-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In recent years, the utilization of Pultruded Carbon Fiber Rods has gained significant traction within various modern engineering applications. According to the market research report by Smith & Co., the global demand for carbon fiber reinforced composites is projected to reach approximately $30 billion by 2025, with pultrusion techniques becoming increasingly popular due to their efficiency and versatility. These advanced materials not only provide exceptional strength-to-weight ratios but also showcase remarkable resistance to environmental factors, making them a go-to solution for industries ranging from aerospace to civil engineering.

Dr. Emily Johnson, a leading expert in composite materials and a consultant for several engineering firms, emphasizes the transformative impact of Pultruded Carbon Fiber Rods: "The unique properties of pultruded carbon fiber allow engineers to innovate and design structures that were previously thought impossible." As engineering challenges continue to evolve, integrating Pultruded Carbon Fiber Rods into projects offers a pathway to enhanced durability, lighter constructions, and superior performance.

This article explores the top five benefits of adopting Pultruded Carbon Fiber Rods, highlighting their significance in pushing the boundaries of modern engineering and paving the way for future advancements.

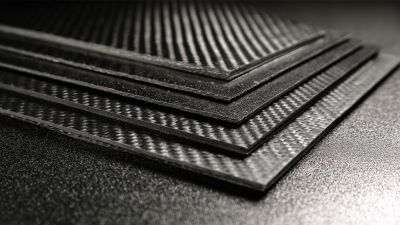

Pultruded carbon fiber rods are increasingly favored in modern engineering due to their remarkable high strength-to-weight ratio. This unique property allows engineers to design structures that are both lightweight and exceptionally durable. The ability to reduce weight without compromising strength means that these rods are ideal for applications in aerospace, automotive, and marine industries, where minimizing weight can lead to enhanced fuel efficiency and improved performance.

Moreover, the high strength-to-weight ratio of pultruded carbon fiber rods enables the creation of innovative structural designs that would be impossible with traditional materials. Engineers can push the boundaries of design, incorporating more intricate shapes and configurations that maintain structural integrity while reducing overall mass. This not only results in lighter structures but also opens up new possibilities for sustainable engineering practices, as the reduced material usage contributes to lower environmental impact in manufacturing and construction.

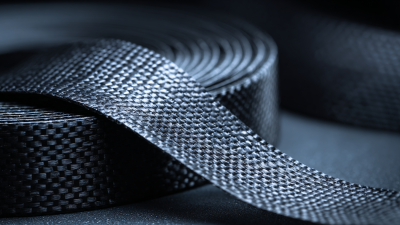

Pultruded carbon fiber rods have emerged as a revolutionary material in modern engineering, particularly noted for their exceptional corrosion resistance. Unlike traditional materials such as steel or aluminum, carbon fiber rods are less susceptible to chemical degradation, making them ideal for applications in harsh environments. This inherent property ensures that structures utilizing these rods maintain their integrity over time, reducing the need for frequent replacements and extensive maintenance.

In addition to their durability, pultruded carbon fiber rods provide a lightweight alternative to heavier materials. This characteristic not only simplifies transportation and installation but also enables engineers to design more efficient structures without compromising strength. In industries such as marine, chemical processing, and infrastructure, the combination of lightweight and corrosion-resistant materials leads to innovations that withstand the test of time, ultimately contributing to safety and sustainability in modern engineering practices.

Pultruded carbon fiber rods are revolutionizing modern engineering applications, particularly due to their enhanced electrical and thermal insulation properties. These rods are not only lightweight and strong but also exhibit impressive thermal resistance, making them ideal for sectors such as aerospace and electronics. According to a report by the Composites Manufacturing Association, carbon fibers can maintain their structural integrity at temperatures exceeding 300°C, while traditional materials often fail under such conditions. This capability allows engineers to design more efficient systems without the risk of overheating or component failure.

In addition to thermal benefits, pultruded carbon fiber rods possess remarkable electrical insulation properties. Their dielectric strength is significantly higher than that of traditional metals, providing a safer alternative for applications where electrical conductivity must be minimized. For instance, electrical engineers have noted that using carbon fiber in high-voltage environments reduces the risk of short circuits and equipment malfunctions, enhancing overall system reliability.

**Tips for Engineers**: When considering materials for projects requiring high thermal and electrical insulation, always test the specific carbon fiber product against other materials in your application’s environment. Additionally, take advantage of simulation tools to model performance under extreme conditions before finalizing your design.

In modern engineering projects, the choice of materials can significantly impact both performance and maintenance costs. Pultruded carbon fiber rods have emerged as a game-changer in this respect. Their intrinsic properties, such as high tensile strength and low weight, contribute to their capability to withstand fatigue over extended periods. This durability translates into fewer breakdowns and a reduction in the frequency of replacements, ultimately leading to lower maintenance costs.

In modern engineering projects, the choice of materials can significantly impact both performance and maintenance costs. Pultruded carbon fiber rods have emerged as a game-changer in this respect. Their intrinsic properties, such as high tensile strength and low weight, contribute to their capability to withstand fatigue over extended periods. This durability translates into fewer breakdowns and a reduction in the frequency of replacements, ultimately leading to lower maintenance costs.

Moreover, the resistance of carbon fiber rods to environmental factors further enhances their longevity. Unlike traditional materials, these rods do not corrode, warp, or swell, even when exposed to harsh conditions. This resilience is particularly beneficial in long-term projects, where consistent performance is critical. By minimizing the need for regular inspections and repairs, engineers can allocate resources more efficiently, ensuring that projects remain within budget and timelines. The use of pultruded carbon fiber rods not only optimizes structural integrity but also significantly reduces the long-term financial burden associated with maintenance and fatigue-related failures.

Pultruded carbon fiber rods have emerged as a game-changer in modern engineering due to their remarkable properties and versatility. One of the standout features is their customization potential. Engineers can easily tailor these rods to specific dimensions and mechanical properties, ensuring that they perfectly fit the requirements of diverse applications. Whether it’s for structural components in aerospace engineering or specialty tooling in manufacturing, the ability to customize pultruded rods can lead to optimized performance and efficiency.

When fabricating these rods, the process is relatively straightforward. This ease of fabrication allows for rapid prototyping and development, enabling engineers to quickly iterate designs without the long lead times often associated with traditional materials. The infusion of unique resins into the carbon fiber during production further enhances its attributes, resulting in a lightweight yet robust solution.

Tips: When considering pultruded carbon fiber rods for your project, always assess the specific mechanical properties you require, such as tensile strength and flexibility. Additionally, collaborating with manufacturers who specialize in custom solutions can yield innovative designs that cater to your project's needs. Lastly, experimenting with various resin formulations can result in enhanced performance characteristics suitable for your engineering challenges.