-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

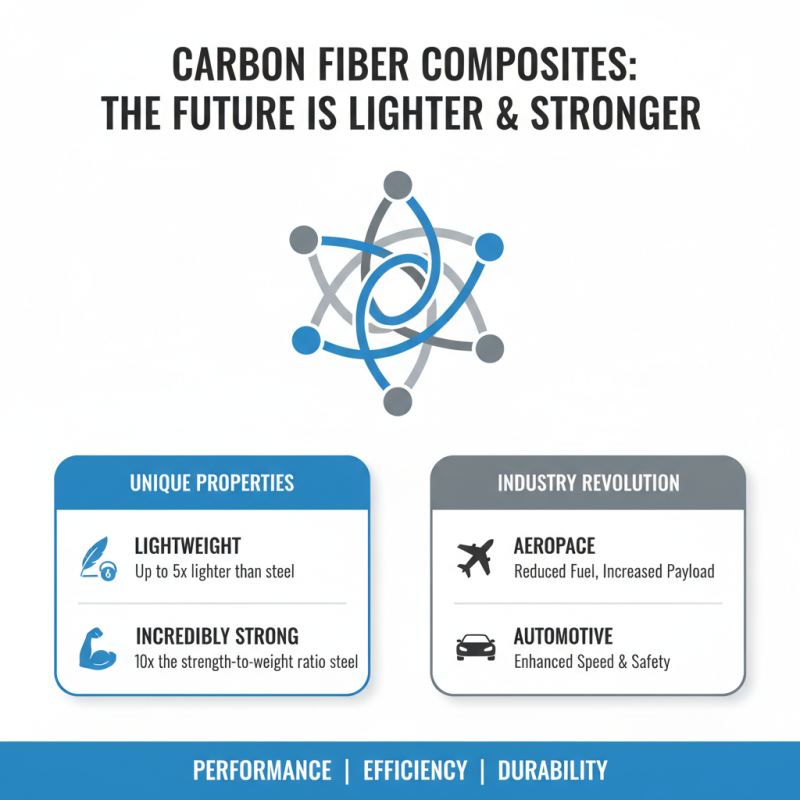

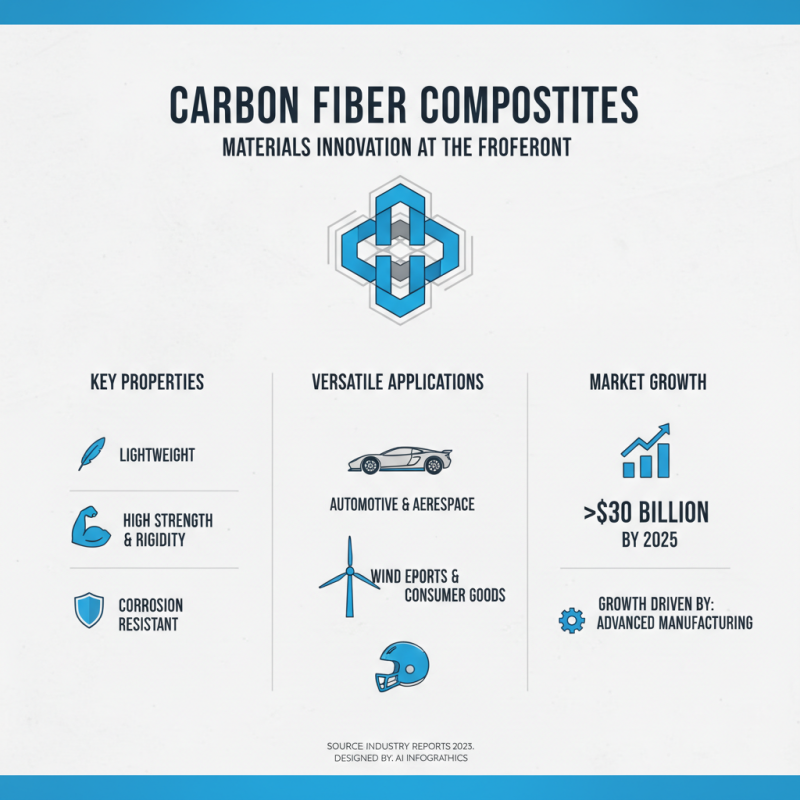

Carbon Fiber Composites are reshaping various industries, from aerospace to automotive. These materials are lighter and stronger than traditional options. According to a report from MarketsandMarkets, the global market for carbon fiber composites is expected to reach $30 billion by 2024.

Experts emphasize the advantages of Carbon Fiber Composites. Dr. Emily Chen, a leading materials scientist, states, "The efficiency gains in lightweighting through carbon fiber are remarkable." Yet, despite their benefits, challenges remain. The high cost of production can limit accessibility for some industries.

The potential of Carbon Fiber Composites is immense. They offer improvements in fuel efficiency and performance. Still, as we explore these materials, we must consider sustainability and recycling practices. Balancing innovation with responsibility is crucial for the future of Carbon Fiber Composites.

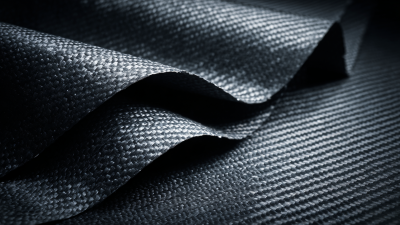

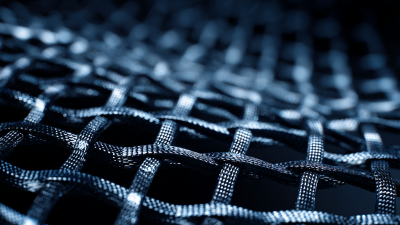

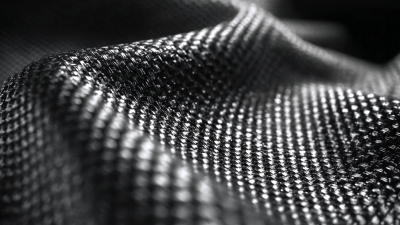

Carbon fiber composites are advanced materials composed of carbon fibers and a matrix, typically a polymer. The fibers themselves provide strength and rigidity, while the matrix binds the fibers and supports their structure. This combination results in a lightweight material that is much stronger than steel, making it ideal for various applications.

The individual components of these composites play a crucial role. Carbon fibers are thin strands that exhibit impressive tensile strength. The polymer matrix, usually epoxy, serves as the glue that holds everything together. It can also offer protection against environmental factors. However, production can be tricky. The fibers are sensitive to handling, and the matrix can be prone to cracking under stress. These challenges require careful consideration during the manufacturing process.

In many ways, carbon fiber composites push the boundaries of materials science. Their potential is evident in fields like aerospace and sports equipment. Yet, achieving the perfect balance of weight, strength, and flexibility remains a journey. Innovations must address the limitations of current composite technologies. As researchers explore new combinations, the future of carbon fiber composites looks promising, albeit with areas that need fine-tuning.

Carbon fiber composites are made by combining carbon fibers with a polymer matrix. This blend results in a material that is lightweight yet incredibly strong. The manufacturing process of these composites involves several key steps that ensure their effectiveness for various applications.

The first stage is the preparation of carbon fibers. These fibers are often derived from polyacrylonitrile (PAN). The fibers are spun into strands before being subjected to a high-temperature carbonization process. This step removes non-carbon atoms, enhancing their strength. The next phase involves mixing the carbon fibers with a resin system, often epoxy or polyester. This resin serves as a binding agent, providing the necessary flexibility and durability.

After mixing, the material undergoes curing. This phase solidifies the composite structure. It is crucial for achieving the desired mechanical properties. However, achieving uniformity in the curing process can be challenging. Uneven curing may lead to weak spots, affecting performance. Additionally, the need for precision in each step often requires careful monitoring and adjustments. Even small issues in the manufacturing process can lead to significant consequences later in use.

| Property | Description | Benefits |

|---|---|---|

| Lightweight | Carbon fiber composites are significantly lighter than traditional materials like steel or aluminum. | Reduces overall weight of products, leading to improved fuel efficiency in vehicles. |

| High Strength | Carbon fiber has a higher tensile strength compared to steel. | Provides enhanced durability and resistance to deformation. |

| Corrosion Resistance | Carbon fiber composites are not prone to rusting or corrosion. | Lowers maintenance costs and extends product lifecycle. |

| Versatility | Can be molded into different shapes and sizes during manufacturing. | Enables innovative designs and applications across various industries. |

| Thermal Stability | Maintains structural integrity at high temperatures. | Suitable for high-performance applications, such as aerospace components. |

Carbon fiber composites are revolutionizing various industries due to their unique properties. They are lightweight yet incredibly strong, making them ideal for applications where performance matters. For example, in aerospace, they help reduce fuel consumption and increase payload. In automotive sectors, these materials enhance speed while ensuring safety.

The use of carbon fiber composites in sports equipment is also notable. Athletes benefit from lighter gear that performs better. However, the manufacturing process can be complex. Sometimes, the cost can outweigh the benefits. Many industries are still figuring out how to integrate these materials efficiently.

In construction, carbon fiber enhances structural integrity without adding significant weight. This adaptability allows for innovative designs. Yet, there is a challenge in recycling these composites once they reach the end of their lifespan. As industries explore new applications, the need for sustainable solutions grows. These materials hold promise, but their full potential is still unfolding.

Carbon fiber composites have transformed various industries with their unique properties. These materials are lightweight yet incredibly strong, making them popular in aerospace and automotive design. For example, using carbon fiber in aircraft bodies reduces weight and enhances fuel efficiency. Cars made from these composites often show improved performance and better handling.

In modern technology, the applications extend beyond transportation. Sports equipment, like bicycles and tennis rackets, benefit from carbon fiber’s rigidity and reduced weight. Even in medical devices, carbon fiber's biocompatibility and strength provide durability and reliability. However, the high cost of production can pose challenges for widespread use. Some industries find it difficult to justify the investment despite the benefits. There’s a constant need for balance between cost and performance enhancements.

The evolving nature of carbon fiber composites presents an interesting dilemma. While their advantages are clear, innovation is crucial. Research continues to seek ways to lower production costs and improve recyclability. It's essential to address these challenges for future advancements. This ongoing quest for efficiency may shape the future of various high-tech applications.

Carbon fiber composites are at the forefront of materials innovation. Their lightweight yet strong properties make them ideal for multiple industries. Recent reports show that the carbon fiber composites market is projected to exceed $30 billion by 2025. This growth stems from advancements in manufacturing techniques, making these materials more accessible.

Future trends indicate a shift toward more sustainable practices. Innovations are focusing on recycling carbon fiber. Current processes are inefficient, yielding about 60% recycled material. However, new technologies aim to improve this rate significantly. Reducing waste is crucial in addressing environmental concerns.

Additionally, the integration of smart technologies promises exciting applications. Sensors embedded in carbon fiber composites can monitor structural integrity in real-time. The aerospace sector, for example, is exploring self-healing materials to enhance safety. Yet, challenges remain. Current developments may not be scalable for mass production. Addressing these issues is essential for the industry’s growth.