-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In the realm of Carbon Fiber Sheet Cutting, precision and technique are crucial. Renowned expert Dr. Emily Chen states, “Every cut matters; it defines the end product.” Her extensive experience highlights the importance of mastering various cutting techniques.

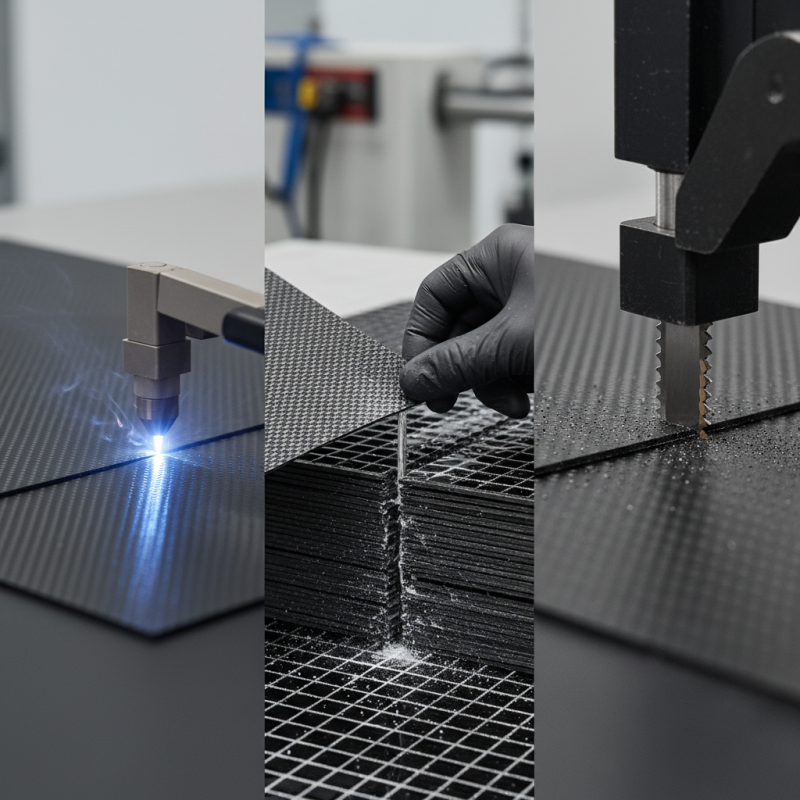

Cutting carbon fiber sheets can prove challenging. The material's unique properties require specialized methods. Common techniques include laser cutting, water jet cutting, and blade cutting. Each method has its advantages and drawbacks. For instance, laser cutting offers precision but can introduce heat, potentially damaging the fibers. Conversely, blade cutting may result in frayed edges if not executed correctly.

Adopting the right cutting method can impact overall project success. Cost efficiency and material waste are often overlooked aspects. As the industry evolves, so do cutting technologies. Experimenting with different techniques is essential. Continuous learning from mistakes can lead to better outcomes in Carbon Fiber Sheet Cutting.

Carbon fiber sheets have gained significant traction in various industries due to their exceptional strength-to-weight ratio. These sheets are crucial in aerospace, automotive, and sporting goods. According to a market research report by Research and Markets, the global carbon fiber market is projected to reach $5.7 billion by 2027. This growth reflects their rising popularity across different applications.

In aerospace, carbon fiber sheets are used to build lightweight components that enhance fuel efficiency. The automotive sector also benefits from these sheets. Many manufacturers seek to reduce vehicle weight to improve performance. A study from the National Renewable Energy Laboratory indicates that reducing vehicle weight by 10% can enhance fuel efficiency by 6-8%. However, cutting these sheets can be challenging. Not all methods produce clean edges or minimize splintering, leading to frequent rework and waste.

In sports, carbon fiber enhances equipment durability and performance, from bicycles to tennis rackets. Yet, not all applications are ideal. Some users report difficulty in maintenance and repair. The production process can lead to flaws in the sheets, impacting reliability. So, the examination of cutting methods must also consider these factors. Efficient cutting techniques could improve usability and material longevity, proving how vital precise processes are in maximizing carbon fiber's potential.

Cutting carbon fiber sheets requires specialized tools. Traditional blades can dull quickly. A vacuum table saw is an excellent choice. It provides precision while minimizing dust. However, users need to calibrate it carefully. Otherwise, cuts might end up uneven.

Another option is using a water jet cutter. This method is effective for intricate designs. It creates smooth edges without impacting the material's integrity. Yet, the setup costs can be high. Some operators may find it challenging to operate.

Hand tools like scissors or shears are also popular. They work well for small projects. But, they demand good technique. Improper cutting may fray the edges. For some, this can lead to wastage. Each method has its pros and cons. Knowing which tool suits your project is crucial.

| Cutting Method | Tool Used | Material Type | Thickness Range (mm) | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Water Jet Cutting | Water Jet Cutter | Carbon Fiber | 1-50 | No thermal distortion, high precision | Higher operational cost |

| CNC Machining | CNC Router/Mill | Carbon Fiber Sheets | 0.5-25 | High precision, can achieve complex shapes | Dust generation, may require finishing |

| Blade Cutting | Circular Saw, Jigsaw | Prepreg Carbon Fiber | 0.2-10 | Cost-effective, easier setup | May cause fraying, less accurate |

| Laser Cutting | Laser Cutter | Carbon Fiber Composites | 1-15 | Fast, precise cuts | May require post-processing |

Cutting carbon fiber sheets requires precision and the right techniques. Start with a sturdy work surface. Use a sharp utility knife or scissors. However, remember that not all cuts come out perfect. A slight slip can lead to a jagged edge. This may affect your project later. So, focus while cutting.

Measure carefully before making any cuts. Use a straight edge as a guide. This helps in maintaining accuracy. However, mistakes can happen. If the sheet isn't cut straight, it might need trimming later. That can be frustrating, especially when working on detailed projects.

Practice is key. Try cutting scrap pieces to get used to the material. Sometimes, the blade may dull quickly. This can lead to uneven cuts. Always check your tools before starting. The quality of your cuts directly impacts your final product. Take your time and reflect on what works best for you.

When cutting carbon fiber sheets, using power tools correctly is crucial. The right technique can make your work more efficient and precise. Power tools can create clean edges and expedite the cutting process. However, improper use can lead to mistakes. Always wear safety gear to protect your eyes and lungs. The dust from cutting carbon fiber is harmful.

Tips: Start with a sharp blade. A dull blade can cause fraying. Consider using a fine-toothed saw or a water jet cutter. They provide smooth cuts without damaging the fibers. Test your tool on a scrap piece before cutting your final piece. Adjust your speed based on the thickness of the material. It helps to maintain control and achieve a clean finish.

Power tools generate heat during cutting. Too much heat can compromise the integrity of the carbon fiber. Monitor the temperature and pause if needed. This may feel inefficient, but it prevents costly mistakes later. Remember that patience is key. Rushing can lead to errors. Reflect on each step to ensure you are on the right path.

This chart illustrates the effectiveness of different power tools and methods used for cutting carbon fiber sheets. The data reflects the average cutting speed (in mm/min) and the quality of the cut (rated from 1 to 5, with 5 being the best) based on user feedback.

When cutting carbon fiber materials, safety is paramount. Carbon fiber dust can be hazardous. Always wear a proper respirator and safety goggles. This protects your lungs and eyes from tiny, sharp particles. Gloves are also essential. They help prevent skin irritation from the fibers.

Tips: Ensure your workspace is well-ventilated. This reduces dust accumulation and maintains air quality. Consider using a dedicated cutting area to minimize mess. It’s crucial to keep your equipment clean. Accumulated debris can affect your cutting precision.

Pay attention to your posture while cutting. Poor posture can lead to fatigue and injury. Take breaks to stretch and reset your position. Each cut should be made carefully, adapting techniques as needed. Sometimes you might notice that your initial method isn’t effective. Don't hesitate to try different approaches until you find what works best. Cutting carbon fiber can be tricky, and that’s okay. Learning from each attempt helps you improve. Stay aware and adjust your methods when necessary.