-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

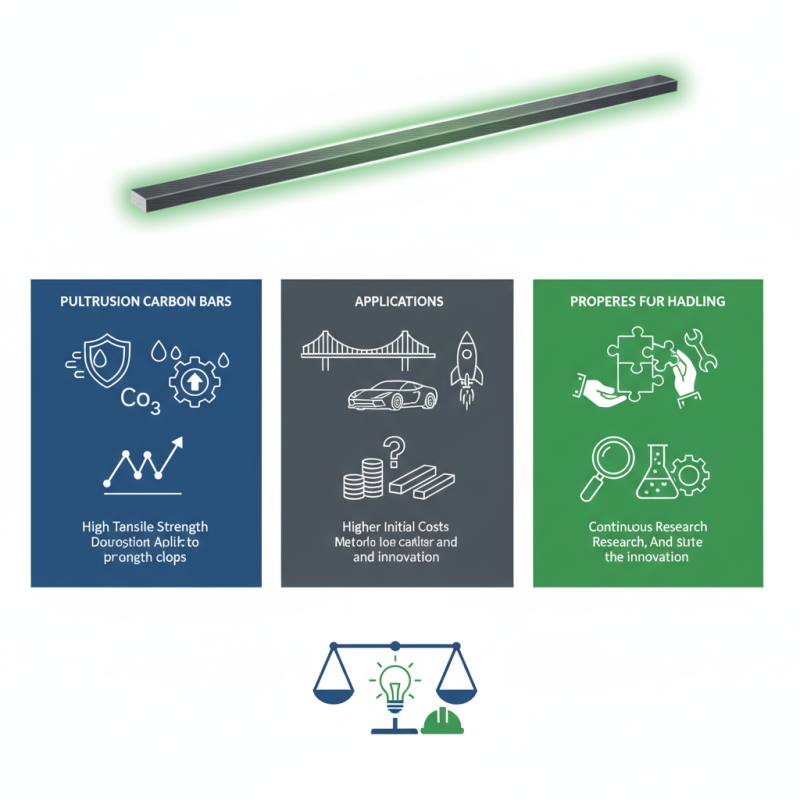

The Pultrusion Carbon Fiber Bar has emerged as a revolutionary solution in various industries. With its lightweight yet robust properties, this bar offers significant advantages over traditional materials. According to a report from MarketsandMarkets, the demand for carbon fiber composites is expected to reach 3.5 billion USD by 2025. This growth highlights the increasing reliance on advanced materials like pultruded carbon fiber.

One of the key benefits of Pultrusion Carbon Fiber Bars is their corrosion resistance. Unlike metals, these bars do not rust or degrade under harsh environmental conditions. In addition, they have excellent tensile strength, offering applications in construction, automotive, and aerospace sectors. However, while these benefits are compelling, the initial costs can be higher than alternatives. Companies must weigh these factors carefully.

Incorporating Pultrusion Carbon Fiber Bars into projects requires expertise. Understanding the proper handling and installation is crucial. Missteps here can lead to reduced performance or failures. As the industry evolves, continuous research is needed to address these challenges and enhance usability. Striking a balance between innovation and practicality will determine the future of this remarkable material.

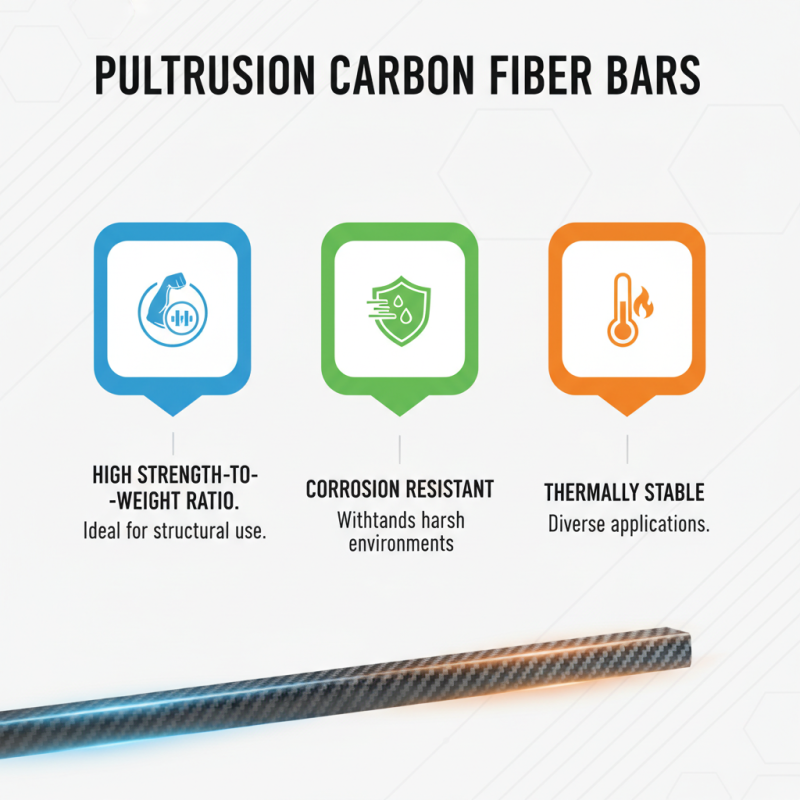

Pultrusion carbon fiber bars offer numerous advantages across various industries. Their lightweight nature, combined with high strength-to-weight ratios, makes them ideal for applications in construction and automotive sectors. According to a recent industry report, carbon fiber composites can be up to five times stronger than steel while weighing only 25% as much. This characteristic leads to enhanced fuel efficiency in vehicles and reduced structural loads in buildings.

Furthermore, pultruded carbon fiber bars exhibit excellent corrosion resistance and durability. They outperform traditional materials, especially in harsh environments. This capability improves longevity, thus lowering maintenance costs. For instance, in the marine industry, using carbon fiber bars can extend the life of boat components, making them a long-term investment.

When using pultrusion carbon fiber bars, it’s crucial to consider proper handling. These materials can be sensitive to UV exposure, which may lead to eventual degradation. Storing them in a shaded area is a smart practice. Additionally, ensure that the components are installed correctly to maximize their strength. Always refer to manufacturer guidelines for specific applications to avoid potential pitfalls.

Pultrusion carbon fiber bars offer remarkable advantages in various applications. Their high strength-to-weight ratio makes them ideal for structural use. These bars resist corrosion and can withstand harsh environments. Their thermal stability further enhances usability in diverse scenarios.

When using pultrusion carbon fiber bars, consider the specific properties essential for your project. Their stiffness affects how they perform under load. Different applications may require varying stiffness levels. You should evaluate loading conditions thoroughly.

Tips: Always check the compatibility of carbon fiber with other materials. A mismatch can lead to premature failure. Proper handling is crucial. Carbon fiber can splinter, so wear protective gear. Test your design with smaller samples before full-scale application. This can save time and resources in the long run.

Selecting the right pultrusion carbon fiber bar requires careful consideration. First, assess the specific application. Will it face high stress or environmental exposure? Understanding the demands can help in making an informed choice.

Next, consider the bar's dimensions. Length, width, and thickness all play a crucial role. Ensure the dimensions match your project needs. An incorrect size can lead to inefficiencies and frustrations. Don't overlook the weight. Lighter bars are often preferable, but compromise might occur in strength.

Finally, evaluate the manufacturing process. Different pultrusion techniques can affect the bar's properties. Some may offer better consistency, while others might allow for unique designs. Research and reflect on these aspects. Always be open to exploring new options, as each choice has its own set of pros and cons.

Pultrusion carbon fiber bars offer significant benefits in various applications. When using these bars, it’s important to follow best practices to ensure optimal performance. First, always inspect the bars for any visible damages. A small crack can undermine the entire structure.

Next, ensure you have the right tools before starting your project. Using inappropriate tools can lead to uneven cuts or weak joints.

Proper storage is also essential. Keep the bars in a dry environment. High humidity can affect their integrity. When cutting, maintain a steady hand. Rushing can result in inconsistent lengths. Additionally, consider the right adhesive for joining sections. A weak bond could compromise strength.

Lastly, always test the finished structure under controlled conditions. It's wise to verify if changes are needed. Feedback loops from testing can enhance future projects. Working with pultrusion carbon fiber bars can be rewarding, but attention to detail is crucial for success.

Maintaining carbon fiber bars is crucial for their longevity and performance. Regular inspections are essential. Look for any signs of wear, including cracks or chips. If you spot damage, address it immediately. Minor issues can lead to larger problems if ignored.

Cleaning is simple but important. Use mild soap and warm water for surface cleaning. Avoid harsh chemicals; they can degrade the material. A soft cloth works best. Rinse thoroughly with clean water after washing. Dry off completely to prevent moisture buildup.

Store carbon fiber bars properly. Keep them in a cool, dry place. Extreme temperatures can affect their integrity. Avoid placing heavy objects on them. Sometimes, we forget how sensitive these materials are. Use padded cases if you transport them frequently. Reflecting on handling practices can lead to better care.

The above bar chart illustrates the various benefits of pultrusion carbon fiber bars, rated on a scale from 1 to 10. Lightweight properties and high strength are the most advantageous features, making these bars ideal for various applications.