-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In recent years, the demand for lightweight yet strong materials in various industries has surged, making the Pultrusion Carbon Fiber Bar a focal point of innovation and manufacturing excellence. According to a market research report by ResearchAndMarkets, the global carbon fiber market is projected to reach $6.5 billion by 2025, driven primarily by advancements in manufacturing processes and the increasing adoption of carbon fiber composites in automotive, aerospace, and construction sectors. The unique properties of Pultrusion Carbon Fiber Bars, including their exceptional strength-to-weight ratio and corrosion resistance, position them as a superior choice for engineers and designers seeking reliable materials. Chinese manufacturers, known for their state-of-the-art production capabilities and cost-effectiveness, are now leading the way in this sector, offering high-quality Pultrusion Carbon Fiber Bars that meet international standards. This ultimate guide will explore the strengths of these innovative products, highlighting their applications, benefits, and the remarkable Chinese manufacturing prowess that backs them.

Carbon fiber bars have emerged as a paramount choice in modern manufacturing due to their exceptional properties and versatility. One of the primary advantages of carbon fiber is its high strength-to-weight ratio, which makes it an ideal material for applications where weight reduction is crucial. Industries such as aerospace, automotive, and construction benefit greatly from using carbon fiber bars, as they provide significant strength while adding minimal weight. This combination enhances performance and efficiency, enabling manufacturers to create products that meet rigorous standards without compromising on quality.

In addition to their mechanical advantages, carbon fiber bars offer superior resistance to corrosion and fatigue. Unlike traditional materials such as steel or aluminum, carbon fiber is less prone to rust and degradation over time, resulting in longer-lasting components. This durability not only reduces maintenance costs but also extends the lifespan of machinery and structures, making carbon fiber a wise investment for manufacturers looking to optimize their production processes. As Chinese manufacturing continues to excel in the field of advanced materials, the accessibility and innovation associated with carbon fiber bars are set to transform modern manufacturing practices, driving further advancements across various industries.

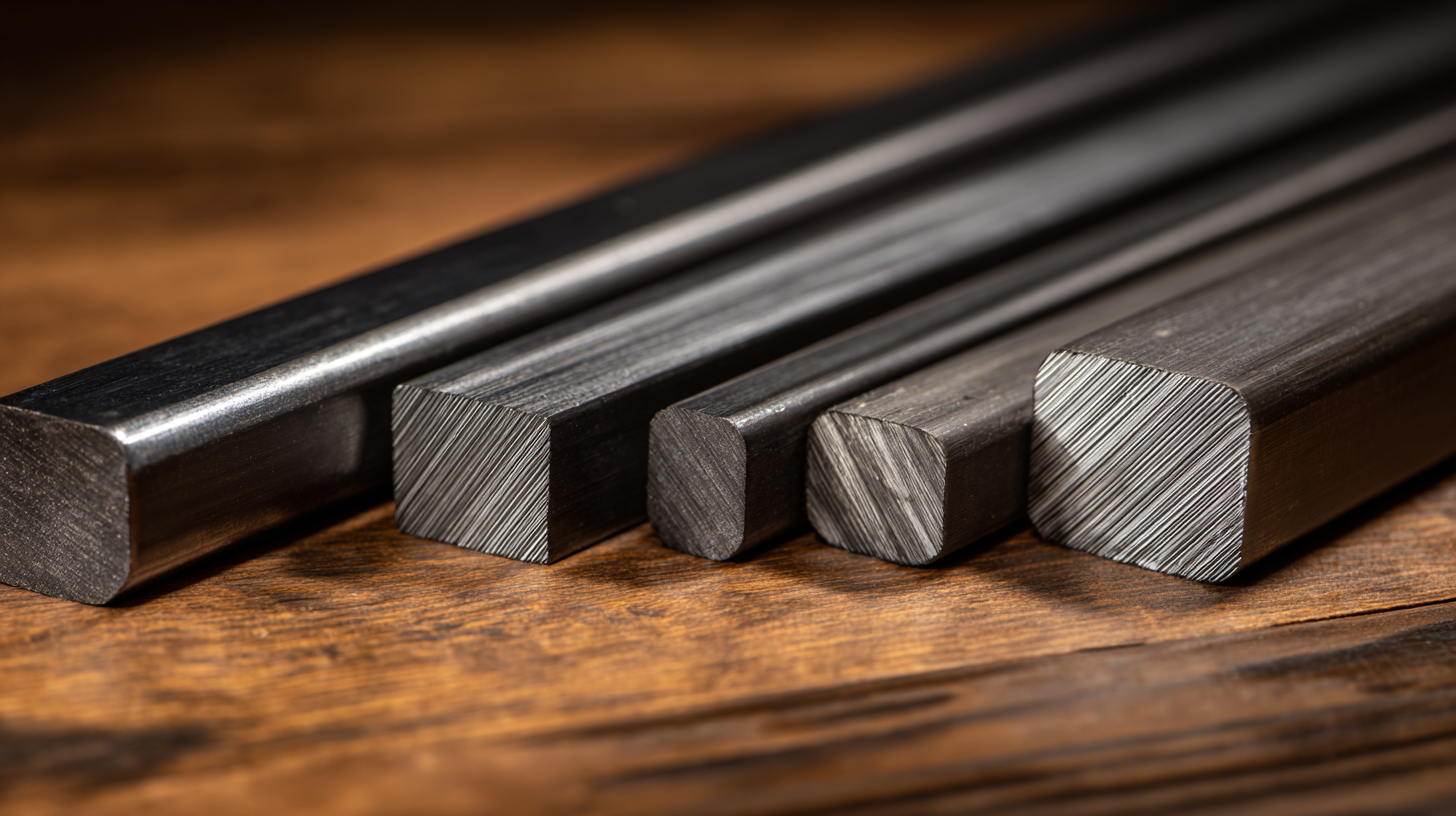

Pultrusion carbon fiber products have become increasingly popular due to their lightweight yet robust characteristics, making them ideal for a variety of applications ranging from aerospace to automotive. Different types of pultrusion carbon fiber bars exhibit unique properties that cater to specific needs. For instance, high modulus carbon fiber bars provide exceptional tensile strength, making them suitable for demanding structural applications where load-bearing capacity is crucial. On the other hand, specialty carbon fiber composites can be tailored for impact resistance, which is essential in industries where durability is paramount.

Pultrusion carbon fiber products have become increasingly popular due to their lightweight yet robust characteristics, making them ideal for a variety of applications ranging from aerospace to automotive. Different types of pultrusion carbon fiber bars exhibit unique properties that cater to specific needs. For instance, high modulus carbon fiber bars provide exceptional tensile strength, making them suitable for demanding structural applications where load-bearing capacity is crucial. On the other hand, specialty carbon fiber composites can be tailored for impact resistance, which is essential in industries where durability is paramount.

The manufacturing excellence found in China contributes significantly to the quality and variety of pultrusion carbon fiber products available in the market. Chinese manufacturers utilize state-of-the-art technology and advanced materials to create carbon fiber bars that not only meet international standards but often exceed them. These manufacturing capabilities allow for the production of hybrid composites that combine the benefits of both carbon and glass fibers, offering enhanced flexibility and strength. As a result, users have access to a diverse range of products tailored for specific engineering challenges, driving innovation in multiple sectors and showcasing the unique attributes of pultrusion carbon fiber technology.

Carbon fiber bars have gained significant traction across various industries due to their remarkable mechanical properties and versatility. In the aerospace sector, these bars play a critical role in lightweight construction, enhancing fuel efficiency without compromising structural integrity. The automotive industry also benefits from carbon fiber bars, as they contribute to the development of high-performance vehicles that are both robust and energy-efficient. Additionally, the medical field utilizes these materials in the creation of advanced prosthetics and surgical instruments, ensuring durability and precision.

Moreover, the expansion of carbon fiber applications is not limited to traditional sectors. Innovative uses in marine environments and construction demonstrate the adaptability of these materials. For instance, in marine applications, carbon fiber bars are integrated into ship hulls to improve strength-to-weight ratios, ultimately enhancing performance and fuel efficiency. Similarly, in construction, the reinforcement provided by these bars in composite materials leads to enhanced durability and sustainability in building practices. As industries continue to explore the full potential of carbon fiber, the prospects for continued innovation and application remain vast.

Chinese manufacturing has long been celebrated for its ability to produce high-quality carbon fiber products, particularly pultrusion carbon fiber bars that are both lightweight and remarkably strong. The advanced technology and refined processes employed in Chinese factories ensure that these bars meet rigorous industry standards. By leveraging state-of-the-art equipment and expertise, manufacturers are able to optimize the properties of carbon fiber, resulting in products that are durable, corrosion-resistant, and tailored to meet diverse performance requirements.

Chinese manufacturing has long been celebrated for its ability to produce high-quality carbon fiber products, particularly pultrusion carbon fiber bars that are both lightweight and remarkably strong. The advanced technology and refined processes employed in Chinese factories ensure that these bars meet rigorous industry standards. By leveraging state-of-the-art equipment and expertise, manufacturers are able to optimize the properties of carbon fiber, resulting in products that are durable, corrosion-resistant, and tailored to meet diverse performance requirements.

Tip: When choosing carbon fiber bars, look for manufacturers that provide detailed documentation of their quality control processes. This assurance can help ensure that the products meet your specific application needs.

Moreover, the economic advantages of Chinese manufacturing contribute to the accessibility of premium carbon fiber materials. By streamlining production and focusing on efficiency, manufacturers can offer competitive pricing without compromising on quality. This blend of affordability and excellence makes pultrusion carbon fiber bars an appealing choice for various industries, from aerospace to automotive.

Tip: Always request samples before making a bulk purchase; this way, you can evaluate the material's performance firsthand and make an informed decision based on your project's requirements.

Pultrusion carbon fiber bars have become increasingly popular in various industries due to their exceptional cost-effectiveness and striking durability. Manufacturing these bars using advanced pultrusion techniques allows for consistent quality and performance at lower production costs. This means businesses can enjoy the benefits of lightweight, high-strength materials without straining their budgets. Chinese manufacturers, known for their expertise in this area, deliver an impressive product that meets international quality standards while remaining competitive in pricing.

When considering pultrusion carbon fiber bars, here are some tips to maximize your investment. First, assess the specific requirements of your application to choose the right specifications—such as size, strength, and environmental resistance. Understanding the unique properties of carbon fiber will help you select the best material for your needs. Second, partner with reputable manufacturers that offer comprehensive services, including custom solutions and quality assurance. This partnership will ensure you receive a product that not only meets your expectations but also enhances the overall performance of your projects.