-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

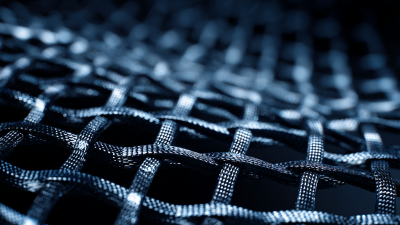

In recent years, the advancement of materials science has led to the emergence of innovative solutions in various industries, with Carbon Fiber Webbing standing out due to its exceptional properties and versatility. According to a report by Markets and Markets, the global carbon fiber market is projected to reach $5.73 billion by 2026, growing at a CAGR of 9.5%, driven largely by the increasing demand for lightweight yet strong materials in sectors such as aerospace, automotive, and outdoor gear.

Unlike traditional materials such as nylon or polyester, Carbon Fiber Webbing offers superior strength-to-weight ratios, increased durability, and enhanced resistance to environmental factors, making it an ideal choice for applications that require reliability and performance. This blog will explore the advantages of Carbon Fiber Webbing over its traditional counterparts, highlighting its unique characteristics and the opportunities it presents across various industries.

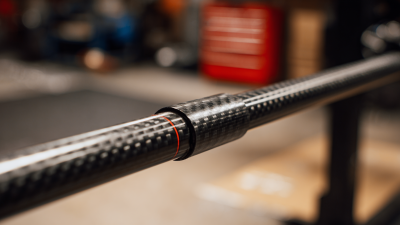

Carbon fiber webbing has emerged as a formidable contender in the material world, particularly due to its exceptional strength-to-weight ratio. Reports indicate that carbon fiber can be up to five times stronger than steel while being significantly lighter; typically, it weighs only about one-seventh of the weight of steel. This remarkable property makes carbon fiber webbing an excellent choice for various applications, from aerospace to sporting goods, ensuring that structural integrity is maintained without the burden of excess weight. Furthermore, its tensile strength can reach up to 600 MPa, surpassing many traditional materials.

When selecting materials for your projects, consider integrating carbon fiber webbing to optimize performance. **Tip 1:** Always assess the specific strength requirements of your application. The superior rigidity and low weight make it ideal for high-performance uses. **Tip 2:** For those concerned with environmental impact, note that carbon fiber can greatly reduce weight in automotive applications, leading to improved fuel efficiency. Embracing such innovative materials not only enhances efficiency but also aligns with modern sustainability goals.

| Material Type | Strength (MPa) | Weight (g/m2) | Strength-to-Weight Ratio (MPa/g/m2) | Durability (Years) |

|---|---|---|---|---|

| Carbon Fiber Webbing | 4800 | 200 | 24 | 20 |

| Aluminum Webbing | 350 | 800 | 0.44 | 15 |

| Polyester Webbing | 350 | 500 | 0.70 | 10 |

| Nylon Webbing | 200 | 600 | 0.33 | 8 |

Carbon fiber webbing is rapidly gaining traction in various industries due to its superior durability compared to traditional materials such as nylon, polypropylene, or polyester. According to a report from the Composites World, carbon fiber is known for its impressive strength-to-weight ratio; it is about five times stronger than steel while being significantly lighter. This characteristic not only enhances the longevity of products made with carbon fiber webbing but also reduces the overall weight, making it particularly appealing for applications in aerospace and automotive sectors.

Moreover, the fatigue resistance of carbon fiber webbing is noteworthy. A study published by the Journal of Advanced Materials highlighted that carbon fiber exhibits less deformation over extended use, ensuring that products maintain their integrity even under heavy duress. In contrast, traditional fabrics can suffer from wear and tear more quickly, leading to potential failures. This durability translates into lower maintenance costs and reduced need for replacements, enabling manufacturers to realize significant long-term savings. As industries continue to emphasize performance and sustainability, carbon fiber webbing is poised to redefine standards of durability and reliability.

Carbon fiber webbing is making waves across multiple industries, thanks to its unique properties that offer flexibility and strength. In the automotive sector, for example, manufacturers are increasingly using carbon fiber webbing to enhance vehicle performance while reducing overall weight. This not only improves fuel efficiency but also contributes to better handling and safety, making it an appealing option for modern car designs.

Carbon fiber webbing is making waves across multiple industries, thanks to its unique properties that offer flexibility and strength. In the automotive sector, for example, manufacturers are increasingly using carbon fiber webbing to enhance vehicle performance while reducing overall weight. This not only improves fuel efficiency but also contributes to better handling and safety, making it an appealing option for modern car designs.

In the sporting goods industry, carbon fiber webbing is revolutionizing the design of equipment such as bicycles, fishing rods, and archeries. Its lightweight nature coupled with high tensile strength allows athletes to perform at their best while minimizing strain and injury risk. Moreover, the ability to mold carbon fiber into intricate shapes means that designers can create more innovative and performance-enhancing products, catering to the evolving needs of professional and amateur athletes alike.

Additionally, carbon fiber webbing finds applications in aerospace, where the demand for materials that are both lightweight and durable is paramount. It is instrumental in manufacturing components for aircraft, contributing to increased fuel efficiency and reduced emissions. By embracing carbon fiber, various industries are not only optimizing their products but also paving the way for sustainable advancements in material technology.

When considering materials for various applications, cost-effectiveness is often a major concern for businesses and consumers alike. Carbon fiber webbing stands out as an advantageous option in this regard, providing long-term savings that surpass traditional materials like nylon or polyester. While the initial investment in carbon fiber webbing may seem higher, its exceptional durability and lightweight properties lead to reduced maintenance costs and longer product lifespans.

Traditional materials often degrade under stress, requiring frequent replacements and repairs that can accumulate significant expenses over time. In contrast, carbon fiber webbing is resistant to environmental factors such as UV rays and moisture, ensuring that products made from this material retain their integrity for prolonged periods. Furthermore, the reduced weight of carbon fiber webbing can enhance overall performance and efficiency, particularly in applications where weight savings are crucial, such as in automotive or aerospace industries. By choosing carbon fiber, users not only invest in a superior product but also realize financial benefits that compound over time, ultimately making it a smart choice for both short- and long-term projects.

This chart illustrates the average cost per meter of various webbing materials, highlighting the cost-effectiveness of carbon fiber webbing compared to traditional options such as nylon, polyester, and cotton. While carbon fiber may present a higher initial cost, its durability and strength lead to long-term savings.

Carbon fiber webbing offers significant sustainability benefits compared to traditional materials, making it an appealing choice for various industries. Recent studies highlight the mechanical properties and eco-friendly advantages of bioresin-based composites that incorporate carbon fiber alongside natural fibers. Such innovations not only enhance material performance but also reduce reliance on petroleum-based products. For example, the incorporation of carbon fiber allows for lighter constructions, which can lead to lower energy consumption during use, especially in sectors like automotive and aerospace.

Moreover, the ongoing research into recycled carbon fiber demonstrates a promising shift toward sustainable practices. The life-cycle assessment of alternative materials for trains shows that utilizing recycled carbon fiber can mitigate environmental impacts significantly while maintaining structural integrity. Such examples underline the trend of sustainability being integrated into composite manufacturing—where both high-performance outcomes and eco-responsibility are prioritized. As industries continuously seek materials that minimize carbon footprints, carbon fiber webbing stands out as a critical player in fostering a greener future, backed by ongoing innovations in recycling and sustainable practices.