specifications can help you identify the best options that align with your project requirements. Additionally, consider the environmental conditions the structure will face, as these factors can also influence the performance and durability of the carbon fiber bars. Prioritizing the right balance between strength and weight will lead to optimal performance in your design, ensuring safety and longevity.

When choosing pultruded carbon fiber bars for a variety of applications, assessing their environmental resistance is crucial. Key factors such as UV exposure, moisture absorption, and chemical stability can significantly impact the longevity and performance of these materials. Industry reports indicate that UV radiation can lead to degradation in composite materials, resulting in a decrease in tensile strength by up to 30% over time. Therefore, selecting carbon fiber bars specifically designed with UV-resistant coatings or additives is essential for outdoor applications, ensuring they maintain structural integrity even in harsh conditions.

Moisture exposure can also affect the performance of pultruded carbon fiber bars. According to a study published in the Journal of Composite Materials, moisture absorption in standard composites can increase weight by more than 5% over prolonged periods, ultimately leading to mechanical failures. In contrast, advanced pultruded carbon fibers with hydrophobic treatments have shown reduced moisture uptake, enhancing their durability and reliability. Additionally, chemical resistance is a vital consideration; selecting materials with proven resistance to common industrial chemicals can prevent degradation and extend the service life of the carbon fiber bars in various environments. By prioritizing UV stability, moisture resistance, and chemical durability, manufacturers can ensure the optimal choice for their specific needs.

When selecting the right pultruded carbon fiber bar, a delicate balance between cost and performance is crucial. According to a 2021 report by MarketsandMarkets, the global carbon fiber market is projected to grow from $3.4 billion in 2021 to $6.1 billion by 2026, underscoring the rising demand for high-performance materials across various industries. However, the cost of pultruded carbon fiber, which can range from $20 to $80 per pound, often raises questions about its economic viability compared to alternatives like fiberglass or aluminum.

Performance metrics, such as tensile strength and thermal stability, are critical in assessing the value of pultruded carbon fiber. A study published in the Journal of Composite Materials indicated that carbon fiber bars offer a tensile strength of approximately 4000 MPa, significantly outperforming fiberglass, which averages around 450 MPa. While the initial investment in carbon fiber may be higher, its superior properties contribute to long-term savings by reducing maintenance costs and enhancing the lifespan of the final product. Manufacturers must carefully analyze these economic factors, ensuring they choose a material that not only fits their budget but also meets performance expectations for their specific applications.

| Characteristic | Option A | Option B | Option C |

|---|---|---|---|

| Cost per Meter | $25 | $30 | $28 |

| Tensile Strength (MPa) | 600 | 700 | 650 |

| Weight (kg/m) | 1.2 | 1.5 | 1.3 |

| Flexural Modulus (GPa) | 40 | 45 | 43 |

| Corrosion Resistance | Medium | High | Medium |

When selecting a pultruded carbon fiber bar, understanding manufacturer specifications is crucial for ensuring you meet quality standards and certifications. Manufacturers often provide detailed specifications that outline the mechanical properties, thermal resistance, and chemical compatibility of their products. This information not only guarantees product reliability but also helps in determining suitability for specific applications, whether in aerospace, automotive, or industrial settings.

Certifications play a key role in ensuring that the carbon fiber bar meets industry standards. Look for compliance with international norms such as ASTM or ISO, which can offer assurance regarding the material's performance and safety. Additionally, inquire about the manufacturer's quality control processes and testing methods. A reputable supplier should be transparent about their certifications and able to provide documentation verifying the materials used in their pultruded carbon fiber bars. By prioritizing these specifications, you can confidently choose a product that delivers durability and performance in your intended application.