-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

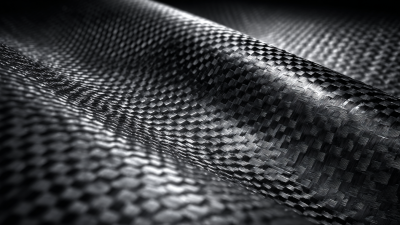

As industries strive for enhanced performance and sustainability, Carbon Fiber Composites have emerged as a transformative material in manufacturing innovations. According to a report by MarketsandMarkets, the global carbon fiber composites market is projected to grow from USD 4.12 billion in 2020 to USD 8.68 billion by 2025, at a CAGR of 16.4%—a testament to their increasing adoption across sectors such as aerospace, automotive, and sporting goods. The lightweight, high-strength properties of these composites offer significant advantages, including improved fuel efficiency and reduced emissions, aligning perfectly with the global push towards greener production methods. Furthermore, the versatility of Carbon Fiber Composites allows for innovative design possibilities, making them an essential component in the future of advanced manufacturing. This blog will explore seven compelling reasons why Carbon Fiber Composites are not merely an option but a necessity for innovation in manufacturing.

Carbon fiber composites are rapidly becoming a cornerstone of modern manufacturing, largely due to their unmatched strength-to-weight ratio. According to a report by Research and Markets, the global carbon fiber market is projected to grow from approximately $3.3 billion in 2020 to over $6.4 billion by 2025, representing a significant annual growth rate. This surge is driven by industries ranging from aerospace to automotive, where reducing weight without compromising strength is crucial for enhancing performance and fuel efficiency.

Carbon fiber composites are rapidly becoming a cornerstone of modern manufacturing, largely due to their unmatched strength-to-weight ratio. According to a report by Research and Markets, the global carbon fiber market is projected to grow from approximately $3.3 billion in 2020 to over $6.4 billion by 2025, representing a significant annual growth rate. This surge is driven by industries ranging from aerospace to automotive, where reducing weight without compromising strength is crucial for enhancing performance and fuel efficiency.

One of the most compelling aspects of carbon fiber composites is their incredible tensile strength, which is about five times that of steel when comparing equal weight materials. The automotive sector, for instance, can benefit greatly from this property; lighter vehicles not only consume less fuel but also achieve faster acceleration and improved handling. Additionally, a study published in the Journal of Composite Materials indicates that the use of carbon fiber can reduce the weight of car components by up to 50%, making it a game-changer in the quest for sustainability and innovation in manufacturing. As technology continues to advance, the potential applications of carbon fiber composites are virtually limitless, paving the way for a new era in manufacturing excellence.

Carbon fiber composites are rapidly transforming the landscape of manufacturing, particularly in how designers approach flexibility and innovation. These materials, celebrated for their high strength-to-weight ratio, allow manufacturers to create complex geometries and lightweight structures that meet the demands of modern engineering. According to a report by MarketsandMarkets, the global carbon fiber market is expected to reach $5.62 billion by 2026, growing at a CAGR of 10.5% over the next few years. This growth underscores the increasing integration of carbon fiber composites across various industries, including aerospace, automotive, and even consumer goods.

Design flexibility is markedly enhanced with carbon fiber composites, enabling manufacturers to experiment with shapes that were previously unattainable using traditional materials. For instance, in the automotive sector, companies like BMW have already embraced carbon fibers to produce lighter vehicles, resulting in better fuel efficiency without compromising safety.

Tip: When considering carbon fiber for your next project, prioritize understanding the specific properties of different composites. Certain formulations may offer improved impact resistance or thermal stability, making them suitable for specialized applications. Additionally, collaboration with suppliers early in the design process can ensure your project effectively leverages the full potential of carbon fiber technologies.

| Reason | Description | Impact |

|---|---|---|

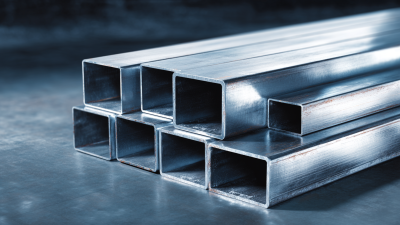

| Lightweight | Carbon fiber composites are significantly lighter than metals. | Reduces energy consumption in transportation. |

| High Strength | Carbon fibers offer superior strength-to-weight ratios. | Enables the design of stronger and more durable products. |

| Design Flexibility | Allows for complex shapes and designs to be easily manufactured. | Fosters innovative product development in various industries. |

| Corrosion Resistance | Carbon fiber materials are not susceptible to rust and corrosion. | Increases longevity and reduces maintenance costs. |

| Thermal Stability | Maintains structural integrity at high temperatures. | Ideal for use in high-performance applications. |

| Sustainability | Carbon fibers can be made from recyclable materials. | Contributes to eco-friendly manufacturing practices. |

| Cost Efficiency | Advancements in production techniques are lowering costs. | Makes carbon fiber composites more accessible to various industries. |

As industries increasingly focus on sustainability, carbon fiber composites emerge as a beacon of eco-friendly innovation.

Unlike traditional materials that demand extensive energy for production, carbon fiber can be manufactured more efficiently, significantly reducing carbon footprints.

The lightweight nature of these composites not only enhances energy efficiency during transit and usage, but also minimizes raw material waste, making them a superior choice for manufacturers striving to meet sustainability goals.

Moreover, the recyclability of carbon fiber composites is a game changer in the quest for a circular economy. Advances in recycling technologies allow these materials to be repurposed into new products, significantly lowering environmental impact.

This capability aligns with global agendas aimed at reducing landfill waste and promoting sustainable business practices.

As manufacturers integrate carbon fiber composites into their processes,

they not only contribute to a greener planet but also harness the strength and durability these materials offer, leading to innovative designs that stand the test of time.

The cost-effectiveness of carbon fiber innovations in mass production is increasingly recognized as a pivotal factor driving manufacturing transformations. According to a report by MarketsandMarkets, the global carbon fiber market is projected to reach $5.72 billion by 2026, growing at a CAGR of 10.6%. This growth underscores the material’s rising appeal for industries ranging from aerospace to automotive, where reducing weight while enhancing strength leads directly to better fuel efficiency and lower production costs.

Furthermore, the advantages of carbon fiber composites extend beyond raw material savings. A study by the American Composites Manufacturers Association (ACMA) suggests that manufacturers can achieve a reduction in lifecycle costs by up to 20% when utilizing carbon fiber over traditional materials. As mass production processes evolve, technologies such as automated fiber placement (AFP) and resin transfer molding (RTM) enable faster production rates, further driving down costs and making carbon fiber an increasingly viable option for large-scale applications. As companies harness these innovations, the prospect of carbon fiber becoming a cornerstone of advanced manufacturing systems is more tangible than ever.

Carbon fiber composites have emerged as a game-changer across various industries, thanks to their remarkable versatility. One of the most compelling aspects of carbon fiber is its lightweight nature combined with high strength, which allows for innovative applications in sectors ranging from aerospace to automotive. In aerospace, for instance, carbon fiber components reduce overall weight, leading to improved fuel efficiency and performance. Similarly, in the automotive industry, manufacturers leverage carbon fiber to enhance vehicle performance and safety without compromising on style.

When considering the adoption of carbon fiber composites, it’s vital to recognize their adaptability. Industries can explore various advanced applications, such as in sports equipment, where reduced weight can significantly impact performance. Additionally, in the construction sector, carbon fiber reinforcements can enhance the durability and lifespan of structures.

Tips for implementing carbon fiber composites include conducting thorough research on material properties to identify suitable applications. Collaboration with material scientists can also help in optimizing the manufacturing processes, ensuring that businesses reap the full benefits of carbon fiber technology. Staying updated with industry trends and advancements can provide insights into new potential applications, making it easier for companies to innovate and stay competitive.