-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

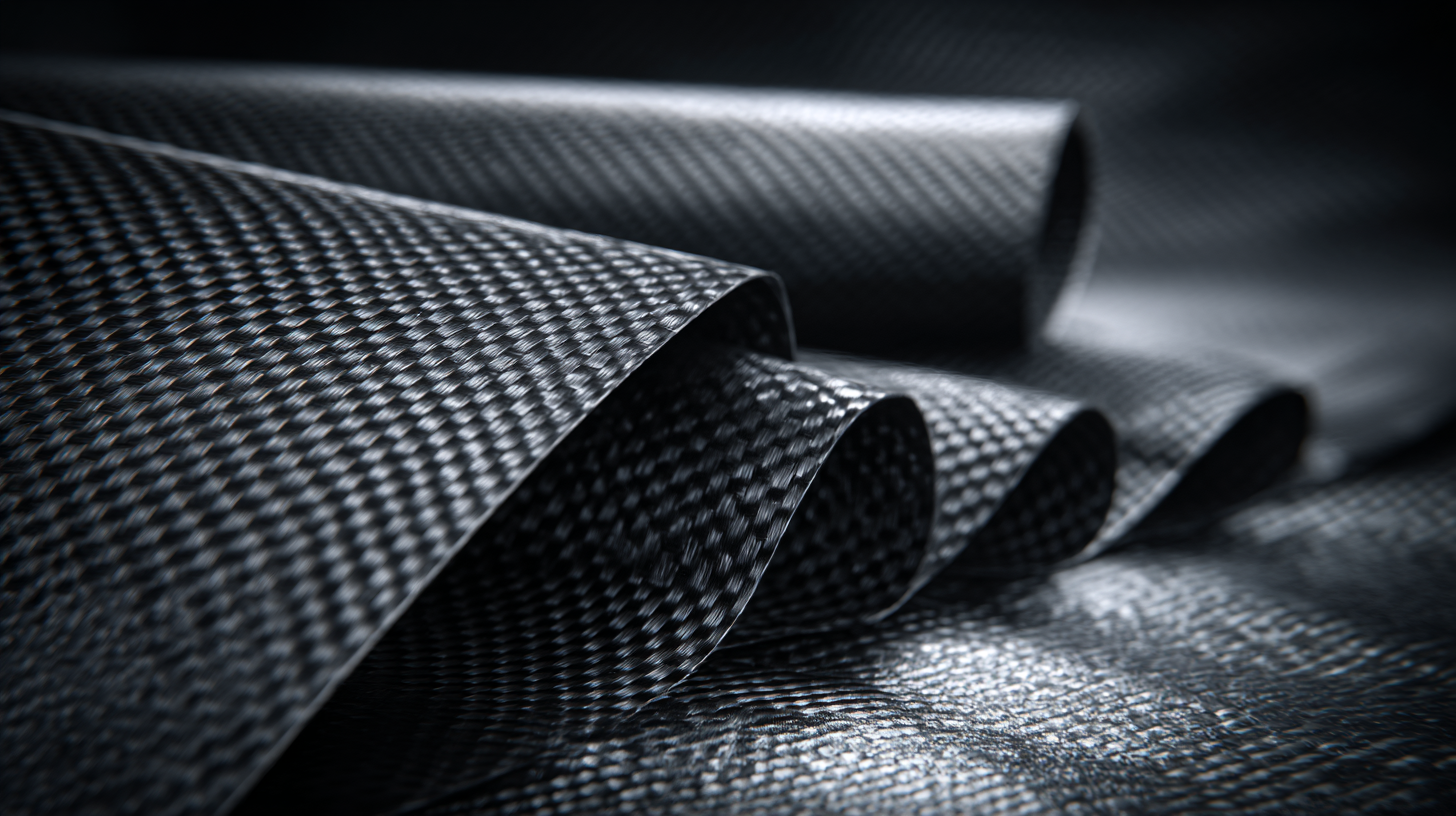

In recent years, the demand for advanced materials such as Flexible Carbon Fiber Sheets has surged, driven by the need for lightweight, high-strength solutions across various industries. According to a report by MarketsandMarkets, the carbon fiber market is projected to reach $5.4 billion by 2025, with a notable shift towards flexibility and versatility in applications ranging from aerospace to automotive and consumer goods. China's innovation in the production of Flexible Carbon Fiber Sheets is transforming global supply chains, enabling manufacturers to enhance performance while reducing weight. This blog will explore the key characteristics of these sheets, compare the best options available in China, and analyze their impact on supply chain efficiency and effectiveness in a competitive global marketplace.

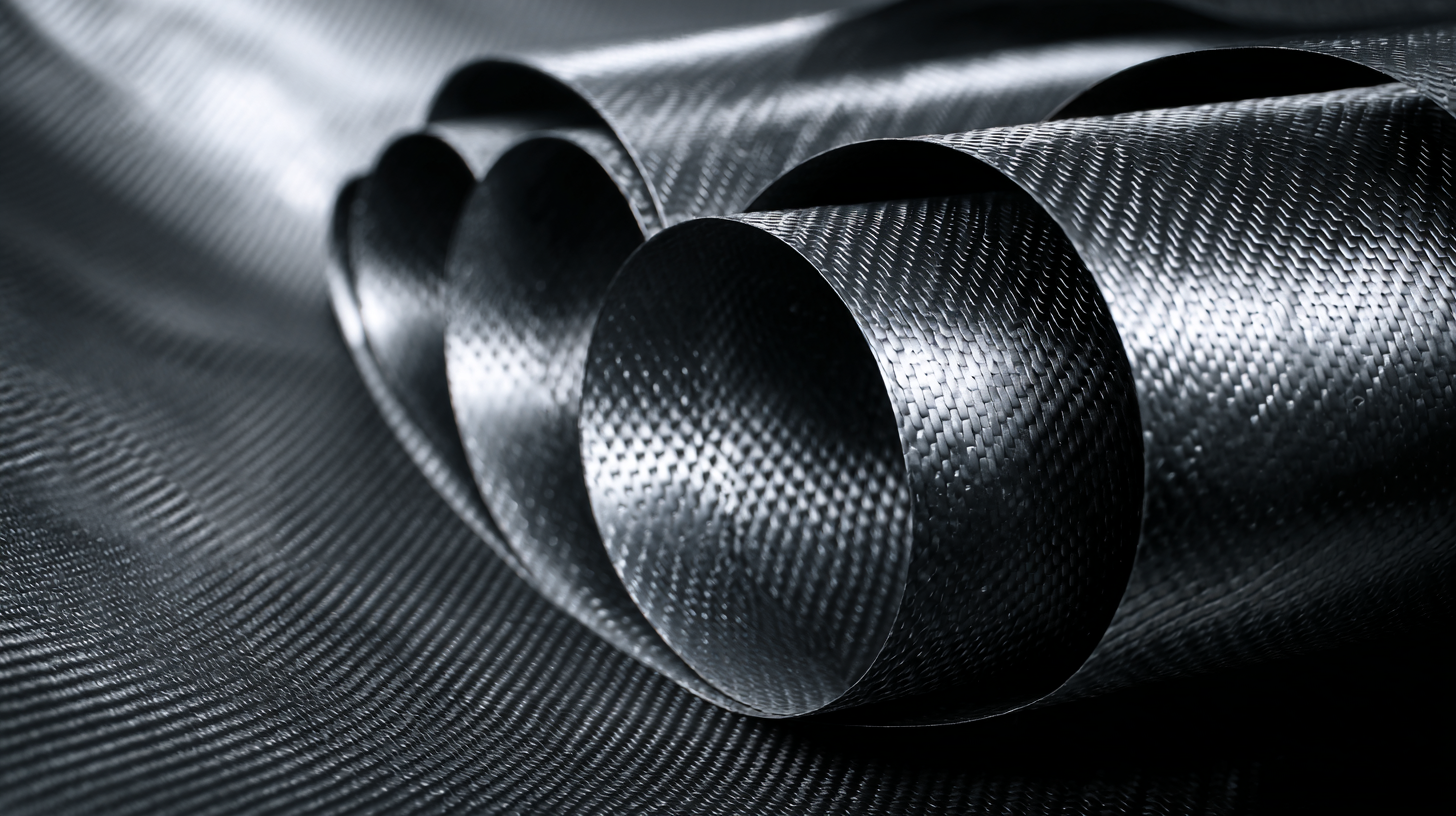

Flexible carbon fiber sheets have revolutionized various industries with their unique properties that enhance both performance and efficiency in supply chains. Renowned for their lightweight nature, these sheets provide an optimal balance between strength and flexibility, making them ideal for applications in aerospace, automotive, and manufacturing sectors. Their resistance to corrosion and extreme temperatures further accentuates their utility, allowing manufacturers to create products that withstand harsh environments without compromising on structural integrity.

What sets China’s flexible carbon fiber sheets apart is not just their mechanical advantages but also their innovative production processes. Advanced manufacturing techniques, combined with rigorous quality control, have positioned Chinese manufacturers at the forefront of the carbon fiber market. This ensures that businesses adopting these materials benefit from enhanced durability and reduced weight, leading to increased fuel efficiency and lower operational costs. As global supply chains continue to evolve, the integration of flexible carbon fiber sheets offers a significant competitive edge in delivering high-performance materials tailored to meet the demands of modern engineering and design.

In the evolving landscape of global supply chains, the significance of high-quality carbon fiber products cannot be overstated. As industries increasingly seek lightweight and durable materials, the demand for flexible carbon fiber sheets is surging. This uptick in demand is reflected in the projected growth of the global activated carbon market, expected to rise from $5.62 billion in 2025 to $10.04 billion by 2032, with a compound annual growth rate of 8.7%. This growth highlights the pivotal role that innovative materials, such as carbon fiber, play in enhancing supply chain efficiency and product performance across various sectors.

Choosing a reliable manufacturer for carbon fiber products is paramount for businesses aiming to leverage these advancements. Key factors include the manufacturer’s technology capabilities, experience in the market, and the ability to provide customization based on specific industry needs. Additionally, attention should be given to the manufacturer’s quality control processes and industry certifications, as these elements ensure that the products meet rigorous performance standards. By focusing on these aspects, companies can secure partnerships that will not only enhance their product offerings but also contribute to a more sustainable and competitive supply chain in the long run.

This bar chart illustrates the key factors affecting the choice of carbon fiber sheets in supply chains, including tensile strength, weight, and cost. Understanding these properties is crucial for manufacturers and consumers aiming to optimize their use of carbon fiber products.

China has established itself as a pivotal player in the global supply chain for carbon fiber solutions, offering highly flexible carbon fiber sheets that cater to a variety of industries. As demand for advanced materials grows, China's manufacturing capabilities enable it to provide high-quality products at competitive prices, fostering innovation across sectors such as aerospace, automotive, and construction. This access to an extensive range of materials significantly improves production efficiency and reduces lead times for businesses all over the world.

The integration of China's carbon fiber products into global supply chains is not merely about cost savings; it also promotes sustainability through lightweight materials that enhance energy efficiency. These flexible carbon fiber sheets play a crucial role in reducing overall vehicle weight, which can lead to lower fuel consumption and diminished environmental impact. As global industries strive for greener solutions, China's advancements in carbon fiber technology offer a pathway to meet these goals while maintaining robust supply chains that can adapt to fluctuating demands.

Flexible carbon fiber sheets are revolutionizing various industries by offering innovative solutions that enhance performance and sustainability. As a lightweight yet robust material, these sheets can be adapted for use in automotive designs, aerospace components, and even in cutting-edge wearable technology. According to recent assessments, the use of carbon fiber in composites is projected to grow significantly, driven by advances in manufacturing techniques and an increasing emphasis on sustainable practices across supply chains.

Tips: When considering carbon fiber applications, it's vital to evaluate their environmental impact. Opting for sheets made from recycled materials can significantly reduce carbon footprints. Furthermore, stay informed about the latest innovations in the field, such as the use of polymer-based composites for electromagnetic interference shielding, which demonstrates their versatility and effectiveness in enhancing product performance.

Interestingly, as highlighted in the latest material industry reports, the integration of carbon fiber with other advanced materials such as nanofibers is yielding even stronger composites. This synergy not only boosts the mechanical properties of the materials but also opens up new horizons for their application in sectors like aerospace and renewable energy. Therefore, businesses should explore these innovative combinations to stay at the forefront of material technology.

The future of carbon fiber technology is poised for transformative advancements that will significantly impact global supply chains. As industries increasingly adopt lightweight materials, carbon fiber has emerged as a crucial component in applications ranging from commercial vehicles to renewable energy solutions. Recent studies indicate that carbon fiber demand in regions like Jiangsu Province, which leads the nation, is expected to grow substantially. By 2025, the market for carbon fiber composites can potentially result in innovative applications in hydrogen storage systems and battery enclosures, responding to the ever-evolving needs of electric vehicles.

Moreover, the integration of artificial intelligence in manufacturing processes is set to revolutionize how carbon fiber products are developed and utilized. Companies are exploring AI-driven technologies to enhance precision and efficiency in production. The push towards sustainability, especially under the "dual carbon" goals in China, underscores the need for high-quality materials in the emerging green industries. Experts at recent forums highlight the critical role of advanced carbon materials in enabling this transformation, reflecting a broad trend towards adoption in sectors like offshore wind energy where lighter, stronger materials are crucial for larger turbine blades.