-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In recent years, the construction and manufacturing industries have increasingly turned to innovative materials. Among these, the "Carbon Fiber Laminate Sheet" stands out. According to industry reports, the global carbon fiber market is projected to reach $7.5 billion by 2026, showcasing a significant shift towards high-performance materials.

The advantages of Carbon Fiber Laminate Sheet are compelling. They offer high strength-to-weight ratios, making them ideal for aerospace and automotive applications. For example, a carbon fiber part can be lighter and stronger than its metal counterpart. This can lead to improved fuel efficiency and performance in vehicles. However, the cost remains a challenge for many manufacturers, requiring careful consideration.

Another point to reflect on is the sustainability of carbon fiber production. While it offers remarkable benefits, the environmental impact has raised questions. Some manufacturers are beginning to explore recycling methods, but there is still a long way to go. Ultimately, choosing Carbon Fiber Laminate Sheet opens up new possibilities, yet it asks us to weigh performance against environmental responsibilities.

Carbon fiber laminate sheets are becoming increasingly popular in various industries. Their unique properties make them ideal for many applications. First, the lightweight nature of carbon fiber reduces the overall weight of structures. This is particularly beneficial in aerospace and automotive projects, where every gram matters. The stiffness of these sheets adds strength without compromising performance.

Another major advantage is their resistance to corrosion and chemicals. Unlike metals, carbon fiber does not rust or degrade when exposed to harsh environments. This longevity makes it a cost-effective choice over time. These sheets can endure extreme temperatures and moisture, which can be a headache for other materials.

However, working with carbon fiber does come with challenges. The manufacturing process can be complicated and often requires specialized tooling. Mistakes can lead to waste and added costs. Designers must also consider the laminating process, as inconsistencies may affect the final product’s performance. Such intricacies require careful planning and attention to detail. It's crucial to weigh these factors carefully before selecting carbon fiber laminate sheets for your project.

| Feature | Description | Benefits |

|---|---|---|

| Lightweight | Carbon fiber is significantly lighter than metals like aluminum and steel. | Reduces overall project weight, enhancing performance and fuel efficiency. |

| High Strength | Offers incredible tensile strength, exceeding that of steel. | Delivers durability and structural integrity in demanding applications. |

| Corrosion Resistance | Resistant to chemical and environmental degradation. | Longer lifespan and reduced maintenance costs. |

| Versatility | Can be molded into various shapes for different applications. | Ideal for custom projects across industries such as automotive, aerospace, and sports equipment. |

| Thermal Stability | Maintains its properties across varying temperatures. | Reliable performance in both hot and cold environments. |

When comparing carbon fiber laminate sheets to other composite materials, several factors stand out. The strength-to-weight ratio of carbon fiber is exceptional. Its lightweight nature allows for easy handling. Other materials like fiberglass offer decent strength, but they often weigh more. This can be a crucial factor in applications such as aerospace and automotive industries.

Another aspect to consider is durability. Carbon fiber has excellent resistance to fatigue and chemical exposure. This makes it suitable for demanding environments. Meanwhile, materials like Kevlar can provide impact resistance but may not match carbon fiber in overall performance. However, the cost of carbon fiber is significantly higher. This can lead to budget constraints in some projects, an important factor to weigh.

Moreover, the manufacturing process of carbon fiber can be complex. Custom shapes and sizes often require advanced technology. This variability can lead to inconsistencies in quality. It is essential to have proper quality control to avoid potential failures. While making a choice, one must consider the specific requirements of the project. Balancing performance, cost, and durability is a challenge but necessary for success.

This chart compares the tensile strength, weight, and cost of carbon fiber laminate sheets with other common composite materials such as fiberglass and aramid fiber. The data illustrates the advantages of carbon fiber in terms of strength-to-weight ratio, which makes it a preferable choice for various engineering applications.

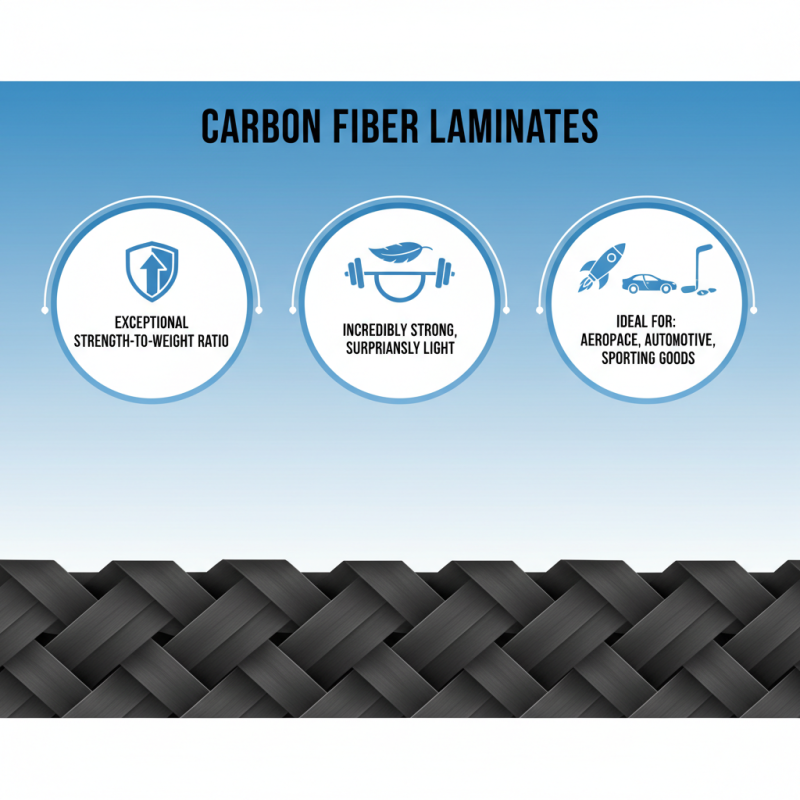

Carbon fiber laminate sheets are becoming increasingly popular in various projects. One key reason is their exceptional strength-to-weight ratio. They are incredibly strong yet surprisingly light. This unique balance makes them ideal for applications in aerospace, automotive, and even sporting goods.

When creating products, every gram matters. Carbon fiber offers substantial strength without the bulk. This can lead to improved performance and efficiency. For example, a carbon fiber bike frame can be lighter than aluminum frames while providing more rigidity. However, it can be challenging to work with. Cutting and shaping carbon fiber requires special tools and skills.

Another consideration is cost. Carbon fiber materials can be more expensive compared to traditional materials. It’s essential to evaluate whether the benefits justify the price for your specific project. Each use case might require different properties. Ultimately, understanding these dynamics will help you make informed decisions.

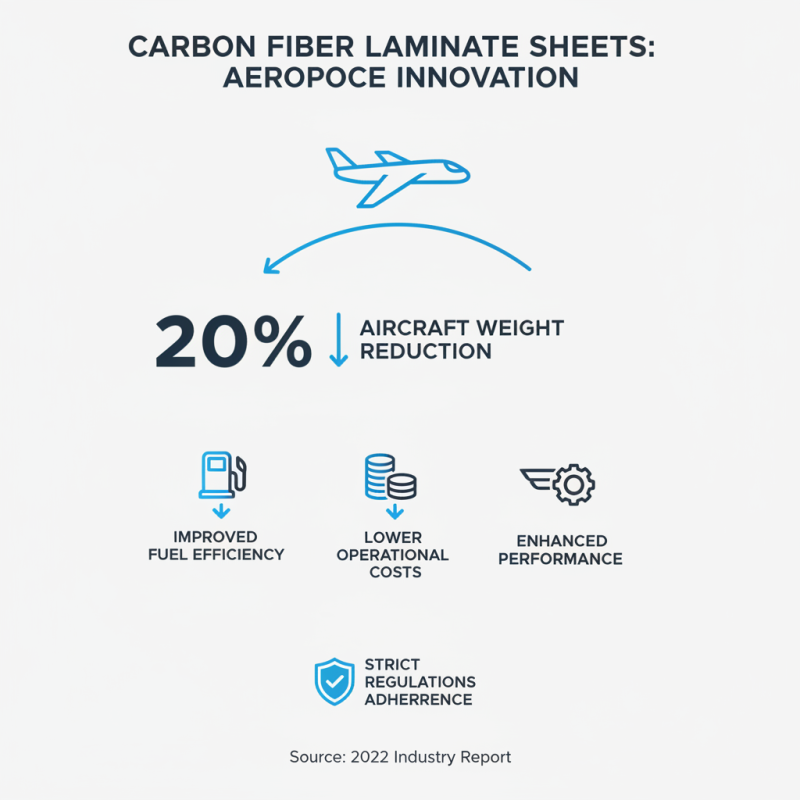

Carbon fiber laminate sheets are increasingly used across various industries due to their impressive properties. The aerospace sector is a key area, where weight reduction is critical. According to a 2022 industry report, using carbon fiber can reduce aircraft weight by up to 20%. This directly impacts fuel efficiency and operational costs. Aircraft manufacturers seek these materials to enhance performance while adhering to strict regulations.

In automotive applications, carbon fiber laminate sheets also shine. They contribute to lightweight vehicle designs, improving speed and handling. A study highlighted that cars incorporating carbon fiber can achieve up to 15% better fuel efficiency. However, not all manufacturers fully leverage this potential. Some still rely on traditional materials, missing out on the benefits offered by composites.

The sporting goods industry embraces carbon fiber for its strength-to-weight ratio. Equipment like bicycles and tennis rackets made from carbon fiber provide superior performance. However, production costs remain a challenge, limiting widespread adoption. Balancing quality and affordability is crucial for broader acceptance in these markets. Additionally, recycling and sustainability concerns have emerged, prompting a need for innovative solutions in the production process.

Carbon fiber laminate sheets have become a popular choice for various projects due to their impressive cost-effectiveness and durability. According to a report by MarketsandMarkets, the global carbon fiber market is projected to grow from $3.6 billion in 2020 to $7.7 billion by 2025, highlighting a trend that favors sustainable and efficient materials. These sheets are not only lightweight but also provide higher tensile strength compared to traditional materials like aluminum or steel.

The durability of carbon fiber laminate sheets is worth noting. They possess excellent resistance to corrosion and chemical damage. This trait makes them suitable for harsh environments. In aerospace and automotive applications, where a small weight reduction can translate into significant fuel savings, carbon fiber’s impact is profound. However, challenges remain. The initial manufacturing costs can be high, and it may take time for some industries to fully embrace this technology. In fact, while carbon fiber is 5 times stronger than steel, the upfront investment for organizations can be daunting.

Moreover, carbon fiber is noted for its fatigue resistance. Studies indicate that it retains its structural integrity even after enduring multiple cycles of stress. This performance can be particularly crucial in industries requiring consistent reliability. Nevertheless, some manufacturers still grapple with recycling the material effectively, which raises questions about long-term sustainability. Addressing these issues will be essential as the industry continues its shift towards greener alternatives.