-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In recent years, the emergence of Carbon Fiber Composites has revolutionized various industries, from aerospace to automotive engineering. These advanced materials, known for their exceptional strength-to-weight ratio and versatility, offer a plethora of benefits that go beyond traditional materials. While many are aware of the key advantages, such as reduced weight and enhanced durability, there are several lesser-known benefits that truly define the potential of Carbon Fiber Composites.

In this article, we will explore the top ten benefits of Carbon Fiber Composites that may have flown under the radar for many. From their superior resistance to environmental factors to cost-effectiveness in the long run, the remarkable properties of these composites are paving the way for innovation and improved performance across various applications. As we delve into these benefits, you will gain a deeper understanding of why Carbon Fiber Composites are becoming the material of choice in modern manufacturing and design. Whether you are an industry professional or simply curious about material science, these insights will highlight the significant role that Carbon Fiber Composites play in shaping the future.

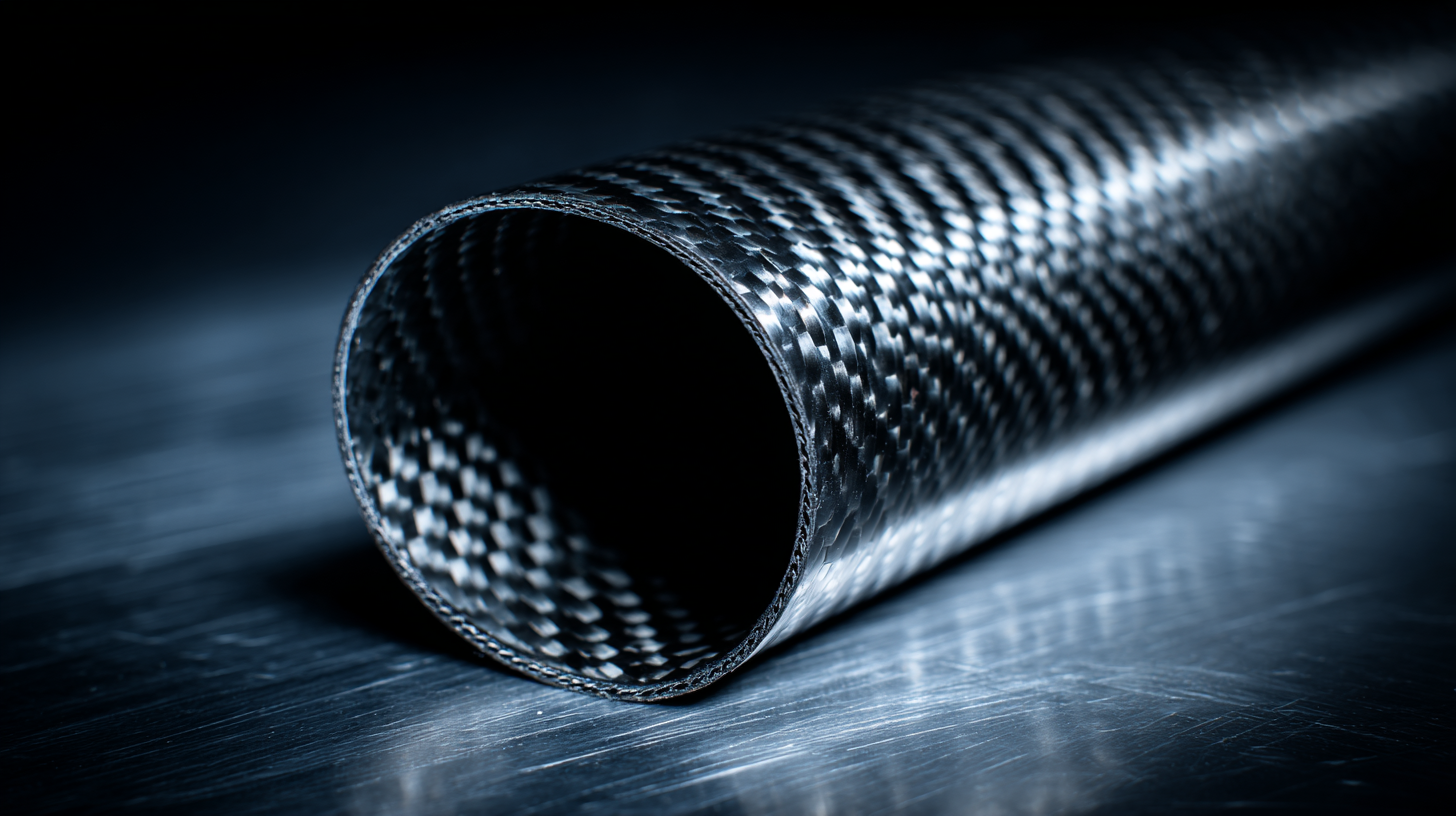

Carbon fiber composites are heralded for their unparalleled strength-to-weight ratio, making them a game-changer in various industries. Unlike traditional materials such as steel or aluminum, carbon fiber offers the same structural integrity at a fraction of the weight. This unique property allows manufacturers to create lighter, stronger components, which translates to enhanced performance in applications ranging from aerospace to automotive. Vehicles built with carbon fiber can achieve better fuel efficiency and accelerated speeds, while airplanes benefit from reduced weight, resulting in lower operational costs and improved aerodynamics.

Moreover, the innovative use of carbon fiber composites is revolutionizing product design and manufacturing processes. By enabling more complex shapes and reducing the need for excess material, designers can create more efficient structures that do not sacrifice durability. This not only streamlines production but also minimizes waste, aligning with modern sustainability efforts. As industries continue to embrace carbon fiber composites, we see a paradigm shift towards higher efficiency and performance across various sectors, showcasing the material’s transformative potential.

Carbon fiber composites stand out due to their exceptional corrosion resistance, which significantly extends the lifespan of various products. Unlike traditional materials, carbon fiber does not rust or corrode, making it an ideal choice for industries such as aerospace, marine, and automotive. This inherent durability means that products made from carbon fiber composites can withstand harsh environmental conditions, including moisture, salt, and chemicals, ultimately reducing maintenance costs and the frequency of replacements.

When considering carbon fiber for your projects, keep in mind a few tips to maximize its benefits. First, ensure proper handling and storage of the materials to prevent any potential damage before assembly. Second, while the corrosion resistance is impressive, pairing carbon fiber with compatible materials can enhance overall performance and prevent galvanic corrosion. Lastly, consulting with experts during the design phase can help identify the best applications for carbon fiber composites, optimizing both durability and functionality in your products.

Carbon fiber composites have revolutionized engineering design by offering unprecedented flexibility that enables innovative solutions across various industries. With a high strength-to-weight ratio, carbon fiber allows engineers to create lightweight yet durable structures. A report by MarketsandMarkets projects that the carbon fiber market will grow from USD 3.6 billion in 2020 to USD 6.3 billion by 2025, reflecting the increasing demand for materials that facilitate innovative engineering approaches. This material’s adaptability is critical in industries like aerospace and automotive, where complex geometries and unique designs are necessary to enhance performance and efficiency.

Moreover, the versatility of carbon fiber composites allows for custom-tailored designs that were previously unattainable with traditional materials. According to a 2022 study published in the Journal of Composite Materials, over 70% of aerospace engineers reported that the design flexibility provided by carbon fiber composites significantly improved their ability to meet performance criteria and reduced time-to-market for new products. This capacity to mold carbon fiber into intricate shapes without compromising structural integrity has opened new avenues for advancements in product design, enabling the development of innovative engineering solutions that could redefine industry standards.

This chart illustrates the top benefits of carbon fiber composites, highlighting their significant advantages in various engineering applications.

Enhanced damping properties in carbon fiber composites have garnered significant attention in various industries, particularly in vibration control applications. Recent studies highlight that carbon fiber reinforced polymers (CFRPs) can achieve exceptional damping capabilities through specific surface treatments, resulting in improved mechanical performance and vibration isolation. For instance, research indicates that certain modifications to the surface of CFRPs can elevate their damping ratios significantly, making them suitable for high-performance applications in automotive and aerospace sectors where vibration management is crucial for safety and efficiency.

The vibration damping materials market is projected to grow considerably, with reports estimating an increase from USD 1.5 billion in 2021 to USD 2.3 billion by 2026. This growth is driven by the rising demand for effective vibration control solutions in industries like automotive, where vibration can lead to reduced comfort and increased wear on mechanical components. Emerging technologies, such as the development of innovative double-resonator phononic crystals and 3D-printed bistable mechanisms, are set to revolutionize vibration isolation strategies, offering superior low-frequency vibration attenuation, which is a common challenge faced in heavy machinery and firearms, where recoil can significantly impact performance and user experience.

The advent of carbon fiber composites has brought a transformative shift in various industries, particularly due to their sustainable manufacturing practices. Unlike traditional materials such as metals and plastics, carbon fiber can be produced using eco-friendly methods that significantly reduce carbon emissions. According to a report by MarketsandMarkets, the global carbon fiber market is projected to reach $7.8 billion by 2025, driven in part by its increasing adoption in the automotive and aerospace sectors, which are actively seeking to minimize their environmental footprints.

Moreover, the lifecycle of carbon fiber composites underscores their sustainability potential. These materials are not only lightweight and durable but also recyclable, which adds to their eco-friendly credentials. A 2022 study published in the Journal of Cleaner Production highlighted that recycling carbon fiber can reduce energy consumption by up to 60% compared to producing new composites. As industries continually strive for greener practices, the integration of carbon fiber composites with sustainable production and recycling processes is likely to play a pivotal role in achieving environmental goals while enhancing product performance.