-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Choosing the right Carbon Fiber Laminate Sheet can be a daunting task. These sheets are popular for their strength and lightweight properties. However, not all sheets are created equal. It’s essential to know what you need for your specific project.

Consider the application. Different projects require different thicknesses and finishes. Some may need maximum strength, while others might prioritize flexibility. Understanding these aspects will guide you in selecting the right material.

Additionally, suppliers can vary greatly in quality and pricing. Researching and comparing options is vital. Sometimes, it may lead to oversights in understanding your project requirements. Balancing cost and quality can be tricky. Reflecting on these factors will ensure a more informed choice.

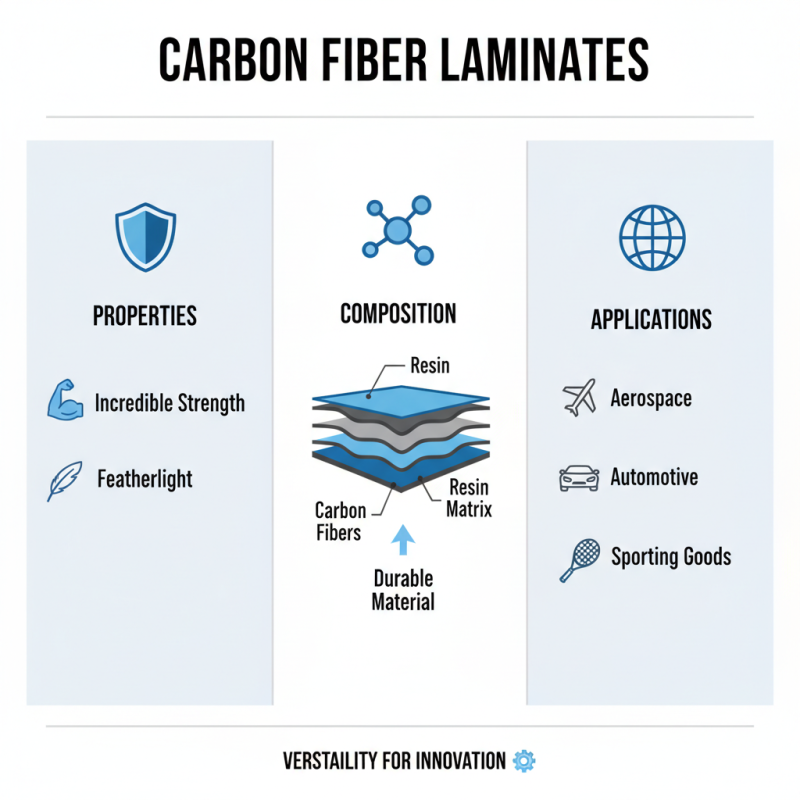

Carbon fiber laminates have gained immense popularity in various industries. They offer a fascinating combination of strength and lightweight properties. These sheets consist of layers of carbon fibers embedded in resin. The process creates a durable material ideal for a range of applications. Their versatility allows use in aerospace, automotive, and sporting goods.

Understanding the types of carbon fiber laminates is crucial. Not all laminates are created equal. Some are designed for high strength, while others focus on flexibility. Thickness and weave patterns also play a role in performance. A thicker laminate might be stronger but less flexible. Different resins can also change the characteristics of the sheet. You may find it challenging to choose the right one initially. Testing a few samples can help clarify which suits your specific needs best. This experimentation process is often overlooked but can lead to discovering the perfect material for your project.

Choosing the right carbon fiber laminate sheet for your project involves several key factors. The thickness of the laminate is crucial. Thicker sheets provide additional strength but may be heavier. According to the Composite Materials Handbook, the ideal thickness varies from 0.5mm to 2mm for most applications. This range balances weight and durability.

Another important consideration is the orientation of the fibers. Uni-directional sheets offer strength in one direction, while woven sheets provide multi-directional support. Understanding the load requirements of your project is essential. Misjudging the fiber orientation can lead to structural failures, as illustrated in numerous case studies from engineering reports.

Consider the resin type as well. Epoxy resins are common for their high strength-to-weight ratio. However, they can be brittle, especially under impact. Research indicates that about 25% of project failures result from improper resin choices. Check the environmental factors too. Moisture resistance and UV stability are often overlooked but can severely affect performance over time. Prioritize these key aspects to ensure your project’s success.

Choosing the right carbon fiber laminate sheet requires careful consideration of various grades and types available. Different projects demand different properties. For lightweight applications, consider high tensile strength laminates. These sheets hold significant weight while remaining durable. They are ideal for aerospace and automotive uses.

However, it's essential to understand that not all laminates are created equal. Some offer better stiffness, while others excel in flexibility. Evaluate your project requirements. Will the laminate need to withstand high temperatures? If so, specific grades are more heat-resistant. Test different options to find the perfect fit; you might be surprised by the performance of a lesser-known type.

When assessing carbon fiber laminates, don't overlook thickness and weave patterns. Thicker sheets often provide more durability but may sacrifice flexibility. A plain weave offers uniform strength, while a twill weave provides better strength-to-weight ratios. Assess your needs and experiment with samples before making a decision. This iterative process can lead to unexpected insights and help refine your choice.

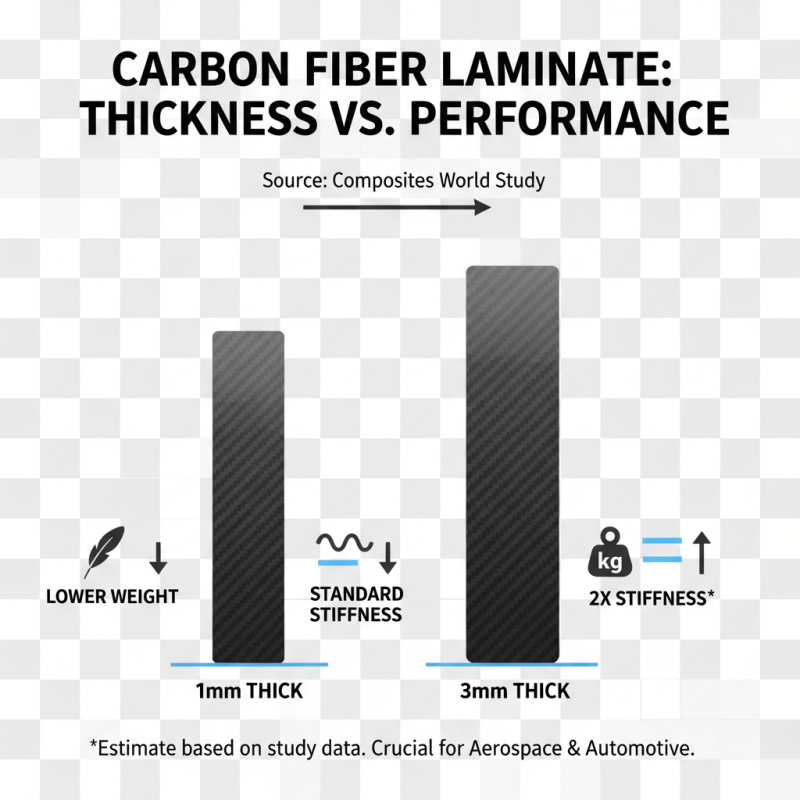

When selecting a carbon fiber laminate sheet, thickness and weight play crucial roles in performance. Thicker sheets provide higher stiffness but also increase weight. For example, a study by Composites World shows that a 3mm sheet can be twice as stiff as a 1mm sheet but adds significant mass. This is critical for applications in aerospace or automotive industries, where every ounce counts.

Consider the project's specific requirements. If weight savings are paramount, a thinner sheet may be more appropriate. However, it’s essential to evaluate if it compromises strength. Sometimes, using a slightly thicker sheet can deliver better overall performance.

Tips: Always check the tensile strength values. A higher strength-to-weight ratio indicates better performance.

Another factor is the intended environment. A lightweight laminate might excel in dry conditions but may not perform well in high humidity. Balancing these factors can lead to thoughtful design choices. Testing different configurations can yield insights. Don't hesitate to revisit your selections; sometimes, the best decisions come after reassessment.

Carbon fiber laminates are transforming several industries. Their strength and lightweight properties make them ideal in aerospace, automotive, and sports equipment. In aerospace, carbon fiber reinforces structures, improving fuel efficiency. In the automotive industry, these materials enhance performance while reducing weight. High-end sports equipment, like bikes and surfboards, benefits from carbon fiber's resilience.

When considering carbon fiber laminate sheets, think about your project's specific needs. Different applications may require varying thicknesses and finishes. You might also wonder about the recommended fiber orientation. Getting these factors right is crucial. Small mistakes can lead to project failures.

Tips: Always analyze the environmental conditions where the laminate will be used. Will it endure moisture or extreme temperatures? Conduct tests if needed. Moreover, consider your budget. Some laminates may look appealing but may not suit your financial limits. Research alternatives that balance cost and quality effectively. Don’t hesitate to seek expert advice when in doubt.