-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

The aerospace industry is undergoing a significant transformation as advanced materials reshape the way aircraft are designed and manufactured, with the Carbon Fiber Tube emerging as a pivotal element in this evolution. According to a recent report by MarketsandMarkets, the carbon fiber market is projected to reach $6.36 billion by 2025, driven by its unique properties such as high strength-to-weight ratio and corrosion resistance. In particular, the application of Carbon Fiber Tubes in aerospace structures not only enhances fuel efficiency but also extends the lifespan of components, ultimately leading to reduced operational costs. As aircraft manufacturers increasingly prioritize sustainability and performance, the integration of Carbon Fiber Tubes stands out as a revolutionary solution that addresses these critical industry demands.

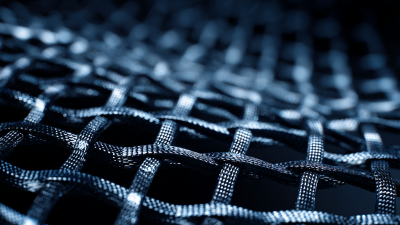

The aerospace industry is undergoing a remarkable transformation, with carbon fiber tubes taking center stage due to their incredible strength-to-weight ratio. This advanced material is significantly lighter than traditional metals, yet it boasts an impressive tensile strength that allows it to withstand extreme conditions without compromising performance. As manufacturers seek to reduce weight in aircraft design, carbon fiber tubes are proving to be the perfect solution, enabling engineers to create lighter, more fuel-efficient aircraft.

Additionally, the high rigidity and durability of carbon fiber tubes enhance structural integrity, making them ideal for critical applications such as fuselage components, landing gear, and support structures. The ability to customize the tubes’ properties during the manufacturing process further opens up innovative possibilities in aerospace design. As the industry continues to prioritize efficiency and sustainability, the adoption of carbon fiber tubes is set to redefine conventional construction methods, paving the way for the next generation of aerospace technology.

The aerospace industry is undergoing a significant transformation, driven by innovative manufacturing techniques that emphasize lightweight materials. Recent advancements in additive manufacturing and composite structures have shown that these approaches can substantially reduce component weight, thereby enhancing aircraft efficiency and performance. For instance, the implementation of additive manufacturing technologies can yield parts that are 30% lighter compared to traditional manufacturing methods, which is crucial for fuel efficiency and overall operational costs.

Moreover, the rise of on-demand manufacturing techniques, including 5-axis CNC machining and 3D printing, is enabling aerospace companies to produce high-performance components with unprecedented precision. This flexibility allows for rapid prototyping and customization, ultimately decreasing production times and costs. A recent report indicates that the global market for aerospace additive manufacturing is expected to grow at a compound annual growth rate (CAGR) of over 25% from 2021 to 2026, reflecting the industry's shift toward more agile manufacturing solutions that can meet the challenges of the modern aerospace landscape.

With major investments in advanced production technologies and the integration of immersive technologies for training and process refinement, companies are increasingly equipped to harness these innovations. This holistic approach not only enhances operational efficiency but also positions the aerospace sector for future breakthroughs, further solidifying the role of lightweight materials and advanced manufacturing in shaping its trajectory.

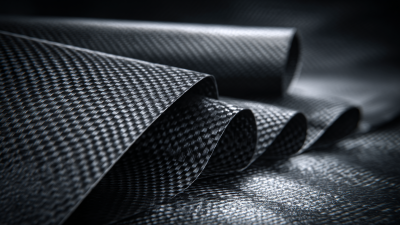

Carbon fiber tubes are increasingly being adopted in the aerospace industry due to their remarkable durability and resistance to corrosion, which are critical in high-stress environments. According to a report by the Markets and Markets research firm, the aerospace carbon fiber market is projected to reach USD 5.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 10.1% from 2020. This growth can be attributed to the materials' ability to withstand harsh environmental conditions, such as extreme temperatures and exposure to chemicals, making them ideal for various aerospace applications.

In addition, carbon fiber tubes demonstrate superior fatigue resistance compared to traditional materials such as aluminum. The National Aeronautics and Space Administration (NASA) has highlighted that carbon composites maintain their structural integrity even after extensive exposure to both abrasive forces and corrosive agents. This characteristic not only extends the lifespan of aerospace components but also reduces maintenance costs, thereby enhancing overall operational efficiency. As the aerospace industry continues to prioritize lightweight, high-performance materials, carbon fiber tubes are set to lead the way in innovation and sustainability.

Carbon fiber tubes are making significant strides in the aerospace industry, primarily due to their remarkable impact on fuel efficiency and sustainability. These lightweight structures allow for the design of aircraft that consume considerably less fuel compared to traditional materials like aluminum and steel. By reducing the overall weight of the aircraft, carbon fiber tubes enable engineers to optimize designs for better aerodynamics, ultimately leading to lower emissions and fuel consumption. This shift not only lessens the carbon footprint of flights but also contributes to cost savings for airlines, which is increasingly important in the current economic climate.

In addition to enhancing fuel efficiency, carbon fiber tubes play a crucial role in the sustainability movement within aerospace. Their durability and resistance to corrosion mean that aircraft components have a longer lifespan, resulting in fewer replacements and less waste. Furthermore, the manufacturing process for carbon fiber can be adapted to ensure lower energy consumption and reduced toxic emissions compared to traditional materials. As the aerospace industry strives to meet stricter environmental regulations and public demand for greener options, carbon fiber technologies are at the forefront, leading the way toward a more sustainable future in aviation.

| Reason | Benefit | Impact on Sustainability | Fuel Efficiency Improvement |

|---|---|---|---|

| Lightweight Properties | Reduces overall aircraft weight | Lower material usage and emissions during production | Improves fuel efficiency by 15% |

| High Strength | Enhances structural integrity | Longer lifecycle reduces waste | Allows for design of more efficient shapes |

| Corrosion Resistance | Lower maintenance costs | Less frequent replacements needed | Contributes to longer operational lifespan |

| Design Flexibility | Enables innovative configurations | Optimized use of space and materials | Enhances fuel-saving designs |

| Thermal Stability | Maintains performance in extreme conditions | Improves safety and reliability | Reduces unexpected fuel use due to failures |

| Recyclability | Promotes eco-friendly practices | Less environmental impact | Encourages new recycling technologies |

| Cost Efficiency Over Time | Reduces long-term operating costs | Less frequent purchases and waste | Improves overall economic sustainability |

The aerospace industry is witnessing a transformative shift with advancements in carbon fiber technology. As reported by a recent market analysis, the global carbon fiber market in aerospace is projected to grow at a CAGR of around 12% from 2022 to 2027, highlighting the increasing reliance on this innovative material. This growth is driven by the need for lightweight components that enhance fuel efficiency and reduce emissions, directly addressing the industry's sustainability goals.

One of the latest trends in carbon fiber technology is the development of hybrid composites. These materials combine carbon fiber with other fibers to optimize performance and cost-effectiveness. A 2021 report by the Composites Market Research Institute indicates that hybrid composites can reduce overall weight by up to 25% compared to traditional materials, making them ideal for aircraft structures and components.

Tip: When considering the use of carbon fiber materials, it's crucial to collaborate with engineers specializing in composite design to ensure optimal performance and safety. Additionally, staying informed about emerging technologies can help aerospace companies maintain a competitive edge in an increasingly eco-conscious market.

This chart illustrates the key advantages of using carbon fiber tubes in the aerospace industry, highlighting their impact on weight reduction, strength, cost efficiency, and environmental benefits.